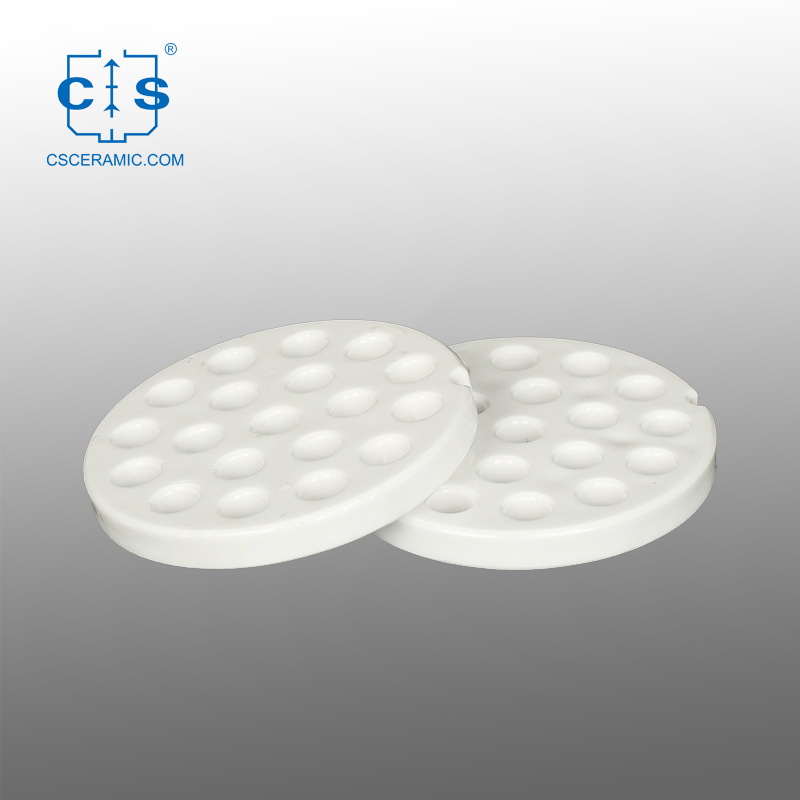

Are you ready to be part of a company with nearly 50 years of expertise in producing specialized ceramic crucibles for carbon and sulfur analyzers? Look no further! CSCERAMIC, established in 1974, stands as a trusted manufacturer of ceramic crucibles, designated by Bruker, a leading name in the industry. We have been instrumental in setting the standards for carbon and sulfur analysis crucibles in China, making us an influential player in the sector. Job Title Distributor Agent (in Russia) About Us At CSCERAMIC, we take pride in our dedication to precision and innovation. Our research and development department crafted the Chinese metallurgical industry standard (YB/T 4145-2006) for specialized carbon and sulfur analysis crucibles, shaping the industry landscape since its implementation in 2006. We believe in fostering strong relationships with our partners, and as a distributor agent, you'll be at the forefront of promoting our essential ceramic crucibles for carbon and sulfur analyzers. Responsibilities As a distributor agent in Russia, you will play a pivotal role in expanding our market presence by: Promoting and introducing our specialized ceramic crucibles to enterprises and research institutions utilizing carbon and sulfur analyzers. Identifying and establishing contacts with local businesses and research institutions in need of carbon and sulfur analysis for research and testing purposes. Facilitating the ordering process and ensuring customer satisfaction with our products and services. Why Join Us We understand the importance of strong partnerships, and as our distributor agent, you'll enjoy an array of benefits and support, including: Lucrative commission-based compensation package for successful sales and partnerships. Extensive product training and marketing materials to facilitate your promotional efforts. Flexible work arrangements, allowing you to manage your schedule efficiently. Dedicated support from our team to address any queries and concerns promptly. Requirements To excel in this role, we are looking for individuals who possess: Strong sales and networking skills, with a proven track record in B2B sales or distribution. Familiarity with the scientific instruments or laboratory equipment market. Excellent communication and negotiation skills to establish and maintain fruitful partnerships. A passion for driving results and a desire to make a significant impact in the industry. Join us in shaping the future of carbon and sulfur analysis! Be a part of CSCERAMIC's journey to provide cutting-edge solutions to researchers and industries across Russia. How to Apply If you are excited to embark on this remarkable opportunity and become our valued distributor agent in Russia, send us your updated resume and a compelling cover letter outlining your relevant experience and why you're the perfect fit for CSCERAMIC. Let's work together to achieve new heights! (please fill the form 'Application Form - CSCERAMIC Distributor Agent Opportunity'.) Contact Information For any inquiries or to submit your application, please reach out to us at E-mail: info@csceramic.com, or Phone Number: +86 15377338375. To learn more about our company and the impact of our ceramic crucibles, visit our website at www.csceramic.com. We eagerly await your application to build a prosperous future together!

info@csceramic.com

info@csceramic.com

+86 18273288522

+86 18273288522