Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

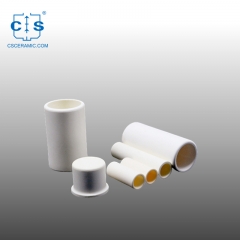

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

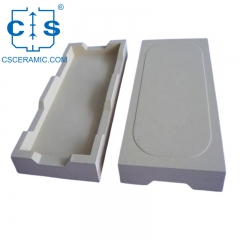

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

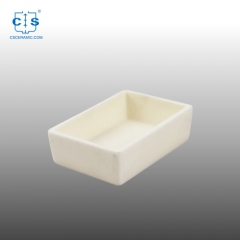

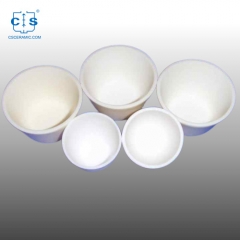

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read MoreZirconia sagger is a type of sintering tray widely used in muffle furnaces, tube furnaces, and tunnel furnaces.

item no. :

CS-YHG-XB043Color :

WhitePort :

Any ports of Chinalead date :

5-7 daysMaterial : Zirconia ceramic

Purity : 98.5%

Shape : Round

1.High purity>99.7%

2. Max work temperature 2200 degree

3. High flexural strength

4. Very high fracture toughness

5. Good wear resistance

6. Low thermal conductivity

7. Good resistance to thermal shocks

8. Resistance to chemical reactions

9. Electrical conductivity at high temperature

Zirconia Saggar's Description

Zirconia saggers are special refractory and heat-resistant materials used to protect and contain the fired product. Due to their high compactness, high temperature resistance, oxidation resistance, and long service life, they are often used as containers for loading materials during high-temperature sintering processes, and are important basic tools in the ceramic industry, refractory industry, abrasive industry, and battery material industry.

Sintering Tray's Technical Parameters

|

Item |

Unit |

Zirconia (ZrO2) |

|

Bulk density |

g/cm3 |

6.05 |

|

Water absorption |

% |

0 |

|

Flexural strength |

MPa |

1000 |

|

Hardness vickers |

GPa |

89 |

|

Elastic modulus |

Gpa |

200 |

|

Linear expansion coefficient |

10-6/℃ (20~500℃) |

10 |

|

Thermal conductivity |

w/m.K |

2.5 |

|

Dielectric strength |

106V/m |

N/A |

| Item No. | Volume(ml) |

Outer diameter

(mm)

|

Inner diameter

(mm)

|

Height(mm) | Purity |

| CS-YHG-XB043 | 51 | 70 | 60 | 24 | 95-98.5% |

| CS-YHG-XB044 | 127 | 50 | 40 | 106 | 95-98.5% |

| CS-YHG-XB045 | 142 | 50 | 40 | 118 | 95-98.5% |

| CS-YHG-XB046 | 169 | 100 | 87 | 35 | 95-98.5% |

| CS-YHG-XB047 | 210 | 78 | 57 | 89 | 95-98.5% |

| CS-YHG-XB048 | 215 | 69 | 50 | 118 | 95-98.5% |

| CS-YHG-XB049 | 243 | 73 | 50 | 135 | 95-98.5% |

| CS-YHG-XB050 | 362 | 80 | 59 | 143 | 95-98.5% |

| CS-YHG-XB051 | 373 | 70 | 50 | 200 | 95-98.5% |

| CS-YHG-XB052 | 459 | 85 | 75 | 109 | 95-98.5% |

| CS-YHG-XB053 | 566 | 86 | 69 | 160 | 95-98.5% |

| CS-YHG-XB054 | 583 | 87 | 69 | 165 | 95-98.5% |

| CS-YHG-XB055 | 610 | 107 | 82 | 128 | 95-98.5% |

| CS-YHG-XB056 | 1206 | 180 | 160 | 70 | 95-98.5% |

| CS-YHG-XB057 | 2155 | 200 | 170 | 110 | 95-98.5% |

| CS-YHG-XB058 | 3188 | 305 | 285 | 60 | 95-98.5% |

| CS-YHG-XB059 | 6330 | 260 | 240 | 150 | 95-98.5% |

Carefully packed by wooden boxes with padded foams

1. Can not use gasoline spray gun, acetylene gun, alcohol torch direct heating;

2. The crucible for the first time before use, please put in the oven about 105 degrees to bake for 120 minutes out of the water;

3. Heating/cooling speed should not be too fast, below 1200℃ < 5℃/min; Above 1200℃ < 4℃/min;

4. Cooling is recommended to power control cooling, high temperature power off with the furnace cooling speed is too fast in the early stage, may lead to cracking.

OEM Requirements

We are able to customize Zirconia Sintering Dental Saggar according to your specific requirements.

1.We can tailor the dimensions, the material, the shape, the design, the colors, etc. to suit your project needs.

2.We also have the capability to develop and produce custom molds and fixtures that can be used to create unique designs.

3.Our team can provide technical support and guidance to ensure that the product meets your desired specifications.

As a professional industrial ceramic supplier, we have a series of advantages that guarantee our market share in the international trade market.

1.Reliable quality control, complete specifications, support customization of non-standard products;

2.Professional and committed service team;

3.Multiple protection of packaging, secure and reliable;

4.Highly efficient delivery channel, safe and rest-assured.

FAQ

1.Q: What is zirconia sintering dental saggar?

A:Zirconia sintering dental saggars are used in the dental industry to increase the durability of dental prosthetics. They are made of a material called Zirconia and are heated in an oven to create a strong bond between the teeth and the prosthetic. This process is known as sintering.

2.Q:What are the benefits of using zirconia sintering dental saggars?

A:Zirconia sintering dental saggars are strong and durable, making them ideal for dental prosthetics. They also provide a better fit for the prosthetic, as well as a more natural looking appearance. Additionally, zirconia sintering dental saggars are less likely to corrode or degrade over time, making them a great long-term investment.

3.Q:How long does zirconia sintering dental saggar last?

A: The longevity of zirconia sintering dental saggars depends on the quality of the material used and the care taken during the sintering process.

Related Products

Square Zirconia Smelting Crucible Cylinder Zirconia ceramic refractory crucibles

Cylinder Zirconia ceramic refractory crucibles

Cylinder Zirconia ceramic refractory crucibles

Zirconia crucibles with a purity of 99%, a density of 5.5~6.0g/cm3 and a maximum working temperature of 2200°C are mainly used in the melting of precious metals.

High-Temp Zirconia Ceramic Tray Acid Alkali Resistant Crucible

High-Temp Zirconia Ceramic Tray Acid Alkali Resistant Crucible

High-Efficiency Zirconia Ceramic Tray, designed with a dish-like shape featuring a large base and low height, available in both circular and square configurations to suit your needs. These trays are renowned for their exceptional high-temperature resistance, acid-alkali corrosion resistance, and superior strength, making them ideal for use in high-1

Square Zirconia Smelting Crucible

Square Zirconia Smelting Crucible

ZrO2 crucible's extreme heat resistance and excellent thermal shock resistance make it ideal for performing high-temperature processes such as melting and annealing metals, as well as for storing, mixing, and heating hazardous materials.

Arc-shaped Zirconia Metal Melting Crucible

Arc-shaped Zirconia Metal Melting Crucible

Zirconia crucibles are specifically designed for melting superalloys and precious metals.Crucibles made of zirconia can provide cleaner melts when heated up to max. temperatures of 2200°C.

High Temp MgO Ceramic Board for Electronics & Industry

High Temp MgO Ceramic Board for Electronics & Industry

MgO plates, resistant to high temp up to 2000°C, are used as insulation boards, heat-resistant gaskets, and burning boards in electronics & industry.

Zirconia plunger / Pump components

Zirconia plunger / Pump components

Zirconia plungers are made of exteme hard zirconia ceramic (zirconia ceramic), have the characteristics of high strength, wear resistance, corrosion resistance, and good toughness, making them more durable than metal coated plungers.

Fused Silica Crucible Quartz Ceramic Crucibles for Melting Gold

Fused Silica Crucible Quartz Ceramic Crucibles for Melting Gold

Fused quartz ceramic crucibles are mainly used for the melting of platinum, gold,and other high-temperature alloys,with high purity,corrosion resistance, and strong thermal shock resistance. Available in various shapes and sizes.

Alumina Silicate Filter Box for Aluminum Casting Filtration

Alumina Silicate Filter Box for Aluminum Casting Filtration

The alumina silicate filter box ensures stable filtration for aluminum melts, withstanding thermal shock, mechanical stress, and featuring low thermal conductivity.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522