Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

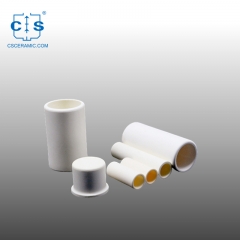

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

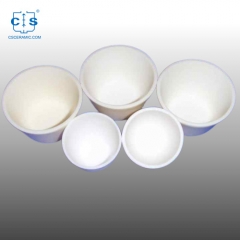

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

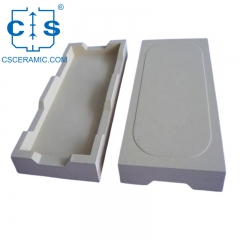

Read MoreZrO2 crucible's extreme heat resistance and excellent thermal shock resistance make it ideal for performing high-temperature processes such as melting and annealing metals, as well as for storing, mixing, and heating hazardous materials.

item no. :

CS-YHG-F001Color :

WhitePort :

Any ports of Chinalead date :

1-7 daysMaterial : Zirconia

Purity : 95%

Shape : Square

1. High Temperature Resistance (up to 2200°C ~ 2400°C)

2. High density (up to 6.0g/cm3)

3. Low thermal conductivity

4. Chemical inertness

5. Resistance to molten metals

6. Lonic electrical conduction

7. Wear resistance

8. High fracture toughness

9. High hardness

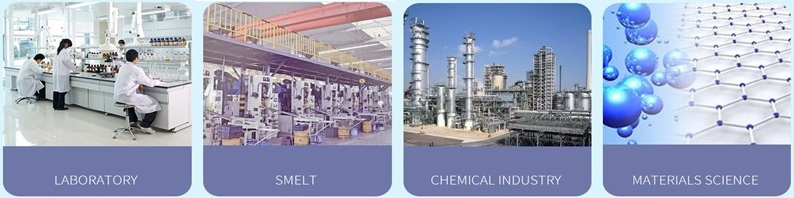

(1) Chemical/metallurgic processes;

(2) Laboratory thermal analysis;

(3) nuclear industries.

Crucible Size Chart

Item

Length /mm

Width /mm

Height /mm

Thickness /mm

Purity

CS-YHG-F001

50

50

15

3

95%

CS-YHG-F002

60

30

20

3

95%

CS-YHG-F003

64

53

17

3

92%

CS-YHG-F004

66

55

16.8

3

92%

CS-YHG-F005

70

45

20

3

95%

CS-YHG-F006

70

70

20

3.5

95%

CS-YHG-F007

75

50

20

3

95%

CS-YHG-F008

98

39

29

3.5

92%

CS-YHG-F009

100

49

16

4

92%

CS-YHG-F010

100

40

20

3

95%

CS-YHG-F011

100

35

10

3.5

95%

CS-YHG-F012

110

110

18

4

95%

CS-YHG-F013

120

22

16

4

92%

CS-YHG-F014

135

135

20

5

95%

CS-YHG-F015

160

80

14

5

92%

CS-YHG-F016

164

164

25

5

95%

CS-YHG-F017

84

84

23

4

95%

CS-YHG-F018

67

67

48

4

95%

CS-YHG-F019

88

62

27

4

95%

P.S. Customized manufacturing is also provided.

Please tell us about product’s parameters such as outer diameter, inner diameter, wall thickness, height, purity, shape, etc. when a customization is needed.

(1) Constitution of ZrO2 crucible

|

Component |

Percentage |

|

Fe2O3 |

<=0.5 |

|

SiO2 |

<=0.5 |

|

ZrO2 |

>=92 |

|

porosity |

<=0.5 |

(2) Maximum size tolerance allowed for ZrO2 crucible (SB17-88)

|

model size |

unit |

limit |

diameter |

height |

deformation |

|

50 |

mm |

<= |

±1 |

±2 |

2% |

|

50~100 |

mm |

<= |

±1.5 |

±2.5 |

3% |

|

100 |

mm |

<= |

±1.5 |

±2.5 |

3.5% |

Zirconia Crucible test standard

1. visible Test: The crucible should be visually inspected for signs of cracks, chips, or other signs of damage.

2. angle Test: The crucible should be weighed to insure that it meets the stated weight requirements.

3. thermic Shock Test: The crucible should be subjected to thermic shock testing to ensure that it can withstand fulminant changes in temperature without cracking or deforming.

4. energy Expansion Test: The crucible should be heated to a temperature above the thaw direct of the material and then cooled to control that it can withstand thermal stresses.

5. Impact Test: The crucible should be dropped from a predetermined tallness to verify that it can resist physical science impacts.

6. Corrosion underground Test: The crucible should be exposed to different undefined agents to insure that it is resistant to corrosion.

7. flex Test: The crucible should be bent to control that it is strong enough to withstand physics forces.

Carefully packed by wooden boxes with padded foams.

Zirconia Ceramic crucible OEM requests

1.We can customize the crucibles based on the customer's specifications, such as size, shape, type, etc.

2.Additionally, we can provide custom branding on the crucibles, as well as color customization.

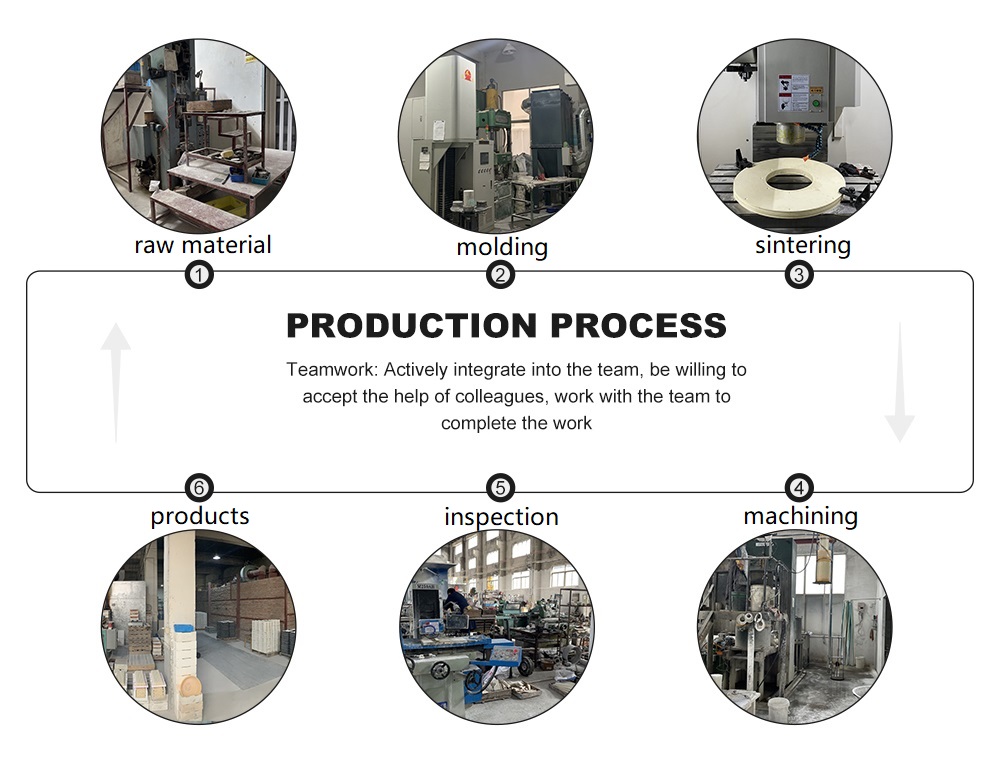

As a professional industrial ceramic supplier, we have a series of advantages that guarantee our market share in the international trade market.

1.Reliable quality control, complete specifications, support customization of non-standard products

2.Professional and committed service team

3.Multiple protection of packaging, secure and reliable

4.Highly efficient delivery channel, safe and rest-assured

FAQ

1.Q1: What is a zirconia smelting crucible?

A: A zirconia smelting crucible is a special type of crucible used for smelting and melting metals and alloys. It is made from a special type of zirconia ceramic, which is highly resistant to corrosion, heat, and other harsh conditions. This makes it ideal for melting down metals and alloys for casting and other manufacturing processes.

2.Q:What's the delivery time?

A: 1-7 working days for standard products 20-30 days for customized products.

3. Q:What is the maximum temperature that a zirconia ceramic crucible can withstand?

A:The maximum temperature that a zirconia ceramic crucible can withstand is around 2,200°C (4,000°F).

4. Q:Are there any safety precautions that need to be taken when using a zirconia ceramic crucible?

A:Yes, it is important to wear protective gear when using a zirconia ceramic crucible.

Related Products

Cylinder Zirconia ceramic refractory crucibles Zirconia Sintering Dental Saggar with Lid

Cylinder Zirconia ceramic refractory crucibles

Cylinder Zirconia ceramic refractory crucibles

Zirconia crucibles with a purity of 99%, a density of 5.5~6.0g/cm3 and a maximum working temperature of 2200°C are mainly used in the melting of precious metals.

Round Zirconia Sintering Dental Saggar with Lid

Round Zirconia Sintering Dental Saggar with Lid

Zirconia sagger is a type of sintering tray widely used in muffle furnaces, tube furnaces, and tunnel furnaces.

High-Temp Zirconia Ceramic Tray Acid Alkali Resistant Crucible

High-Temp Zirconia Ceramic Tray Acid Alkali Resistant Crucible

High-Efficiency Zirconia Ceramic Tray, designed with a dish-like shape featuring a large base and low height, available in both circular and square configurations to suit your needs. These trays are renowned for their exceptional high-temperature resistance, acid-alkali corrosion resistance, and superior strength, making them ideal for use in high-1

Arc-shaped Zirconia Metal Melting Crucible

Arc-shaped Zirconia Metal Melting Crucible

Zirconia crucibles are specifically designed for melting superalloys and precious metals.Crucibles made of zirconia can provide cleaner melts when heated up to max. temperatures of 2200°C.

Diameter 130mm Porcelain Desiccator Plate with Small Holes

Diameter 130mm Porcelain Desiccator Plate with Small Holes

1.Diameter of Porcelain Desiccator Plate 130mm 2.Center hole diameter 33mm. Large hole diameter 30mm 3.Small hole diameter 27mm

Standard sample carrier /Sample sensor DSC-TG thermocouple Type P(PtRh)For Netzsch TG 209 F1 Libra TGA 209

Standard sample carrier /Sample sensor DSC-TG thermocouple Type P(PtRh)For Netzsch TG 209 F1 Libra TGA 209

Sample Carrier Type P Temperature Sensor For Netzsch TG 209 F1 Libra

Standard Aluminum Sample Pans 900786.901 for TA Instruments ( Sample Cups)

Standard Aluminum Sample Pans 900786.901 for TA Instruments ( Sample Cups)

TA Solid sample test Aluminum Sample Pans for TA Instruments Q100/Q10. Manufacturer for TA crucibles and DSC sample pans. TA Instruments good alternative sample cups. TA 900786.901.

Zirconia Ceramic Ball Bearings

Zirconia Ceramic Ball Bearings

We offer 600+ kinds of zirconia zro2 ceramic bearings, including deep groove ball bearing, inserting bearing,self-aligning ball bearing, thrust ball bearings, angular contact bearing, etc.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522