Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

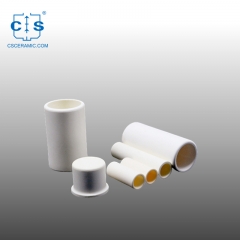

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

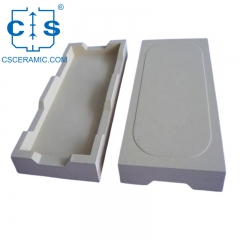

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read MoreZirconia crucibles are specifically designed for melting superalloys and precious metals.Crucibles made of zirconia can provide cleaner melts when heated up to max. temperatures of 2200°C.

item no. :

CS-YHG-H001Color :

WhitePort :

Any ports of Chinalead date :

1-7 daysMaterial : Zirconia

Purity : 95%

Shape : Arch

1. High Temperature Resistance (up to 2200°C ~ 2400°C)

2. High density (up to 6.0g/cm3)

3. Low thermal conductivity

4. Chemical inertness

5. Resistance to molten metals

6. Ionic electrical conduction

7. Wear resistance

8. High fracture toughness

9. High hardness

1.Zirconia crucibles are specialized pieces of laboratory equipment used for metallic element melting and annealing.

2.They are made from zirconia, a strong and corrosion-resistant ceramic stuff capable of withstanding temperatures up to 2,200°C (3,992°F).

3.Zirconia crucibles provide excellent thermal shock resistance, making them ideal for use in metallic element melting and tempering processes.

4.They also provide excellent chemical substance inertness, making them a rubber choice for working with hazardous or undefined materials. With their unique properties.

5. zirconia crucibles are a versatile and reliable tool for a variety of unusual applications, from metalworking to chemical substance processing.

(1) Chemical/metallurgic processes

(2) Laboratory thermal analysis

CS-YHG-H001

27

14

22

1.5

95

5

CS-YHG-H002

25

15

28

1.3

95

5

CS-YHG-H003

29

18

34

1.5

95

10

CS-YHG-H004

32

23

33

1.5

95

15

CS-YHG-H005

36

23

41

1.7

95

20

CS-YHG-H006

36

25

42

1.7

95

25

CS-YHG-H007

38

25

45

1.7

95

30

CS-YHG-H008

38

25

45

2.7

95

30

CS-YHG-H009

45

30

46

2

95

40

CS-YHG-H010

48

30

52

2

95

50

CS-YHG-H011

49

30

54

2.7

95

50

CS-YHG-H012

36

20

42

3

95

60

CS-YHG-H013

57

30

45

3

95

60

CS-YHG-H014

58

33

66

2

95

70

CS-YHG-H015

59

45

52

2.5

95

80

CS-YHG-H016

62

34

50

3

95

80

CS-YHG-H017

58

35

68

2

95

100

CS-YHG-H018

59

35

71

2.8

95

100

CS-YHG-H019

67

42

78

2.5

95

150

CS-YHG-H020

73

44

86

2.5

95

200

CS-YHG-H021

79

46

96

2.5

95

250

CS-YHG-H022

75

46

78

3.5

95

250

CS-YHG-H023

82

58

80

4.2

95

300

CS-YHG-H024

83

50

106

2.5

95

300

CS-YHG-H025

100

60

70

4

95

375

CS-YHG-H026

80

70

115

4.8

95

400

CS-YHG-H027

91

56

108

2.5

95

400

CS-YHG-H028

100

65

110

5.5

95

500

CS-YHG-H029

100

60

118

3

95

500

Item

Outer diameter(mm)

Inner diameter(mm)

Height(mm)

Wall thickness(mm)

Purity(%)

Volume(ml)

Technical Parameters

(1) Constitution of ZrO2 crucible

|

Component |

Percentage |

|

Fe2O3 |

<=0.5 |

|

SiO2 |

<=0.5 |

|

ZrO2 |

>=92 |

|

porosity |

<=0.5 |

(2) Maximum size tolerance allowed for ZrO2 crucible (SB17-88)

|

model size |

unit |

limit |

diameter |

height |

deformation |

|

50 |

mm |

<= |

±1 |

±2 |

2% |

|

50~100 |

mm |

<= |

±1.5 |

±2.5 |

3% |

|

100 |

mm |

<= |

±1.5 |

±2.5 |

3.5% |

Zirconia Crucible test standard

1. visible Test: The crucible should be visually inspected for signs of cracks, chips, or other signs of damage.

2. angle Test: The crucible should be weighed to insure that it meets the stated weight requirements.

3. thermic Shock Test: The crucible should be subjected to thermic shock testing to ensure that it can withstand fulminant changes in temperature without cracking or deforming.

4. energy Expansion Test: The crucible should be heated to a temperature above the thaw direct of the material and then cooled to control that it can withstand thermal stresses.

5. Impact Test: The crucible should be dropped from a predetermined tallness to verify that it can resist physical science impacts.

6. Corrosion underground Test: The crucible should be exposed to different undefined agents to insure that it is resistant to corrosion.

7. flex Test: The crucible should be bent to control that it is strong enough to withstand physics forces.

Carefully packed by wooden boxes with padded foams.

Use/Maintenance Methods

1.Do not use gasoline spraying gun, acetylene gun or alcohol burner for direct heating.

Zirconia Ceramic crucible OEM requests

1.We can customize the crucibles based on the customer's specifications, such as size, shape, type, etc.

2.Additionally, we can provide custom branding on the crucibles, as well as color customization.

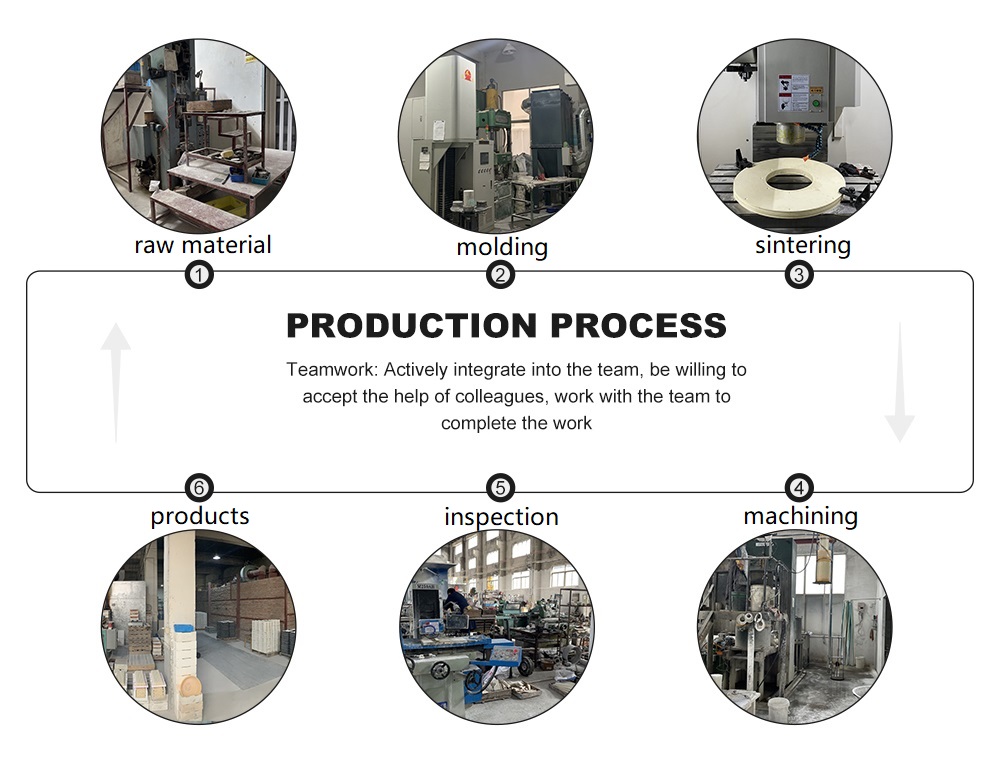

As a professional industrial ceramic supplier, we have a series of advantages that guarantee our market share in the international trade market.

1.Reliable quality control, complete specifications, support customization of non-standard products

FAQ

1.Q: What is an arc-shaped zirconia metal crucible?

A: An arc-shaped zirconia metal crucible is a type of high-temperature crucible which is made from zirconia-toughened alumina (ZTA) ceramic material. It is designed with a curved surface that allows for efficient heat transfer and an even distribution of temperature during the crucible melting process. This type of crucible is typically used in the scientific research, metallurgical, and chemical industries.

2.Q:What's the delivery time?

A: 1-7 working days for standard products 20-30 days for customized products.

3. Q:What is the maximum temperature that a zirconia ceramic crucible can withstand?

A:The maximum temperature that a zirconia ceramic crucible can withstand is around 2,200°C (4,000°F).

4. Q:Are there any safety precautions that need to be taken when using a zirconia ceramic crucible?

A:Yes, it is important to wear protective gear when using a zirconia ceramic crucible.

Cylinder Zirconia ceramic refractory crucibles

Cylinder Zirconia ceramic refractory crucibles

Zirconia crucibles with a purity of 99%, a density of 5.5~6.0g/cm3 and a maximum working temperature of 2200°C are mainly used in the melting of precious metals.

Round Zirconia Sintering Dental Saggar with Lid

Round Zirconia Sintering Dental Saggar with Lid

Zirconia sagger is a type of sintering tray widely used in muffle furnaces, tube furnaces, and tunnel furnaces.

High-Temp Zirconia Ceramic Tray Acid Alkali Resistant Crucible

High-Temp Zirconia Ceramic Tray Acid Alkali Resistant Crucible

High-Efficiency Zirconia Ceramic Tray, designed with a dish-like shape featuring a large base and low height, available in both circular and square configurations to suit your needs. These trays are renowned for their exceptional high-temperature resistance, acid-alkali corrosion resistance, and superior strength, making them ideal for use in high-1

Square Zirconia Smelting Crucible

Square Zirconia Smelting Crucible

ZrO2 crucible's extreme heat resistance and excellent thermal shock resistance make it ideal for performing high-temperature processes such as melting and annealing metals, as well as for storing, mixing, and heating hazardous materials.

80 uL Aluminum Lids equivalent to TA 957362.901 for TA Q5000 IR

80 uL Aluminum Lids equivalent to TA 957362.901 for TA Q5000 IR

TA 957362.901 Aluminum Sample covers and lids for TA Instruments .Manufacturer for TA dsc analyzer crucibles and DSC sample pans .TA Instruments good alternative sample cups .

150µl Sapphire crucible with lid same size as ME-00024124 for Mettler toledo

150µl Sapphire crucible with lid same size as ME-00024124 for Mettler toledo

Sapphire crucible /sampple pan for Mettler toledo Thermal analysis. Manufacturer for Mettler Toledo crucibles and sample pans. More THERMAL ANALYSIS CONSUMABLES, DSC crucibles are supplied.

Quartz Probes Expansion Probe Thermomechanical Analyzer Probes For TA TMA Q400/TMA 450

Quartz Probes Expansion Probe Thermomechanical Analyzer Probes For TA TMA Q400/TMA 450

Quartz Probes For TA TMA Q400/TMA 450.They are designed to be used in expansion,penetration,flexural and tension modes of deformation and are used to determine coefficient of thermal expansion,shrinkage,softening points,sintering temperatures, elongation and much more.

Alumina Ceramic Tubes/Pipes Both Open Single Bore Tubes Length 1mm-2500mm

Alumina Ceramic Tubes/Pipes Both Open Single Bore Tubes Length 1mm-2500mm

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522