Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

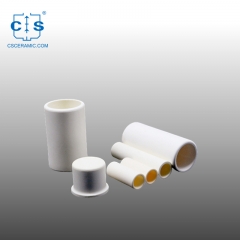

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

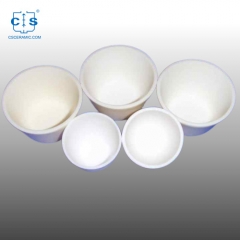

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read Moreitem no. :

CS-YHG-XB001Material : ZrO2

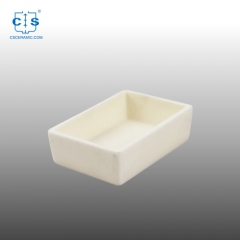

Exceptional High-Temperature Resistance: With a maximum operating temperature exceeding 1400°C, zirconia ceramic trays stand up to the harshest thermal conditions, ensuring reliability in high-temperature applications.

Outstanding Thermal Stability: Maintaining stable physical and chemical properties even under extreme heat, these trays demonstrate unmatched thermal stability, crucial for consistent performance in demanding environments.

Superior Heat Retention: Designed with excellent heat retention properties, zirconia trays ensure uniform heating of samples, promoting consistent results in calcination and sintering processes.

Chemical Resistance & Corrosion Durability: Chemically stable and corrosion-resistant, zirconia trays withstand the erosion of various chemicals, making them ideal for a wide range of material processing applications.

Versatile Applications: Zirconia ceramic trays are widely utilized across various industries, including ceramics, chemicals, metallurgy, electronics, materials science, and lithium batteries.

Perfect for Material Holding: They are perfect for holding calcined materials or ceramic green bodies, providing a stable and reliable platform for these materials.

Durability and Performance: The durability and performance of zirconia ceramic trays make them ideal for placement in furnaces for calcination or sintering.

High-Quality Results: By using zirconia ceramic trays, high-quality results can be ensured in various material processing tasks, thanks to their exceptional properties.

Zirconia Ceramic Tray

Item no.

Length

(mm)

Width

(mm)

Height

(mm)

Thickness

(mm)

ZrO2's Purity

(%)

Volume

(ml)

Remarks

CS-YHG-XB001

100

100

12

5

92-95

56

Flat

CS-YHG-XB002

100

100

13

5

92-95

64

Grooved

CS-YHG-XB003

100

100

15

5

92-95

80

Grooved

CS-YHG-XB004

100

100

20

5

92-95

120

Grooved

CS-YHG-XB005

100

81

28

5

92-95

64

Grooved

CS-YHG-XB006

100

100

13

5

92-95

59

Grooved

CS-YHG-XB007

100

100

15

6

92-95

22

Grooved

CS-YHG-XB008

115

60

9

6

92-95

60

Grooved

CS-YHG-XB009

115

60

7

6

92-95

58

Grooved

CS-YHG-XB010

120

120

40

6.5

92-95

297

Grooved

CS-YHG-XB011

127

127

21

5

92-95

161

Grooved

CS-YHG-XB012

128

128

25

5

92-95

270

Grooved

CS-YHG-XB013

135

135

35

9

92-95

355

Grooved

CS-YHG-XB014

145

145

55

11

92-95

575

Grooved

CS-YHG-XB015

150

150

18

10

92-95

49

Grooved

CS-YHG-XB016

150

150

50

10

92-95

507

Flat

CS-YHG-XB017

155

155

28

10

92-95

300

Grooved

CS-YHG-XB018

200

100

30

8.5

92-95

350

Flat

CS-YHG-XB019

200

105

30

10

92-95

350

Grooved

CS-YHG-XB020

220

180

80

14

92-95

1634

Grooved

CS-YHG-XB021

230

230

45

12

92-95

1400

Grooved

CS-YHG-XB022

230

300

50

12

92-95

1752

Grooved

CS-YHG-XB023

230

165

60

12

92-95

1080

Grooved

CS-YHG-XB024

248

155

62

13

92-95

1467

Grooved

CS-YHG-XB025

250

250

100

10

92-95

3000

Grooved

CS-YHG-XB026

295

195

55

10

92-95

1137

Grooved

CS-YHG-XB027

300

300

175

12

92-95

6000

Flat

CS-YHG-XB028

300

300

110

12

92-95

5400

Flat

CS-YHG-XB029

300

300

150

12.5

92-95

8000

Flat

CS-YHG-XB030

315

158

83

13

92-95

2565

Grooved

CS-YHG-XB031

320

320

110

14

92-95

7500

Grooved

CS-YHG-XB032

320

320

60

14

92-95

3900

Grooved

CS-YHG-XB033

320

320

75

15

92-95

5000

Grooved

CS-YHG-XB034

320

320

48

14

92-95

2800

Flat

CS-YHG-XB035

320

320

80

15

92-95

5000

Grooved

CS-YHG-XB036

320

320

85.5

14

92-95

6000

Grooved

CS-YHG-XB037

320

320

100

15

92-95

7000

Grooved

CS-YHG-XB038

320

320

85

15

92-95

5186

Grooved

CS-YHG-XB039

330

330

100

13

92-95

8000

Grooved

CS-YHG-XB040

330

330

100

12

92-95

8200

Grooved

Cylinder Zirconia ceramic refractory crucibles

Cylinder Zirconia ceramic refractory crucibles

Zirconia crucibles with a purity of 99%, a density of 5.5~6.0g/cm3 and a maximum working temperature of 2200°C are mainly used in the melting of precious metals.

Round Zirconia Sintering Dental Saggar with Lid

Round Zirconia Sintering Dental Saggar with Lid

Zirconia sagger is a type of sintering tray widely used in muffle furnaces, tube furnaces, and tunnel furnaces.

Square Zirconia Smelting Crucible

Square Zirconia Smelting Crucible

ZrO2 crucible's extreme heat resistance and excellent thermal shock resistance make it ideal for performing high-temperature processes such as melting and annealing metals, as well as for storing, mixing, and heating hazardous materials.

Arc-shaped Zirconia Metal Melting Crucible

Arc-shaped Zirconia Metal Melting Crucible

Zirconia crucibles are specifically designed for melting superalloys and precious metals.Crucibles made of zirconia can provide cleaner melts when heated up to max. temperatures of 2200°C.

30µL Vented Autosampler Aluminum Sample Pans equivalent to PE B0143018

30µL Vented Autosampler Aluminum Sample Pans equivalent to PE B0143018

for PerKinElmer DSC and TGA measurements. Manufacturer for PerkinElmer crucibles and sample pans.

Full Cone Silicon Carbide Spray Nozzle

Full Cone Silicon Carbide Spray Nozzle

SiC spray nozzle full cone is a nice choice as a key component for desulfurization and dust removal in thermal power plants, due to its high hardness, erosion resistance, corrosion resistance, and oxidation resistance.

Slip-on plates made of Al2O3,for sample and reference position equivalent to Netzsch JA004734 and JA004735 for STA 2500 Regulus

Slip-on plates made of Al2O3,for sample and reference position equivalent to Netzsch JA004734 and JA004735 for STA 2500 Regulus

Manufacturer for Netzsch crucibles and sample cups. Netzsch Instruments good alternative DSC sample pans.

100 uL Aluminum Pans equivalent to TA 952323.902 for TA TGA Q5000 SA

100 uL Aluminum Pans equivalent to TA 952323.902 for TA TGA Q5000 SA

TA 952323.902 Aluminum Sample Pans and lids for TA Instruments .Manufacturer for TA dsc analyzer crucibles and DSC sample pans .TA Instruments good alternative sample cups . TA 901683.901/901684.901

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522