Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

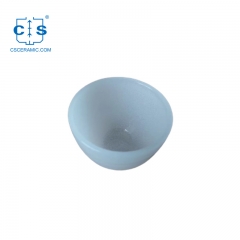

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

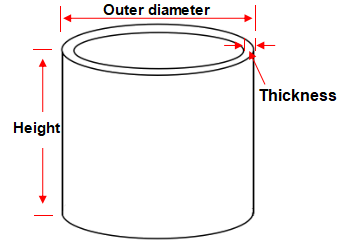

Read Moreitem no. :

CS-QTZ-A001Material : Quartz glass

Purity Available : 99.99%

Shape : Cylindrical

Cover/Lid : Can be equipped

Advantages of transparent cylindrical quartz crucible:

1. High temperature resistance: Cylindrical quartz glass crucible can withstand a high temperature without cracking or melting. Long term use at 1100 ℃, short term use at 1450 ℃.

2. Corrosion resistance: Quartz glass is highly corrosion-resistant to almost all acids, alkalis, and other harsh chemicals. This makes it ideal for use in chemical processes that involve aggressive chemicals.

3. Low thermal expansion: It has a low coefficient of thermal expansion. This means that it does not expand significantly when heated, which reduces the risk of cracking due to thermal shock.

4. Durable: Cylindrical quartz glass crucible is highly durable and can last for many years with proper care and maintenance.

5. Optically transparent: It is optically transparent, which allows for easy observation of the contents inside the crucible. This is particularly useful in applications like crystal growth.

Descriptions of transparent cylindrical quartz crucible:

1. Cylindrical quartz glass crucibles are specialized containers made specifically for high-temperature applications such as melting or heating materials within a laboratory setting.

2. These crucibles are made of high-purity quartz glass, which provides exceptional resistance to thermal shock, corrosion, and chemical attack.

3. The cylindrical shape of these crucibles allows for efficient use of space in the laboratory while providing ample space for sample preparation and experimentation.

4. The smooth and polished interior of these crucibles is ideal for preventing chemical reactions and minimizing the risk of contamination during high-temperature experiments.

Size details of transparent cylindrical quartz crucible:

Cylindrical Quartz Glass Crucible

Item NO.

Purity

Item NO.

Purity

CS-QTZ-A001

0.7

20

4

1.5

99.99%

CS-QTZ-A029

12

54

8

2

99.99%

CS-QTZ-A002

0.6

12

8

1.5

99.99%

CS-QTZ-A030

6

17

37

2

99.99%

CS-QTZ-A003

0.9

12

12

1.5

99.99%

CS-QTZ-A031

9

16

60

2

99.99%

CS-QTZ-A004

0.8

12

10

1.5

99.99%

CS-QTZ-A032

7.5

20

30

2

99.99%

CS-QTZ-A005

0.9

20

5

1.5

99.99%

CS-QTZ-A033

7

22

25

2

99.99%

CS-QTZ-A006

0.7

12

10

1.5

99.99%

CS-QTZ-A034

10

25

25

2

99.99%

CS-QTZ-A007

1.4

18

8

1.5

99.99%

CS-QTZ-A035

9

20

40

2

99.99%

CS-QTZ-A008

1.3

11

20

1.5

99.99%

CS-QTZ-A036

12

19

58

2

99.99%

CS-QTZ-A009

1.6

12

20

1.5

99.99%

CS-QTZ-A037

16

30

28

2

99.99%

CS-QTZ-A010

1.7

9

40

1.5

99.99%

CS-QTZ-A038

17

47

13

2

99.99%

CS-QTZ-A011

1.5

13

25

1.5

99.99%

CS-QTZ-A039

20

23

60

2

99.99%

CS-QTZ-A012

1.3

10

25

1.5

99.99%

CS-QTZ-A040

17

30

30

2

99.99%

CS-QTZ-A013

5

20

20

1.5

99.99%

CS-QTZ-A041

24.5

25

60

2

99.99%

CS-QTZ-A014

2

30

5

1.5

99.99%

CS-QTZ-A042

23

35

30

2

99.99%

CS-QTZ-A015

6

22

20

1.5

99.99%

CS-QTZ-A043

24

28

58

2

99.99%

CS-QTZ-A016

3.5

18

18

1.5

99.99%

CS-QTZ-A044

28

35

35

2

99.99%

CS-QTZ-A017

4

16

28

1.5

99.99%

CS-QTZ-A045

30

28

58

2

99.99%

CS-QTZ-A018

0.5

15

5

1.5

99.99%

CS-QTZ-A046

35

30

60

2

99.99%

CS-QTZ-A019

1.2

15

10

1.5

99.99%

CS-QTZ-A047

39

36

45

2

99.99%

CS-QTZ-A020

2.6

15

20

1.5

99.99%

CS-QTZ-A048

37

40

35

2

99.99%

CS-QTZ-A021

3.7

17

21

1.5

99.99%

CS-QTZ-A049

36

26

82

2

99.99%

CS-QTZ-A022

5.2

14

44

1.5

99.99%

CS-QTZ-A050

43

40

40

2

99.99%

CS-QTZ-A023

6

32

10

2

99.99%

CS-QTZ-A051

41

40

40

2.5

99.99%

CS-QTZ-A024

2

10

40

2

99.99%

CS-QTZ-A052

54

40

50

2

99.99%

CS-QTZ-A025

6

15

50

2

99.99%

CS-QTZ-A053

52

40

50

2.5

99.99%

CS-QTZ-A026

8

28

17

2

99.99%

CS-QTZ-A054

63

40

60

2.5

99.99%

CS-QTZ-A027

6

35

8.5

2

99.99%

CS-QTZ-A055

130

40

120

2.5

99.99%

CS-QTZ-A028

7

16

50

2

99.99%

CS-QTZ-A056

150

60

60

2.5

99.99%

OEM/ODM is acceptable. Your goods will be produced exactly according to your drawings or inquiry

The crucible can be equipped with a lid. If you need it, please provide your request.

Parameters of quartz crucible:

| Chemical composition: | SiO2 99.99% |

| Density: | 2.2(g/cm3) |

| Degree of hardness moh' scale: | 6.6 |

| Melting point: | 1732℃ |

| Working temperature: | 1100℃ |

| Max temperature can reach in a short time: | 1450℃ |

| Acid tolerance: | 30 times than Ceramics , 150 times than Stainless steel |

| Visible light transmittance: | above 93% |

| UV spectral region transmittance: | 80% |

| Resistance value: | 10000 times than ordinary glass |

| Annealing point: | 1215℃ |

| Softening point: | 1730℃ |

Applications of transparent cylindrical quartz crucible:

1. Chemical synthesis: Cylindrical quartz crucible can be used in the chemical synthesis of various compounds.

2. Sample analysis: It can be employed in the analysis of different types of samples, and provides a clean and inert environment for the sample, reducing the possibility of contamination by other materials. It is also helpful in the analysis of materials that require high temperatures or strong acids, without damaging the container.

3. Metallurgy: Commonly used in metallurgical applications. It can withstand high temperatures and possess excellent thermal shock resistance, making it ideal for melting and casting metals.

4. Jewelry making: Jewelry manufacturers are among the primary users of cylindrical quartz crucible. The high-temperature tolerance and thermal shock resistance of the quartz glass allow for the use of extremely hot flames, necessary for melting precious metals.

5. Semiconductor manufacturing: Used in semiconductor manufacturing. The high transparency and stability of the crucible enable precise control of the manufacturing process, which is crucial for producing high-quality semiconductors.

6. Gems and stones production: Widely used in the production of gems and stones. It is used in the melting of materials like synthetic sapphires, rubies and other precious gems, producing high-quality products with exceptional clarity and colour.

7. Pharmaceuticals: The quartz crucible may also be used in pharmaceutical manufacturing. It can be employed in high-pressure and high-temperature reactions that is crucial in the production of certain drug compounds.

8. Powder metallurgy: Powder metallurgy refers to the production of metallic components through powder processing.

9. Aerospace industry: Aerospace applications that require high-temperature testing and development can also utilize cylindrical quartz glass crucible.

10. Thermal testing: Quartz glass crucible offers excellent thermal shock resistance, making it perfect for use in thermal testing. These applications may include testing the resistance of materials to sudden temperature changes, high-temperature fluid dynamics testing or to determine the properties of materials at high temperature levels.

FAQ

Q1. What information should we supply to get a quote?

Please offer the specification of quartz glass crucible, such as shape, dimension, quantity, application etc.

Q2. How do you handle cylindrical quartz glass crucibles?

Cylindrical quartz glass crucibles should be handled with care to avoid any physical damage. They should be held by the outer edges using suitable gloves or tongs, and not dropped or knocked against hard surfaces.

Q3. How do you store cylindrical quartz glass crucibles?

Cylindrical quartz glass crucibles should be stored in a clean and dry place to prevent any contamination or damage. They should be stacked carefully to avoid any physical damage.

Q4. Are these crucibles reusable?

Yes, these crucibles are highly durable and can be reused multiple times, as long as they are properly cleaned and maintained.

How to clean transparent cylindrical quartz crucible:

1. Remove any remaining material from the crucible using a soft brush or soft cloth.

2. Fill a container with warm water and add a small amount of detergent.

3. Submerge the crucible in the detergent water and let it soak for several minutes.

4. Use a soft brush or cloth to gently scrub the inside and outside of the crucible, paying special attention to any stubborn stains or deposits.

5. Rinse the crucible thoroughly with clean water to remove all detergent residue.

6. Dry the crucible with a soft cloth or let it air dry.

7. Store the clean and dry crucible in a clean, dry location until its next use.

Quality testing standards:

1. Visual inspection of the crucible for any signs of damage or irregularities.

2. Measurement of the length, width, and thickness of the crucible to check for accuracy.

3. Hold the crucible against a light source and inspect it for transparency. Transparent quartz glass should allow light to pass through it easily with little to no distortion.

4. Pour a small amount of water on the surface of the crucible and observe the behavior of the water. If the water beads up and does not properly wet the surface of the crucible, it may indicate a coating of impurities on the surface.

5. Verification of the material and chemical composition of the crucible.

Packing way:

Why Choose us?

1. We supply personalized and customized services to contact your personal needs.

2. We are experienced professionals with a good record of success.

3. We provide superior client service and promptly respond to all inquiries.

4. We provide militant prices and strive to ensure that your funds receive the best value.

5. We use the latest technologies and tools to ensure that your project is completed to the highest standards.

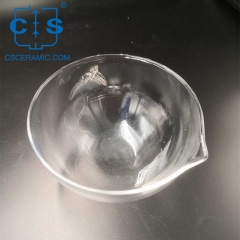

99.99% Transparent Conical Quartz Crucible with Lid SiO2 Glass Crucibles

99.99% Transparent Conical Quartz Crucible with Lid SiO2 Glass Crucibles

Conical quartz glass crucibles are made from high purity quartz glass and are conically shaped,this design allows for efficient heat transfer and uniform distribution of heat throughout the crucible,available in various sizes.

99.99% Transparent Square Quartz Glass Crucibles Silica Crucibles

99.99% Transparent Square Quartz Glass Crucibles Silica Crucibles

Square quartz glass crucibles have a perfectly square design,offers more space for samples and ensures uniform heating,making them an ideal choice for precision experiments and studies.Available in various sizes.

99.98% 99.99% Transparent Quartz Boats SiO2 Glass boats

99.98% 99.99% Transparent Quartz Boats SiO2 Glass boats

Quartz boats are inert to most chemicals, including acids, alkalis, and organic solvents. They are easy to clean, sterilize, and reuse.Available in various sizes and shapes, from miniature crucibles to larger containers.

Opaque Quartz Crucible

Opaque Quartz Crucible

Opaque Quartz Crucibles are laboratory consumables, which used for holding and heating materials in laboratories.

High-Purity Fused Quartz Crucible for Silicon Crystal Pulling in Semiconductor & PV

High-Purity Fused Quartz Crucible for Silicon Crystal Pulling in Semiconductor & PV

The high-purity quartz crucible, super clean & heat-resistant, ensures stable performance at high temps, crucial for semiconductor & photovoltaic processes, holding molten silicon to pull crystal rods.

High-Temp Quartz Lab Dish Evaporation & Crystallization Tool

High-Temp Quartz Lab Dish Evaporation & Crystallization Tool

The high-temp, corrosion-resistant quartz evaporating dish adapts to harsh environments, ensuring reliable evaporation, concentration, and crystallization of solutions.

Transparent 99.98% Quartz Glass Beaker

Transparent 99.98% Quartz Glass Beaker

99.98% quartz glass beaker has high economic benefits,and is an essential piece of equipment for any laboratory or research facility requiring precise measurements and accurate results.Available in various sizes.

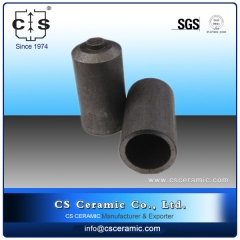

Graphite Crucible 780-890 Alpha AR7808

Graphite Crucible 780-890 Alpha AR7808

LECO 780-890 Graphite Crucible, Alpha AR7808 For LECO OHN-836. Manufacturer of LECO Alpha Graphite Crucible.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522