Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

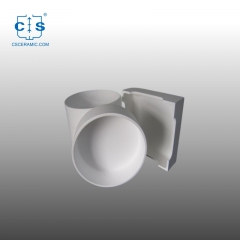

Read MoreFused quartz ceramic crucibles are mainly used for the melting of platinum, gold,and other high-temperature alloys,with high purity,corrosion resistance, and strong thermal shock resistance. Available in various shapes and sizes.

item no. :

CS-QC-A001Material : SiO₂ Quartz Ceramic

Purity Available : 99%

Shape : Various shapes; customized

1. High temperature resistance: Fused quartz ceramic crucibles can withstand extremely high temperatures, making them ideal for use in applications that require intense heat, such as melting metals or performing experiments at high temperatures.

2. Chemical inertness: Quartz is highly resistant to chemical reactions, making fused quartz ceramic crucibles suitable for use with a wide range of chemicals and substances. They do not interact with the materials being processed or react to the substances present, ensuring purity and accuracy in experiments or manufacturing processes.

3. Thermal shock resistance: They have excellent thermal shock resistance, this property makes them highly reliable and durable for repeated heating and cooling cycles.

4. Low thermal expansion: The low coefficient of thermal expansion of fused quartz ceramic crucibles ensures minimal dimensional changes when exposed to temperature variations. This property allows for precise and consistent measurements and reduces the risk of thermal stresses in the crucibles.

5. Long lifespan: Due to their excellent chemical resistance, high-temperature capability, and durability, fused quartz ceramic crucibles have a long lifespan. They can withstand multiple uses and can be repeatedly cleaned or sterilized without significant degradation, making them a cost-effective choice for various applications.

1. Fused quartz ceramic crucibles are premium-quality, heat-resistant containers ideal for high-temperature applications in scientific laboratories and industrial settings.

2. Crafted from quartz ceramic, these crucibles offer outstanding resistance to thermal shock, making them perfect for various heating and melting processes. Their excellent thermal insulation properties ensure uniform heat distribution and prevent contamination of the sample, guaranteeing accurate and reliable results.

3. Designed with a smooth interior surface, these fused quartz ceramic crucibles facilitate easy pouring and retrieval of materials, enhancing efficiency and reducing the risk of spillage or waste. Their non-porous nature ensures minimal adsorption or absorption of substances, ensuring accurate sample analysis and minimizing cross-contamination.

4. Ideal for use in high-temperature applications, these fused quartz ceramic crucibles offer exceptional resistance to thermal fatigue and mechanical stress. They can withstand prolonged exposure to extreme temperatures without experiencing significant deformation or structural damage, ensuring optimum reliability and longevity.

Item No.

Height(mm)

Purity

CS-QC-A001

62

46

59

99

91

99%

CS-QC-A002

86

59

74

118

105

99%

CS-QC-A003

88

64

80

126

114

99%

CS-QC-A004

90

64

86

149

136

99%

inquiry.

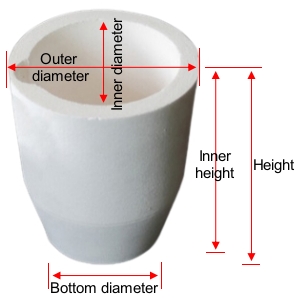

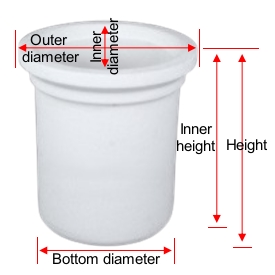

| Item No. |

Outer diameter

(mm)

|

Inner diameter

(mm)

|

Bottom diameter

(mm)

|

Height(mm) |

Inner height

(mm)

|

Purity |

| CS-QC-A007 | 62 | 46 | 59 | 99 | 91 | 99% |

| CS-QC-A008 | 86 | 59 | 74 | 118 | 105 | 99% |

| CS-QC-A009 | 88 | 64 | 80 | 126 | 114 | 99% |

| CS-QC-A010 | 90 | 64 | 86 | 149 | 136 | 99% |

| CS-QC-A011 | 93 | 74 | 62 | 105 | 96 | 99% |

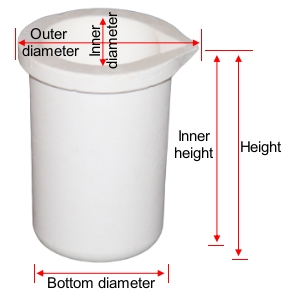

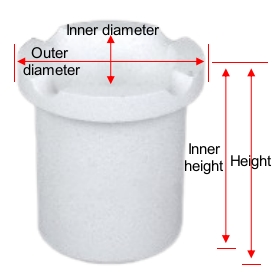

| Item No. |

Outer diameter

(mm)

|

Inner diameter

(mm)

|

Height(mm) |

Inner height

(mm)

|

Purity |

| CS-QC-A012 | 48 | 37 | 55.5 | 50 | 99% |

OEM/ODM is acceptable. Your goods will be produced exactly according to your drawings or inquiry.

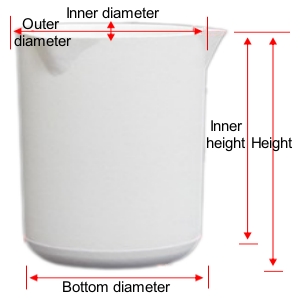

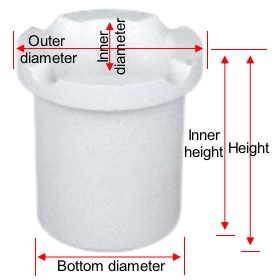

| Item No. |

Outer diameter

(mm)

|

Inner diameter

(mm)

|

Height(mm) |

Inner height

(mm)

|

Purity |

| CS-QC-A013 | 63 | 47 | 70 | 60 | 99% |

| CS-QC-A014 | 60 | 47 | 70 | 63 | 99% |

| CS-QC-A015 | 73 | 56 | 83 | 70 | 99% |

| CS-QC-A016 | 81 | 64 | 94 | 83 | 99% |

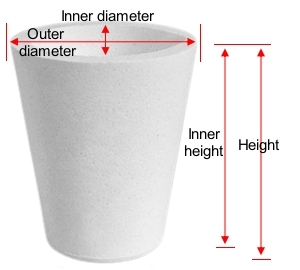

| Item No. |

Outer diameter

(mm)

|

Inner diameter

(mm)

|

Height(mm) |

Inner height

(mm)

|

Purity |

| CS-QC-A017 | 95 | 75 | 108 | 97 | 99% |

OEM/ODM is acceptable. Your goods will be produced exactly according to your drawings or inquiry.

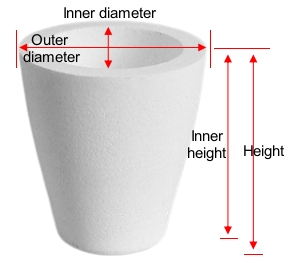

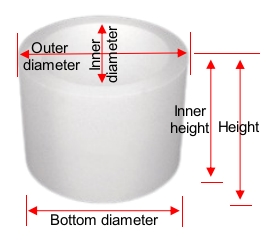

| Item No. |

Outer diameter

(mm)

|

Inner diameter

(mm)

|

Bottom diameter

(mm)

|

Height(mm) |

Inner height

(mm)

|

Purity |

| CS-QC-A018 | 62 | 48 | 62 | 95 | 88 | 99% |

| CS-QC-A019 | 67 | 53 | 67 | 105 | 98 | 99% |

| CS-QC-A020 | 72 | 58 | 72 | 115 | 108 | 99% |

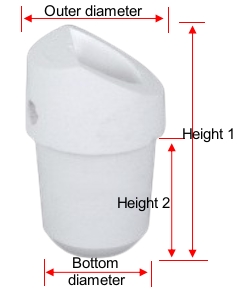

| Item No. |

Outer diameter

(mm)

|

Bottom diameter

(mm)

|

Height 1 (mm) |

Height 2 (mm)

|

Purity |

| CS-QC-A021 | 72 | 61.5 | 124 | 79 | 99% |

OEM/ODM is acceptable. Your goods will be produced exactly according to your drawings or inquiry.

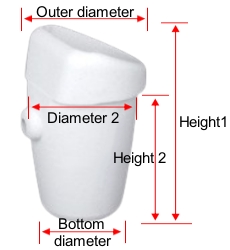

| Item No. |

Outer diameter

(mm)

|

Diameter 2

(mm)

|

Bottom diameter

(mm)

|

Height 1 (mm) |

Height 2 (mm)

|

Purity |

| CS-QC-A022 | 58 | 48 | 44 | 87 | 82 | 99% |

| Item No. |

Outer diameter

(mm)

|

Bottom diameter

(mm)

|

Height 1 (mm) |

Height 2 (mm)

|

Purity |

| CS-QC-A023 | 44 | 40 | 83 | 41 | 99% |

| Item No. |

Outer diameter

(mm)

|

Inner diameter

(mm)

|

Bottom diameter

(mm)

|

Height(mm) |

Inner height

(mm)

|

Purity |

| CS-QC-A024 | 85 | 72 | 85 | 111 | 101 | 99% |

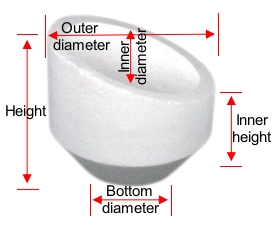

| Item No. |

Outer diameter

(mm)

|

Inner diameter

(mm)

|

Bottom diameter

(mm)

|

Height(mm) |

Inner height

(mm)

|

Purity |

| CS-QC-A025 | 87 | 75 | 87 | 64.5 | 50 | 99% |

| Item No. |

Outer diameter

(mm)

|

Inner diameter

(mm)

|

Bottom diameter

(mm)

|

Height(mm) |

Inner height

(mm)

|

Purity |

| CS-QC-A026 | 76 | 61 | 48 | 63 | 21 | 99% |

| Item No. |

Outer diameter

(mm)

|

Inner diameter

(mm)

|

Bottom diameter

(mm)

|

Height(mm) |

Inner height

(mm)

|

Purity |

| CS-QC-A027 | 43 | 35 | 43 | 57 | 49 | 99% |

| Item No. |

Outer diameter

(mm)

|

Inner diameter

(mm)

|

Bottom diameter

(mm)

|

Height(mm) | Purity |

| CS-QC-A028 | 35 | 29 | 29 | 62 | 99% |

| Item No. |

Outer diameter

(mm)

|

Inner diameter

(mm)

|

Height(mm) | Purity |

| CS-QC-A029 | 35 | 29 | 62 | 99% |

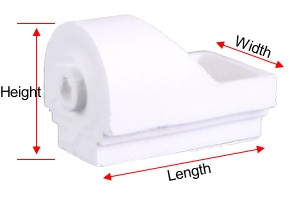

| Item No. | Length (mm) | Width (mm) | Height (mm) | Purity |

| CS-QC-A030 | 67 | 46 | 48 | 99% |

1. Chemical Industry: They are ideal for handling and storing corrosive chemicals due to their excellent resistance to chemical attack. They can be used for mixing, heating, or storing chemicals in laboratories or industrial settings.

2. Metallurgical Industry: They are used in high-temperature applications, such as metal melting and casting. They can withstand extreme temperatures, making them suitable for melting and alloying various metal alloys.

3. Jewelry Manufacturing: They are commonly used in jewelry making for melting precious metals like gold, silver, and platinum. Their high melting points and excellent thermal insulation properties ensure efficient and uniform heating of the metals.

4. Powder Metallurgy: They are employed in powder metallurgy processes, where metal powders are compacted and sintered to create high-performance components. The crucibles provide a controlled environment for the sintering process, ensuring uniform heating and preventing oxidation.

5. Ceramics and Glass Testing: They can be used for testing the properties and behavior of ceramics and glass materials. They provide a controlled environment for firing, annealing, and thermal testing of ceramic and glass samples.

6. Research and Development: They find applications in various research and development projects that require high-temperature and chemically resistant containers. They are commonly used in material synthesis, catalyst preparation, and other experiments requiring controlled heating and mixing.

| Items | Specifications |

| Max Operation Temperature(℃) | 1650 |

| Volume Density(g/cm3) | ≥1.90 |

| Apparent Porosity (%) | ≤15 |

| Room Temperature Compressive Strength(MPa) | ≥50 |

| Room Temperature Flexural Strength (MPa) | ≥20 |

| Thermal Conductivity(W/m·k) (RT~1000℃) | 0.6~1.7 |

| Thermal Expansion Coefficient(℃-1)(RT~1000℃) | ≤0.9×10-6 |

| Crystallinity (vol%) | ≤1 |

Q1. What is a fused quartz ceramic crucible?

A1. A fused quartz ceramic crucible is a specialized container made from high-purity quartz ceramic material. It is designed to withstand high temperatures and harsh chemical environments, making it ideal for various laboratory and industrial applications.

Q2. What are fused quartz ceramic crucibles used for?

A2. Fused quartz ceramic crucibles are commonly used for melting, casting, and holding of various materials. They are often utilized in industries like metallurgy, foundries, and research laboratories.

Q3. Can fused quartz ceramic crucibles be reused?

A3. Yes, fused quartz ceramic crucibles can typically be reused multiple times. However, to ensure optimal performance and prevent contamination, it is important to clean and inspect the crucibles thoroughly before each reuse.

Q4. Are fused quartz ceramic crucibles available in different sizes and shapes?

A4. Yes, fused quartz ceramic crucibles come in various sizes and shapes to accommodate different application requirements. They can be found in standard shapes such as cylindrical, conical, or rectangular, or even customized designs based on specific user needs.

1. Before you clean the quartz ceramic crucible, it is important to make sure that it has cooled completely.

2. Start by brushing off any excess debris with a dry, soft-bristled brush.

3. If the crucible is still dirty, you can use a few drops of mild soap to help loosen any grime and dirt.

4. Gently scrub the surface of the crucible with a soft-bristled brush, rinse the crucible with clean, warm water.

5. Allow the quartz ceramic crucible to air dry.

1. Visual inspection: Carefully examine the crucible visually to identify any visible defects or damage. Look for cracks, chips, or any irregularities on the surface.

2. Measure dimensions: Use a caliper or measuring tape to measure the dimensions of the crucible, including the height, diameter, and wall thickness. Ensure that the measurements are within the specified tolerances.

3. Test for thermal shock resistance: Heat the crucible gradually in a furnace or heating device. Allow it to cool down slowly and observe if any cracks or damage occur.

4. Check for chemical compatibility: Depending on the specific application, verify the chemical compatibility of the fused quartz ceramic crucible with the intended materials or chemicals.

1. We offer personalized and customized services to meet your individual needs.

2. We are experienced professionals with a proven track record of success.

3. We provide excellent customer service and timely responses to all inquiries.

4. We have competitive rates and work to ensure that you get the best value for your money.

5. We use the latest technology and tools to ensure that your project is completed to the highest standards.

6. We take pride in our work and strive for complete customer satisfaction.

Quartz Ceramic Crucibles Bowls Silica Crucibles for Melting Gold

Quartz Ceramic Crucibles Bowls Silica Crucibles for Melting Gold

Quartz ceramic crucibles bowls silica crucibles are cost-effective, reusable, easy to clean, and resistant to high temperatures and chemical corrosion, making them suitable for handling various substances. Available in various sizes and shapes.

SiO2 Quartz Ceramic Crucibles

SiO2 Quartz Ceramic Crucibles

SiO2 Quartz ceramic crucibles are cost-effective, reusable, easy to clean, and resistant to high temperatures and chemical corrosion, making them suitable for handling various substances. Available in various sizes and shapes.

Small Crucible Cover 529-043 Alpha AR9043 for TGA 16cc

Small Crucible Cover 529-043 Alpha AR9043 for TGA 16cc

Small Crucible Cover 529-043 Alpha AR9043 for TGA 16cc. Manufacturer of Ceramic Crucible lid for LECO TGA 500/501/601/701, MAC 400/500.

Alumina Ceramic Sharpener Rod

Alumina Ceramic Sharpener Rod

Ceramic sharpener rod ceramic honing rod shows excellent hardness and wear resistance, which is used to hone the knives and maintain the edge.Available in various sizes and shapes.

Alumina Ceramic Crucible with Nozzle (without cover)

Alumina Ceramic Crucible with Nozzle (without cover)

OEM Alumina Crucibles are laboratory consumables, which shows high heat-resistance. furnace lining ceramic crucible.

0.9ml Highly Sintered Ceramic crucible equivalent to Netzsch NGB820039

0.9ml Highly Sintered Ceramic crucible equivalent to Netzsch NGB820039

CSCERAMIC is source manufacturer of thermal analysis consumables

NIJ IV Level SiC Ceramic Bulletproof Plate for Armor Lining & Protective Shielding

NIJ IV Level SiC Ceramic Bulletproof Plate for Armor Lining & Protective Shielding

The SiC ceramic bulletproof plate boasts high hardness (HV2600+), NIJ IV-level protection, ideal for body armor lining & vehicle, aircraft, & ship armor.

Graphite Crucible 769-761 for For Hydrogen Analysis

Graphite Crucible 769-761 for For Hydrogen Analysis

LECO 769-761Graphite Crucible. Manufacturer of LECO Alpha Graphite Crucible.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522