Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read Moreitem no. :

CS-AM1-00199.5% 99.7% 99% 90% 92% 95%

Material : Alumina ceramic

Shape : OEM

1. High Hardness: Alumina ceramic parts are known for their high hardness, making them ideal for use in high-wear applications.

2. Electrical Insulation: They provide excellent electrical insulation, making them ideal for use in electronic components and insulators.

3. Low Thermal Expansion: They have a low thermal expansion coefficient, meaning they do not expand or contract much with changes in temperature. This makes them ideal for use in applications where dimensional stability is critical.

4. Wear Resistance: They are highly wear-resistant and can withstand abrasive wear without deteriorating or losing their shape.

5. Good Machinability: Alumina ceramic is easy to machine, allowing for precise tolerances and complex shapes to be achieved.

6. Cost-Effective: They offer excellent performance at a relatively low cost compared to other high-performance materials such as metals or composites.

7. Environmental Stability: They are stable in a variety of environmental conditions, including exposure to UV radiation, humidity, and atmospheric pollution.

1. Alumina ceramic parts are made from a material called alumina, they are typically used in industrial applications.

2. Some common alumina ceramic parts include ball bearings, insulators, and seals. Ball bearings made from alumina ceramic are used in high-speed machinery, while insulators and seals are used in electrical equipment because of their high electrical resistance.

3. They have a number of advantages over other types of materials.

4. They are an excellent choice for anyone looking for a durable and reliable material that can withstand even the toughest conditions.

5. Whether you need parts for industrial equipment or electrical systems, alumina ceramic is a great option that can deliver the performance and durability you need.

OEM/ODM is acceptable. Your goods will be produced exactly according to your drawings or inquiry

| Item | Test Condition | 95% Al2O3 | 99% Al2O3 | 99.5% Al2O3 | ||

| Physical properties | Density | g/cm3 | >3.6 | 3.89 | 3.96 | |

| Moisture absorption | % | 0 | 0 | 0 | ||

| Mechanical properties | ROHS Hardness | ≥85 | ≥89 | ≥89 | ||

| Flexural strength | psiX103 | 20℃ | 358 | 550 | 550 | |

| Compressive strength | psiX103 | 20℃ | 2068(300) | 2600(377) | 2600(377) | |

| Fracture toughness | Mpa.m3/2 | K(l c) | 4.3 | 5.6 | 6 | |

| Thermal properties | Maximum use temperature | ℃ | 1450 | 1600 | 1650 | |

| Thermal expansion coefficient | 1X10-6/℃ | (25-1000℃) | 7.6 | 7.9 | 8.2 | |

| Thermal shock resistance | ℃ | Tc | 250 | 200 | 200 | |

| Thermal conductivity | w/mok | 20℃ | 16 | 30 | 30.4 | |

| Electrical properties | Volume resistivity | Ohm/cm2 | 100℃ | >1013 | >1014 | >1014 |

| Dielectric breakdown strength | KV/mm | 8.7(220) | 8.7(220) | 8.7(220) | ||

| Dielectric constant | (E) | 1MHz25℃ | 9 | 9.7 | 9.7 | |

| Dielectric constant (100MHz) | (E) | 9.5 | ||||

1. Electronic components: Alumina ceramic parts are used as substrates, insulators, and heat sinks for electronic components such as microchips, circuit boards, and power modules. These components require high thermal conductivity and excellent insulation properties to ensure efficient operation and to prevent damage due to heat buildup.

2. Medical implants and prosthetics: Used for the production of medical implants and prostheses.

3. Chemical processing: AUsed in chemical processing applications due to their resistance to corrosion, high temperatures, and abrasion. These parts can be used in valves, pumps, and pipes, among others, where the harsh chemical environment can cause damage to steel and other materials.

4. Aerospace and defense: These parts can be used in components such as radar systems, missile nose cones, and aircraft engine components.

5. Automotive components: Used in the production of automotive components, particularly in diesel engines due to their thermal shock resistance and improved fuel efficiency. These parts can be used in components such as diesel engine glow plugs, turbocharger bearings, and exhaust gas sensors.

6. Machinery components: Used in the production of machinery components, particularly those that require high strength and wear resistance. These parts can be used in components such as pump seals, bearings, and cutting tools.

7. Thermal spray coatings: Alumina ceramic parts can also be used as thermal spray coatings to provide increased wear resistance and thermal insulation. These coatings are commonly used in components such as turbine blades, aerospace applications, and automotive engine components.

Q1. What information should we supply to get a quote?

Please offer the specification of alumina ceramic crucible, such as shape, dimension, quantity, application etc.

Q2. What applications are alumina ceramic parts suitable for?

Alumina ceramic parts are suitable for a wide range of applications, including medical implants, electronic components, automotive parts, cutting tools, and wear-resistant parts for machinery.

Q3. What sizes and shapes are available for alumina ceramic parts?

Alumina ceramic parts are available in a wide range of sizes and shapes, including rods, tubes, plates, discs, and custom shapes.

Q4. How long do alumina ceramic parts last?

Alumina ceramic parts have a long service life and can last for decades when used in the right applications. Their wear resistance and hardness make them ideal for applications where components are exposed to high levels of stress and wear.

Q5. Are alumina ceramic parts recyclable?

Alumina ceramic parts are not currently recyclable due to their high melting point and resistance to chemical corrosion. However, efforts are being made to develop new methods for recycling these parts in the future.

1. Wear caring gloves and refuge glasses.

2. Use a soft cloth to remove any dust and dirt from the part.

3. Fill the part with warm up water and a mild detergent.

4. Scrub up the part with a soft brush to remove whatever residue.

5. Wash the part with clean water and allow it to dry out completely earlier use.

1. Visual inspection of the part for any signs of damage or irregularities.

2. Measurement of the length, width, and thickness of the part to check for accuracy.

3. Checking for any leaks or pinhole defects in the part.

4. Verification of the material and chemical composition of the part.

1. We supply personalized and customized services to contact your personal needs.

2. We are experienced professionals with a good record of success.

3. We provide superior client service and promptly respond to all inquiries.

4. We provide militant prices and strive to ensure that your funds receive the best value.

5. We use the latest technologies and tools to ensure that your project is completed to the highest standards.

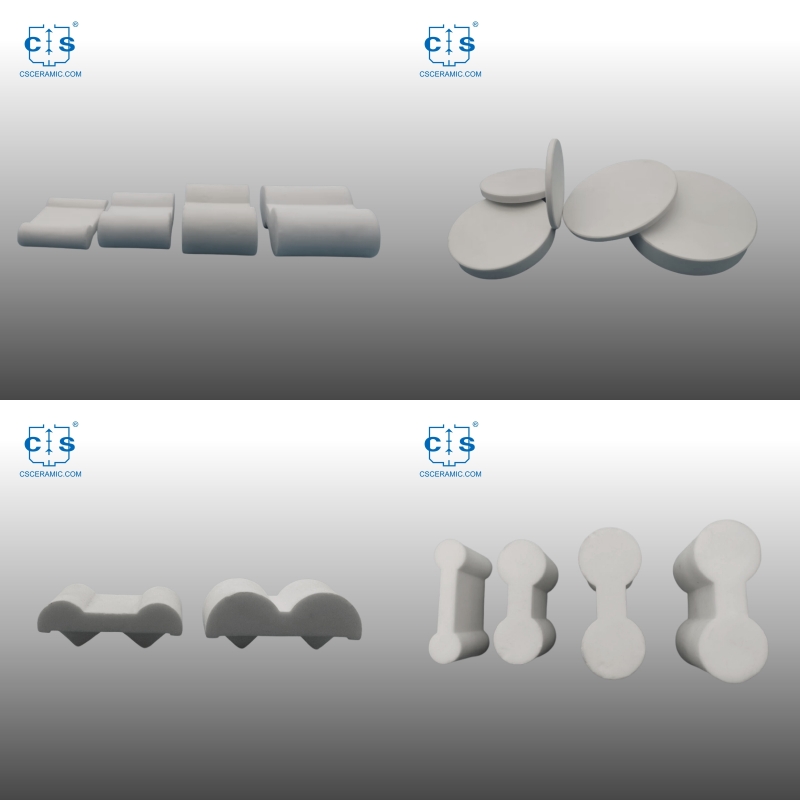

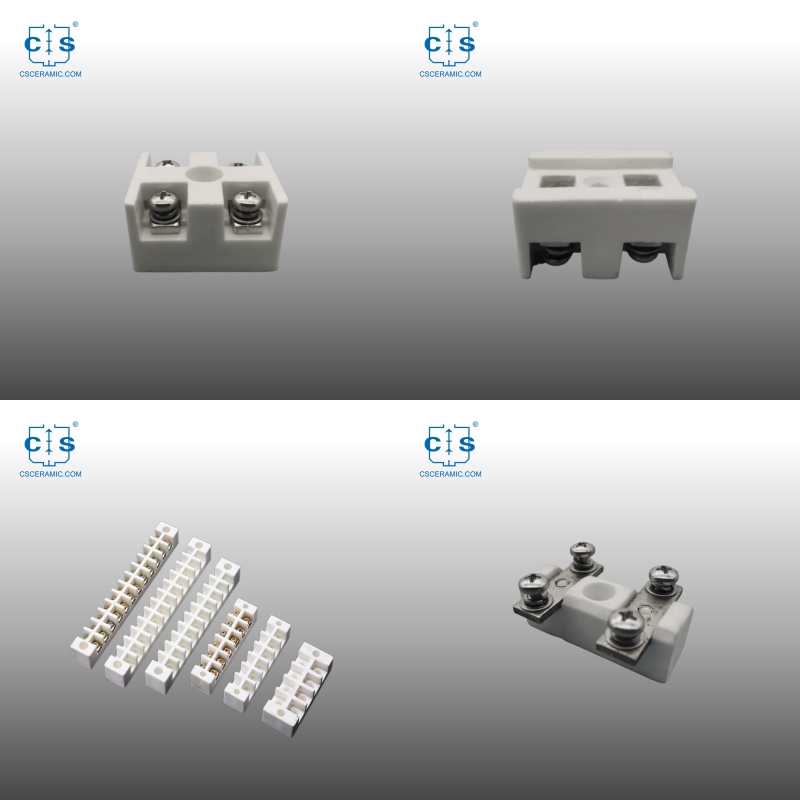

High Mechanical Strength Alumina Steatite Ceramic Parts

High Mechanical Strength Alumina Steatite Ceramic Parts

Alumina steatite ceramic parts are an ideal choice for components that require minimal maintenance and have a long life,they have excellent electrical insulation and thermal shock resistance.Available in various sizes.

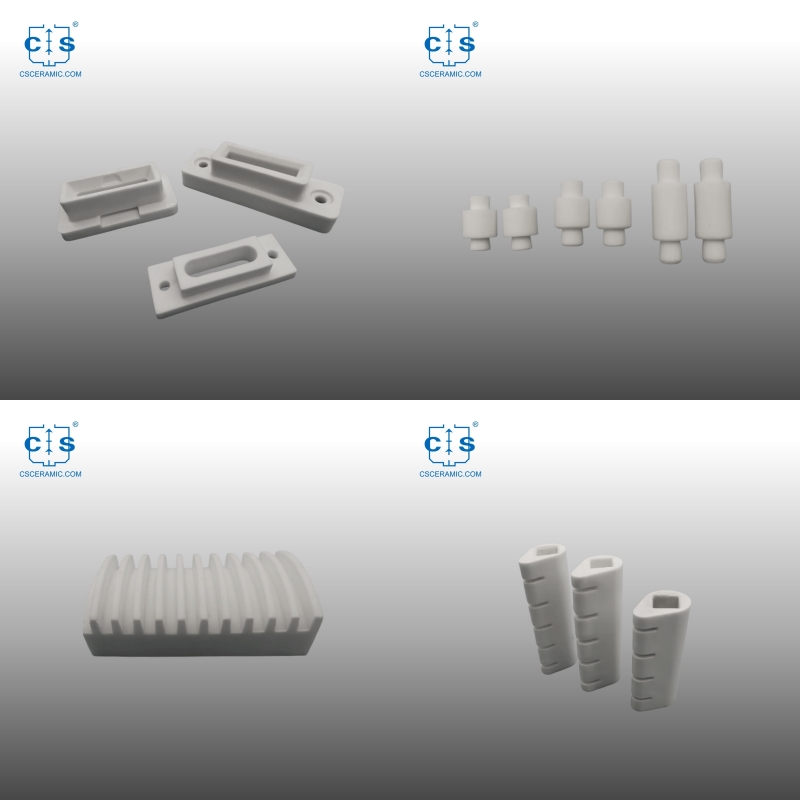

Alumina Ceramic Thermocouple Insulator Tubes

Alumina Ceramic Thermocouple Insulator Tubes

Alumina ceramic thermocouple insulated tubes provide excellent insulation performance and durable durability, used to isolate thermocouples from high temperatures and corrosive environments.Available in various sizes.

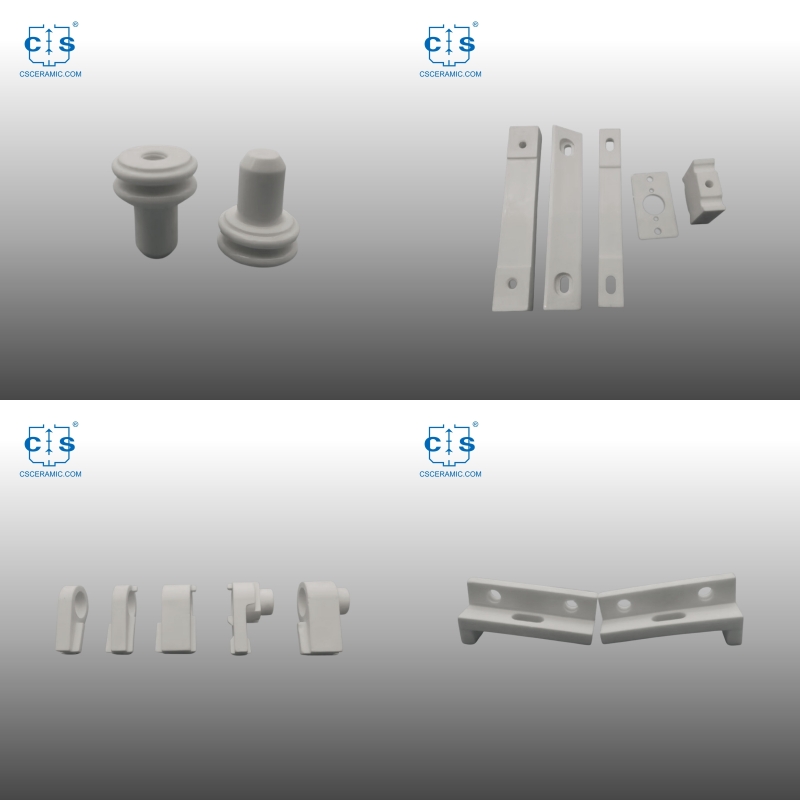

Alumina Ceramic Laser Reflector

Alumina Ceramic Laser Reflector

CS CERAMIC is committed to delivering high-quality alumina ceramic laser reflector tailored to your exact specifications.

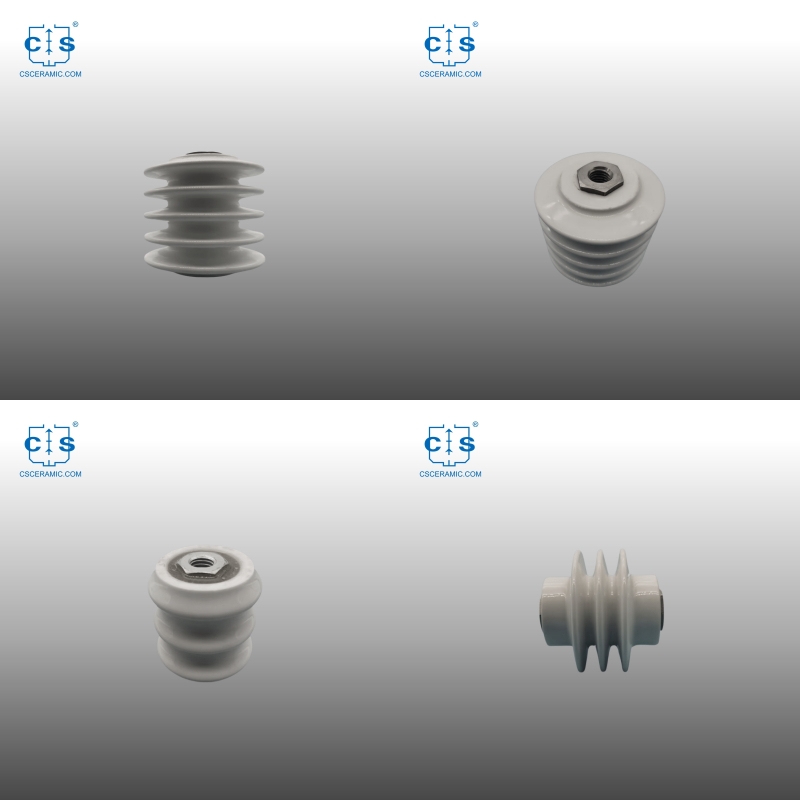

Alumina Bushing Ceramic Insulator

Alumina Bushing Ceramic Insulator

Alumina Bushing Ceramic Insulator for cable terminations. Multiple fluted and capped bushings, re-entrant bushings, tubular bushings, barrel and cylindrical bushings, etc. can be customized.

Alumina Ceramic Ball Bearing Ceramic Bushings

Alumina Ceramic Ball Bearing Ceramic Bushings

Alumina ceramic ball bearing is a type of bearing that uses ceramic balls in order to reduce friction and improve bearing performance.These bushings are designed to reduce maintenance costs and extend the life of equipment.

Industrial Alumina Ceramic Piston Parts

Industrial Alumina Ceramic Piston Parts

Alumina ceramic piston adopts the ultra-hard wear resistance of modern engineering ceramic materials, can be assembled by ceramic metallization bonding,welding and socket technology.Available in various sizes.

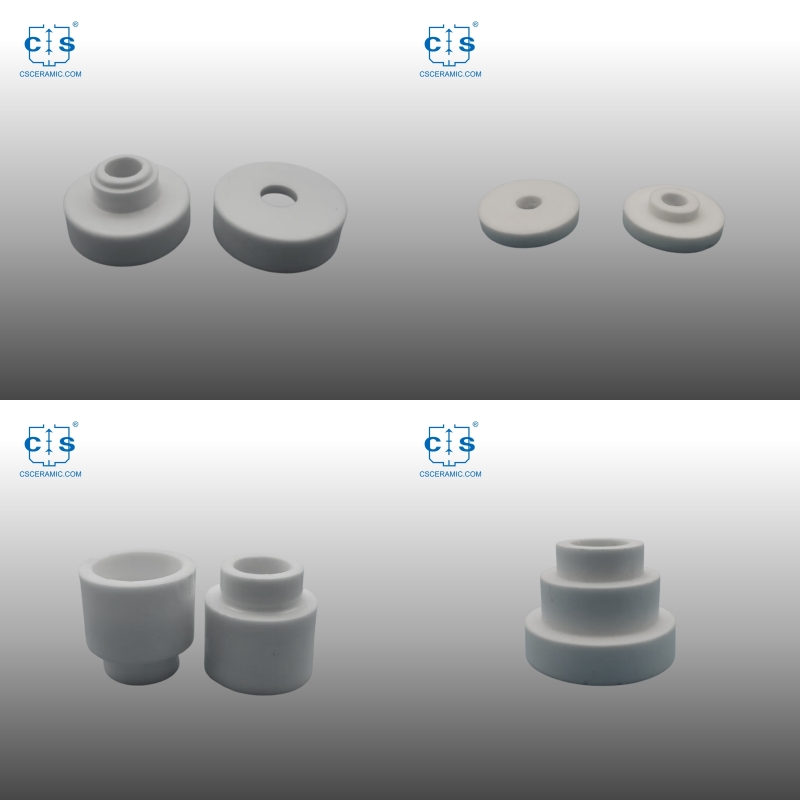

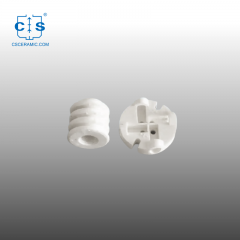

High Alumina Ceramic Washer Ceramic Seal

High Alumina Ceramic Washer Ceramic Seal

Alumina ceramic washer ceramic seal is used as seals for a variety of applications.These rings are designed to provide a tight,reliable seal that won't leak or break down over time.Available in various sizes.

95% to 99% Alumina Ceramic Washer Ceramic Seal Ring

95% to 99% Alumina Ceramic Washer Ceramic Seal Ring

Alumina washer ceramic seal ring is used as seals for a variety of applications. These rings are designed to provide a tight, reliable seal that won't leak or break down over time.All sizes can be customized.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522