Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read Moreitem no. :

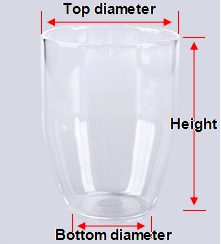

CS-QTZ-B001Material : Quartz glass

Purity Available : 99.99%

Shape : Conical

Volume : 5-500ml; OEM

Advantages of conical quartz crucible with lid:

1. Heat resistant: Conical quartz glass crucible with lid is highly heat-resistant, suitable for high-temperature applications.

2. Resistant to thermal shock: It is able to withstand sudden or rapid changes in temperature without breaking or cracking.

3. Durability: Conical quartz glass crucible is highly durable and can withstand long-term use without losing its structural integrity.

4. High purity: Quartz glass is highly pure, meaning that it does not introduce any impurities into the samples being tested or heated.

5. Optically clear: Conical quartz glass crucible with lid is optically clear, allowing for easy observation of the materials being heated or tested.

Descriptions of conical quartz crucible with lid:

1. Conical quartz glass crucible with lid is laboratory containers used for heating, melting, and mixing chemicals and compounds.

2. The crucible is conically shaped, with a large opening at the top and a tapering body leading down to a narrow point at the bottom.

3. This design allows for efficient heat transfer and uniform distribution of heat throughout the crucible.

4. Conical quartz glass crucible with lid is available in various sizes and capacities, depending on the specific application requirements.

Size details of conical quartz crucible:

Conical Quartz Glass Crucible

Item NO.

Purity

CS-QTZ-B001

5

25

18

31

1.5

99.99%

CS-QTZ-B002

5

25

18

40

1.5

99.99%

CS-QTZ-B003

10

30

23

42

2

99.99%

CS-QTZ-B004

10

30

23

53

2

99.99%

CS-QTZ-B005

20

35

25

45

2

99.99%

CS-QTZ-B006

20

35

25

59

2

99.99%

CS-QTZ-B007

30

40

30

54

2

99.99%

CS-QTZ-B008

30

40

30

68

2

99.99%

CS-QTZ-B009

50

45

33

63

2

99.99%

CS-QTZ-B010

50

45

33

75

2

99.99%

CS-QTZ-B011

100

54

39

84

2

99.99%

CS-QTZ-B012

100

54

39

100

2

99.99%

CS-QTZ-B013

150

60

43

90

2

99.99%

CS-QTZ-B014

150

60

43

105

2

99.99%

CS-QTZ-B015

200

69

46

91

2.5

99.99%

CS-QTZ-B016

200

69

46

110

2.5

99.99%

CS-QTZ-B017

250

75

50

110

2.5

99.99%

CS-QTZ-B018

250

75

50

130

2.5

99.99%

CS-QTZ-B019

300

80

51

111

2.5

99.99%

CS-QTZ-B020

300

80

51

130

2.5

99.99%

CS-QTZ-B021

500

88

67

137

2.5

99.99%

CS-QTZ-B022

500

88

67

160

2.5

99.99%

OEM/ODM is acceptable. Your goods will be produced exactly according to your drawings or inquiry.

Parameters of quartz crucible:

| Chemical composition: | SiO2 99.9% |

| Density: | 2.2(g/cm3) |

| Degree of hardness moh' scale: | 6.6 |

| Melting point: | 1732℃ |

| Working temperature: | 1100℃ |

| Max temperature can reach in a short time: | 1450℃ |

| Acid tolerance: | 30 times than Ceramics , 150 times than Stainless steel |

| Visible light transmittance: | above 93% |

| UV spectral region transmittance: | 80% |

| Resistance value: | 10000 times than ordinary glass |

| Annealing point: | 1215℃ |

| Softening point: | 1730℃ |

Applications of conical quartz crucible with lid:

1. Chemical synthesis: Conical quartz glass crucible with lid can be used in chemical synthesis applications that require high purity and resistance to thermal shock. These crucibles can be used to hold and heat reactants, and to contain reaction products under controlled conditions.

2. Analytical chemistry: They are ideal for analytical chemistry applications that require high sensitivity and accuracy. These crucibles can be used for sample preparation, digestion, and fusion, and to contain highly reactive or corrosive samples that would otherwise damage standard glassware.

3. Pyrolysis: They are highly resistant to thermal shock and can be used for high-temperature pyrolysis of organic materials.

4. Materials science: They are used in materials science applications for the production of high-purity materials such as semiconductors and optical fibers. These crucibles can be used to hold and heat precursor materials, and to contain the final product during processing.

5. Environmental analysis: Used in environmental analysis applications to measure the presence and concentration of various pollutants in air or water samples. These crucibles can withstand high temperatures and corrosive chemicals, making them ideal for use in trace analysis applications.

FAQ

Q1. What information should we supply to get a quote?

Please offer the specification of quartz glass crucible, such as shape, dimension, quantity, application etc.

Q2. How do you store quartz glass crucibles?

Quartz glass crucibles should be stored in a clean and dry place to prevent any contamination or damage. They should be stacked carefully to avoid any physical damage.

Q3. Can I heat my conical quartz glass crucible directly on a hot plate or Bunsen burner?

It is not recommended to heat your conical quartz glass crucible directly on a hot plate or Bunsen burner. It is best to use a heating mantle or furnace.

Q4. Is a conical quartz glass crucible reusable?

Yes, a conical quartz glass crucible is reusable, making it a cost-effective option for laboratory applications.

Q5. Are conical quartz glass crucibles compatible with other laboratory equipment?

Yes, conical quartz glass crucibles are compatible with other laboratory equipment such as heating mantles, furnaces, and hot plates.

How to clean conical quartz crucible with lid:

1. Remove any remaining material from the crucible and lid using a soft brush or soft cloth.

2. Fill a container with warm water and add a small amount of detergent.

3. Submerge the crucible in the detergent water and let it soak for several minutes.

4. Use a soft brush or cloth to gently scrub the inside and outside of the crucible and lid, paying special attention to any stubborn stains or deposits.

5. Rinse the crucible thoroughly with clean water to remove all detergent residue.

6. Dry the crucible and lid with a soft cloth or let it air dry.

7. Store the clean and dry crucible in a clean, dry location until its next use.

Quality testing standards:

1. Visual inspection of the crucible for any signs of damage or irregularities.

2. Measurement of the length, width, and thickness of the crucible to check for accuracy.

3. Hold the crucible against a light source and inspect it for transparency. Transparent quartz glass should allow light to pass through it easily with little to no distortion.

4. Pour a small amount of water on the surface of the crucible and observe the behavior of the water. If the water beads up and does not properly wet the surface of the crucible, it may indicate a coating of impurities on the surface.

5. Verification of the material and chemical composition of the crucible.

Packing way:

Why Choose us?

1. We supply personalized and customized services to contact your personal needs.

2. We are experienced professionals with a good record of success.

3. We provide superior client service and promptly respond to all inquiries.

4. We provide militant prices and strive to ensure that your funds receive the best value.

5. We use the latest technologies and tools to ensure that your project is completed to the highest standards.

99.99% Transparent Cylindrical Quartz Crucible Silica Glass Crucibles

99.99% Transparent Cylindrical Quartz Crucible Silica Glass Crucibles

Cylindrical quartz glass crucibles are specialized containers made specifically for high temperature applications, which provides exceptional resistance to corrosion, and chemical attack.Available in various sizes.

99.99% Transparent Square Quartz Glass Crucibles Silica Crucibles

99.99% Transparent Square Quartz Glass Crucibles Silica Crucibles

Square quartz glass crucibles have a perfectly square design,offers more space for samples and ensures uniform heating,making them an ideal choice for precision experiments and studies.Available in various sizes.

99.98% 99.99% Transparent Quartz Boats SiO2 Glass boats

99.98% 99.99% Transparent Quartz Boats SiO2 Glass boats

Quartz boats are inert to most chemicals, including acids, alkalis, and organic solvents. They are easy to clean, sterilize, and reuse.Available in various sizes and shapes, from miniature crucibles to larger containers.

Opaque Quartz Crucible

Opaque Quartz Crucible

Opaque Quartz Crucibles are laboratory consumables, which used for holding and heating materials in laboratories.

High-Purity Fused Quartz Crucible for Silicon Crystal Pulling in Semiconductor & PV

High-Purity Fused Quartz Crucible for Silicon Crystal Pulling in Semiconductor & PV

The high-purity quartz crucible, super clean & heat-resistant, ensures stable performance at high temps, crucial for semiconductor & photovoltaic processes, holding molten silicon to pull crystal rods.

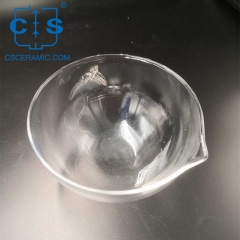

High-Temp Quartz Lab Dish Evaporation & Crystallization Tool

High-Temp Quartz Lab Dish Evaporation & Crystallization Tool

The high-temp, corrosion-resistant quartz evaporating dish adapts to harsh environments, ensuring reliable evaporation, concentration, and crystallization of solutions.

Transparent 99.98% Quartz Glass Beaker

Transparent 99.98% Quartz Glass Beaker

99.98% quartz glass beaker has high economic benefits,and is an essential piece of equipment for any laboratory or research facility requiring precise measurements and accurate results.Available in various sizes.

SiC Roller Tube Core Tool for Supporting & Transporting in Refractory Kiln

SiC Roller Tube Core Tool for Supporting & Transporting in Refractory Kiln

SiC roller tubes, essential refractory kiln tools, support and convey ceramic bodies and products in roller kilns and dryers, serving as the core component of roller furnaces.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522