Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read MoreAlumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

item no. :

CS-A-16Color :

White99.5% 99.7% 99%

Material : Alumina ceramic

1. High temperature resistance: They can withstand temperatures up to 1600℃ in long use(Al2O3≥99%).

2. High electrical insulation: Alumina ceramic substrates have a dielectric constant of 10 and can be used as an insulator for high voltage applications.

3. Low thermal expansion: They have a low coefficient of thermal expansion, making it suitable for applications that require a consistent temperature.

4. Chemical resistance: Highly resistant to corrosion, acids, alkalis, and solvents.

5. High mechanical strength: Highly resistant to mechanical shock and vibration, making it suitable for use in dynamic environments.

6. Low cost: Relatively low cost compared to other materials with similar properties.

1. Alumina ceramic substrates are an extremely durable and reliable material used in a variety of technologies and applications.

2. They are composed of aluminum oxide, which is a stable material with excellent electrical insulation and thermal conductivity properties.

3. Alumina ceramic substrates are ideal for high-heat applications and are often used in advanced electronics and semiconductor packaging.

4. They are also lightweight and easy to work with, making them a popular choice for a wide range of applications.

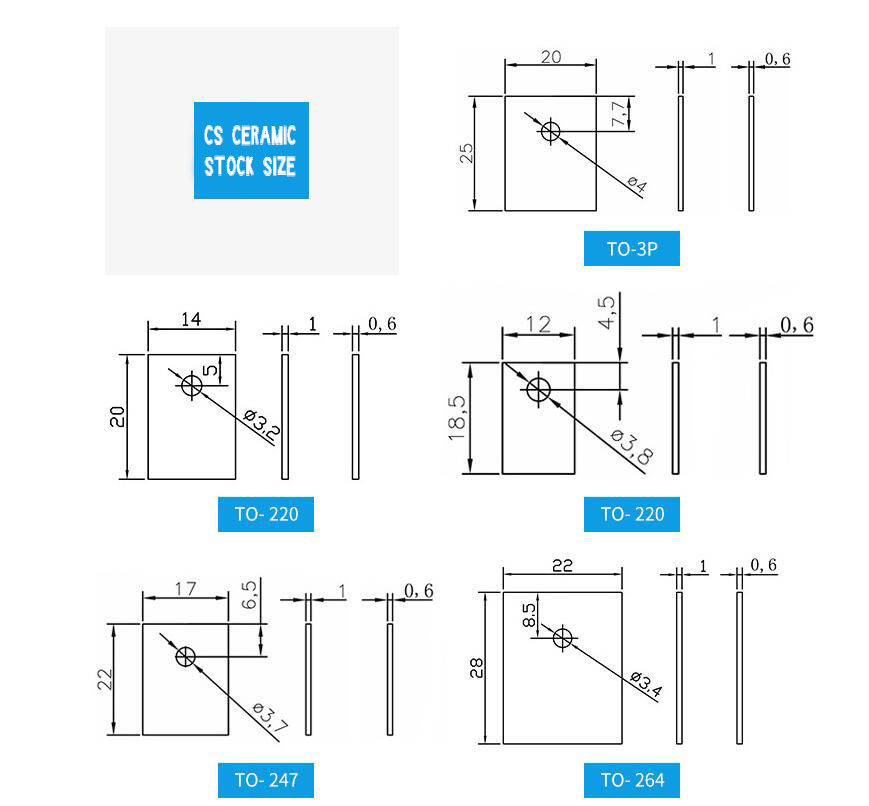

Alumina Ceramic Substrate stock size

Item NO.

Item NO.

Item NO.

Item NO.

Item NO.

CS-J-1

10*2,4*2

CS-J-36

17*22*1 H3.7

CS-J-71

20*25*2 H3.8

CS-J-106

24*104*1

CS-J-141

35*35*20

CS-J-2

10*2.4*1.5

CS-J-37

17*22*0.6 H3.7

CS-J-72

20*28*0.6

CS-J-107

25*34*0.6

CS-J-142

38.5*41*1

CS-J-3

10*15*0.6 H4

CS-J-38

17*22*0.6

CS-J-73

20*28*2

CS-J-108

25*40*1

CS-J-143

39*91*0.6

CS-J-4

10*16*1.5 H3.5

CS-J-39

17*22*1.5

CS-J-74

20*31.85*1 H3.85

CS-J-109

25*40*0.6

CS-J-144

40*30*1 H3.5

CS-J-5

10*20*1.6

CS-J-40

17*22*1

CS-J-75

20*32.1*1 H3.85

CS-J-110

25*110*0.6

CS-J-145

40*56*1

CS-J-6

10*16*6

CS-J-41

17*37.1*1

CS-J-76

20*35*1

CS-J-111

26*30*1 H3.2

CS-J-146

40*43*0.6

CS-J-7

10*10*2

CS-J-42

17*25*1

CS-J-77

21.5*34.5*1.5 H3.5

CS-J-112

26*31*1 H3.5

CS-J-147

40*105*0.635

CS-J-8

10*14*2

CS-J-43

17.8*26*1 H3

CS-J-78

21*28*0.6

CS-J-113

26*35*1

CS-J-148

40*140*0.6

CS-J-9

10.4*18*1 H3.8

CS-J-44

17.8*21.5*1.5 H3.5

CS-J-79

21*28*0.8

CS-J-114

27*60*0.6

CS-J-149

40*150*1

CS-J-10

10.6*17*1 H3.8

CS-J-45

18*19*1.5

CS-J-80

21*28*1

CS-J-115

27*90*0.6

CS-J-150

40*260*1

CS-J-11

11*11*1

CS-J-46

18*23*2 H3

CS-J-81

21.8*30*1 H3

CS-J-116

27*48*1 H5

CS-J-151

44*16*1

CS-J-12

11*17*1

CS-J-47

18*24*0.6

CS-J-82

21.8*30*0.6 H3

CS-J-117

27.5*4.2*2.5

CS-J-152

44*28*0.6 H6

CS-J-13

11*7*1.5

CS-J-48

18*25.3*1.3 H3.2

CS-J-83

21.8*30*1

CS-J-118

28*40*1

CS-J-153

50*50*1

CS-J-14

11*18*1-H4

CS-J-49

18*25.3*1 H3.5

CS-J-84

21.8*30*0.6

CS-J-119

28*42*0.6

CS-J-154

50*50*3

CS-J-15

12*18.5*0.6-H3.8

CS-J-50

18*29*1 H3.5

CS-J-85

22*30*2

CS-J-120

28*44*0.6 H6

CS-J-155

55*18*2

CS-J-16

12*18*0.6-H3.8

CS-J-51

18*29.5*1 H3

CS-J-86

22*28*1 H3.4

CS-J-121

28*64*1

CS-J-156

75*18*2

CS-J-17

12*18.5*1

CS-J-52

18*26*1 H3

CS-J-87

22*28*0.6 H3.4

CS-J-122

28*72*1

CS-J-157

100*100*1

CS-J-18

12*18.5*0.6

CS-J-53

18*26*0.6 H3

CS-J-88

22*28*1

CS-J-123

29*33*1.3

CS-J-158

100*100*2

CS-J-19

12.7*16.5*1.8 H-3.8

CS-J-54

18*26*0.6 H3.5

CS-J-89

22*28*0.6

CS-J-124

30*38*1 H3.5

CS-J-159

100*100*3

CS-J-20

13*19*0.6

CS-J-55

18.5*25*0.6 H3.8

CS-J-90

22*25*1 H3.6

CS-J-125

30*40*1 H3.5

CS-J-160

120*160*2

CS-J-21

14*18*3 H-3.4

CS-J-56

18.5*27*0.6 H3.8

CS-J-91

22*25*0.6 H3.1

CS-J-126

30*43*0.6 H4.5

CS-J-161

120*160*3

CS-J-22

14*19*2 H3.5

CS-J-57

19*23*2 H3.7

CS-J-92

22*25*1 H3.1

CS-J-127

32*50*1

CS-J-162

120*160*4

CS-J-23

14*20*1H3.2/3.5

CS-J-58

20*23*0.6

CS-J-93

22*22*0.6 H3

CS-J-128

32*60*1

CS-J-163

120*160*6

CS-J-24

14*20*0.6H-3.2

CS-J-59

20*26*1 H3.3

CS-J-94

22*35*1

CS-J-129

33*53*1.3

CS-J-164

160*160*1

CS-J-25

14*20*1

CS-J-60

20*2*1 H4

CS-J-95

22*35*1.5 H3.5

CS-J-130

33*73*1.3

CS-J-165

160*160*0.6

CS-J-26

14*20*0.6

CS-J-61

20*26*1

CS-J-96

23*34*1 H3.2

CS-J-131

33.6*51.4*0.8 H5

CS-J-166

D50*2-circle

CS-J-27

14*20*2

CS-J-62

20*26*0.6

CS-J-97

24*30*1

CS-J-132

33.6*51.4*2 H5

CS-J-167

D50*2.5-circle

CS-J-28

14*20*2 H3.2

CS-J-63

20*25*1 H4

CS-J-98

24*35.5*1

CS-J-133

34*64*0.6

CS-J-168

50*3-circle

CS-J-29

15*19.5*1 H3.8

CS-J-64

20*25*0.6 H4

CS-J-99

24*40*0.6

CS-J-134

34*39*0.6

CS-J-30

15*2*2.4

CS-J-65

20*25*1 H3.8

CS-J-100

24*60*1

CS-J-135

35*48*1 H5.5

CS-J-31

16*21*2.5 H3.5

CS-J-66

20*25*0.6 H3.8

CS-J-101

24*70*0.6

CS-J-136

35*68*1

CS-J-32

16*22*0.6 H3.3

CS-J-67

20*25*1 H3.2

CS-J-102

24*72*1

CS-J-137

35*45*1

CS-J-33

16*22*0.6 H4

CS-J-68

20*25*1

CS-J-103

24*90*0.6

CS-J-138

35*85*0.6

CS-J-34

16*22*0.6 H3.7

CS-J-69

20*25*0.6

CS-J-104

24*95*1

CS-J-139

38*38*0.6

CS-J-35

16*46*1

CS-J-70

20*25*2

CS-J-105

24*125*1

CS-J-140

38*50*0.6

OEM/ODM is acceptable. Your goods will be produced exactly according to your drawings or inquiry

1. High-power power semiconductor module;Semiconductor refrigerator and electronic heater;Power control circuit, power hybrid circuit.

2. Intelligent power module;High frequency switching power supply, solid state relay.

3. Automotive electronics, aerospace and military electronic components.

4. Solar panel components;Telecommunication private exchange, receiving system;Laser and other industrial electronics.

5.Alumina Ceramic Substrate for LED Ceramic Suite, Printers,Direct Bonding Copper.

| Technical Characteristic | Unit | 96% Al2O3 | 99% Al2O3 | |

| Physical Characteristics | Bulk density | g/cm3 | 3.6 | 3.9 |

| Heat Resistance | ℃ | 1400 | 1650 | |

| Water absorption | % | 0 | 0 | |

| Mechanical Characteristics | Flexural strength | Mpa | 340 | 360 |

| Hardness Vickers | Gpa | 13.5 | 15.6 | |

| Elastic modulus | Gpa | 320 | 370 | |

| Poisson’s ratio | - | 0.23 | 0.23 | |

| Thermal Characteristics | Linear expansion coefficient | (20℃-500℃) 10-6/℃ | 7.2 | 8 |

| Thermal conductivity | w/(m.k) | 24 | 32 | |

| Specific Heat | *10-3J/(kg*K) | 0.78 | 0.9 | |

| Electrical Characteristics | Dielectric constant (1MHZ) | - | 9.4 | 9.9 |

| Dielectric loss angle | *10-4 | 5 | 1 | |

| Dielectric strength | *106V/m | 15 |

15 |

|

Q1. What information should we supply to get a quote?

Please offer the specification of ceramic substrates, such as shape, dimension, quantity, application etc.

Q2. What types of alumina substrates are available?

Alumina substrates are available in a variety of types, including uncoated, coated, and laser-etched. The type of substrate used will depend on the application and the desired properties.

Q3: What is the difference between alumina substrates and other ceramic substrates?

Alumina substrates have higher electrical insulation than other ceramic substrates, such as beryllium oxide or aluminum nitride. They also have higher thermal conductivity and better mechanical stability than other substrates.

Q4. What is the lead time for the alumina substrates?

The lead time for the alumina substrates is dependent on the size and quantity required. Please contact us for more information.

1. First, wipe the substrate with a damp cloth to remove dust and dirt.

2. Use a soft bristle brush and a mild detergent solution to scrub the substrate.

3. Wash the substrate with clean water, and then dry it with a soft cloth.

4. Ensure that the substrate is dry when used next time.

1. Visual inspection of the substrate for any signs of damage or irregularities.

2. Measurement of the length, width, and thickness of the substrate to check for accuracy.

3. Checking for any pinhole defects in the substrate.

4. Verification of the material and chemical composition of the substrate.

1. We supply personalized and customized services to contact your personal needs.

2. We are experienced professionals with a good record of success.

3. We provide superior client service and promptly respond to all inquiries.

4. We provide militant prices and strive to ensure that your funds receive the best value.

5. We use the latest technologies and tools to ensure that your project is completed to the highest standards.

Aluminum Oxide Metalized Substrate Ceramic Substrate DBC DPC Processed

Aluminum Oxide Metalized Substrate Ceramic Substrate DBC DPC Processed

Alumina ceramic metalized substrates are ceramic copper-clad plates with electrical conductivity, thermal conductivity, and high insulation properties, formed by metalizing alumina ceramic substrates with copper.

Bulletproof Alumina Plate Alumina Plate for Armor

Bulletproof Alumina Plate Alumina Plate for Armor

The bulletproof alumina ceramic plate is made of 99% pure alumina, achieving a Rockwell hardness of over 88. It meets the lining requirements for bulletproof vests rated from Level 3 to Level 6 and can also be utilized in the manufacturing of protective devices for tanks and armored vehicles.

High Temperature Alumina Ceramic Disc/Substrate/Plate

High Temperature Alumina Ceramic Disc/Substrate/Plate

Alumina ceramic disc used in all electric products, electric heating products and wear resistant machinery parts.Small volume, light weight, high strength and space saving.

Customized 96% 99% 99.5% 99.7% Alumina Ceramic Substrate/Plate/Sheet

Customized 96% 99% 99.5% 99.7% Alumina Ceramic Substrate/Plate/Sheet

OEM/ODM is acceptable. Your goods will be produced exactly according to your drawings or inquiry. Alumina Ceramic Substrate are small volume, light weight, high strength and space saving.

Tzero Premium Aluminum light weight lids 901671.901 for TA Instruments Q20/Q2000/Q25/Q2500

Tzero Premium Aluminum light weight lids 901671.901 for TA Instruments Q20/Q2000/Q25/Q2500

TA Tzero Solid sample test Aluminum Sample lids for TA Instruments T Zero Q20/Q200. Manufacturer for TA crucibles and DSC sample pans. TA Instruments good alternative sample cups. TA 901671.901

Tungsten, Coarse Grain 763-263 502-857 Horiba® 1100132389/3 014 011 500//905.110.140.001/905.110.140.001AN

Tungsten, Coarse Grain 763-263 502-857 Horiba® 1100132389/3 014 011 500//905.110.140.001/905.110.140.001AN

763-263 Tungsten Accelerator12-20 Mesh Manufacturer of LECO Eltra Alpha Tungsten Consumables. Eltra 90220 Elementar EXACC WS 750/ EXACC WS 2270W Bruker L030000217 Horiba 3014011500 Alpha AR027.

High Temperature Low-form Ceramic Crucibles with Lids

High Temperature Low-form Ceramic Crucibles with Lids

1. Glazed utensils work satisfactorily at temperatures up to 1050°C. 2. Both of them meet requirements aquired by chemical and physical analysis.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522