Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read Moreitem no. :

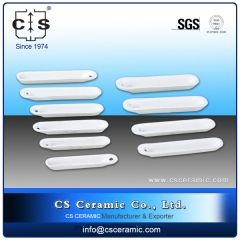

CS-DBC-C001Material : Alumina ceramic

3. Metalized alumina ceramic substrates exhibit excellent thermal conductivity and high current-carrying capacity, enabling compact chip packaging, significantly increasing power density, and improving the reliability of systems and devices.

Applications of Alumina Metalized Substrate

Alumina metalized substratess can be applied in automotive electronics, aerospace, solar panel arrays, communication equipment, laser devices, and other fields.

It serves not only as carrier plates to support components but also function as heat dissipation and insulation materials. Additionally, they enable interlayer circuit interconnection, achieving superior electrical performance. They are widely used in automotive electronics, sensors, power modules, high-frequency switching power supplies, relays, communication modules, LED modules, and other applications.

Size Chart for Alumina Metalized Substrate

| Alumina Metalized Substrate Rectangular | ||||||

| Item NO. | Length (mm) | Width (mm) | Thickness (mm) | Thickness of Copper Foil (mm) | Copper Coating Thickness (mm) | Purity (%) |

| CS-DBC-C001 | 10 | 5 | 0.25 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| CS-DBC-C002 | 18 | 11 | 0.25 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| CS-DBC-C003 | 20 | 15 | 0.38 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| CS-DBC-C004 | 28 | 9 | 0.635 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| CS-DBC-C005 | 32 | 24 | 0.55 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| CS-DBC-C006 | 55 | 30 | 6 | 0.1-0.6 | 0.035 | 96 |

| CS-DBC-C007 | 70 | 52 | 0.76 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| CS-DBC-C008 | 84 | 35 | 1 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| CS-DBC-C009 | 103 | 90 | 0.635 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| CS-DBC-C010 | 127 | 105 | 2 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| CS-DBC-C011 | 156 | 84 | 3 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| CS-DBC-C012 | 178 | 138 | 5 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| CS-DBC-C013 | 188 | 138 | 4.6 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| Alumina Metalized Substrate Square | ||||||

| Item NO. | Length (mm) | Width (mm) | Thickness (mm) | Thickness of Copper Foil (mm) | Copper Coating Thickness (mm) | Purity (%) |

| CS-DBC-Z001 | 10 | 10 | 0.25 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| CS-DBC-Z002 | 15 | 15 | 0.25 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| CS-DBC-Z003 | 18 | 18 | 0.25 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| CS-DBC-Z004 | 25 | 25 | 0.38 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| CS-DBC-Z005 | 31.5 | 31.5 | 0.635 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| CS-DBC-Z006 | 33 | 33 | 0.76 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| CS-DBC-Z007 | 40 | 40 | 0.76 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| CS-DBC-Z008 | 60 | 60 | 1 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| CS-DBC-Z009 | 72 | 72 | 1 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| CS-DBC-Z010 | 100 | 100 | 3 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| CS-DBC-Z011 | 127 | 127 | 1 | 0.1-0.6 | 0.035 | 99.7 |

| CS-DBC-Z012 | 138 | 138 | 5 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

Usage Instructions

1. Metalized alumina ceramic substrates should avoid prolonged exposure to high-temperature environments and contact with organic solvents to prevent performance degradation.

2. Before use, inspect the surface of the substrate for scratches, cracks, or other defects and only use it after confirming its integrity.

3. Ensure proper connection of the metalized alumina ceramic substrate to the power source and correct grounding to prevent electrostatic damage to the substrate.

Dedicated to delivering well-performed metalized alumina substrates customized to your precise needs. Our devoted team guarantees careful adherence to your instructions, aiming to surpass customer expectations. Moreover, we provide the flexibility of tailor-made sizes to meet your unique requirements.

Please provide necessary parameters including the substrate dimension drawing, PCB design drawing (if etching is not required), metal material, number of layers, and thickness.

Alumina Ceramic Substrate Sheet/Plate

Alumina Ceramic Substrate Sheet/Plate

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Bulletproof Alumina Plate Alumina Plate for Armor

Bulletproof Alumina Plate Alumina Plate for Armor

The bulletproof alumina ceramic plate is made of 99% pure alumina, achieving a Rockwell hardness of over 88. It meets the lining requirements for bulletproof vests rated from Level 3 to Level 6 and can also be utilized in the manufacturing of protective devices for tanks and armored vehicles.

High Temperature Alumina Ceramic Disc/Substrate/Plate

High Temperature Alumina Ceramic Disc/Substrate/Plate

Alumina ceramic disc used in all electric products, electric heating products and wear resistant machinery parts.Small volume, light weight, high strength and space saving.

Customized 96% 99% 99.5% 99.7% Alumina Ceramic Substrate/Plate/Sheet

Customized 96% 99% 99.5% 99.7% Alumina Ceramic Substrate/Plate/Sheet

OEM/ODM is acceptable. Your goods will be produced exactly according to your drawings or inquiry. Alumina Ceramic Substrate are small volume, light weight, high strength and space saving.

Alumina Ceramic crucibles S08/11297 for Setaram CTC1800 Evolution (Sample pans)

Alumina Ceramic crucibles S08/11297 for Setaram CTC1800 Evolution (Sample pans)

D5*10MM Setaram 160ul Alumina crucible/cell/cup for Setaram CTC1800 Evolution DSC and TGA measurements. Manufacturer for Setaram crucibles and sample pans. Thermal Analyzers sample pan for tga thermal analysis.

100μl Aluminum crucibles standard w/lid ME-51119872/ME-51119871 for Mettler toledo (Sample pans)

100μl Aluminum crucibles standard w/lid ME-51119872/ME-51119871 for Mettler toledo (Sample pans)

ME-51119872/ME-5111987 Aluminum crucibles sample pans for Mettler DSC and TGA measurements. Thermal analysis crucibles for dsc instrument. Manufacturer for Mettler Toledo crucibles and sample pans.

77mm Ceramic Boat for Tube Furnace

77mm Ceramic Boat for Tube Furnace

1. Scientific tools used in experiments because of their resistance to heat and caustic chemicals. 2. Porcelain. Glazed inside and out, except for outside bottom surface. Max. use temp.: 1,150 °C.

Ampoules for TGA and TGA-DTA measurements equivalent to Netzsch GB461177

Ampoules for TGA and TGA-DTA measurements equivalent to Netzsch GB461177

GB461177 Netzsch Fused silica parts .csceramic provides all thermal analysis consumables

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522