Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read Moreitem no. :

CS-BB-01Color :

WhitePort :

Any ports of Chinalead date :

1-7 daysMaterial : Zirconia ceramic

Shape : Round

1.Zirconia all-ceramic bearings have features of magnetoelectric insulation resistance, wear resistance and corrosion resistance, oil-free self-lubrication,

high temperature resistance and high cold resistance,

2.It can be used in harsh environments and special working conditions.

3.Rings and rolling elements are made of Zirconia (ZrO2) ceramic materials,

4.For material of retainer, polytetrafluoroethylene (PTFE) is standard configuration, generally glass fiber reinforced nylon dragon 66(GRPA66-25), special engineering plastics (PEEK, PI), stainless steel (AISI SUS316, SUS304), brass (Cu), etc. can be also used.

1. Corrosion resistance: The material itself has corrosion resistance, and can be applied to strong acid other than hydrofluoric acid, strong alkali, inorganic and organic salt, seawater and other fields. It is suitable for working under harsh conditions where is full of corrosive media, such as plating equipment, electronic equipment, chemical machinery, ship manufacturing, medical apparatus and instruments, etc.

2. High temperature resistance: between 180℃ and 260℃, ceramic bearings with retainers will not have expansion due to temperature difference. Working temperature of zirconia ceramic bearing filled with balls is between 300℃ and 800℃, and can be applied to high temperature equipment like furnace kilns, plastic and steel manufacturing devices.

3. Self-lubrication: Ceramic bearings have good self-lubricating property for their small friction coefficient and good surface smoothness, especially silicon nitride material, whose self-lubricating performance is excellent. Therefore, ceramic bearing do not need any grease. Under vacuum environment, problem of lubrication for ordinary bearings can be overcome with application of ceramic bearing.

4. Anti-magnetism: Because there is no magnetism and without dust absorption, so problem of early peeling off and loud noise can be reduced, for which it can be used in fields of demagnetization equipment and instruments.

5. Electrical insulation: due to its high resistance, arc damage to bearings can be avoided, so it can be used for power equipment with insulation requirement.

6. Density of ceramic rolling balls is lower than that of steel and their weight is much lighter, therefore, the centrifugal effect on the outer ring during rotation can be reduced by 40%, thus greatly prolonging the service life.

7. Ceramic is less affected by heat expansion and cold contraction than steel, so with constant clearance, bearing can be allowed to work in environment with severe temperature difference.

8. The elastic modulus of ceramics is higher than that of steel, and it is not easy to deform under stress. Therefore, it is conducive to improving the working speed and achieving higher precision.

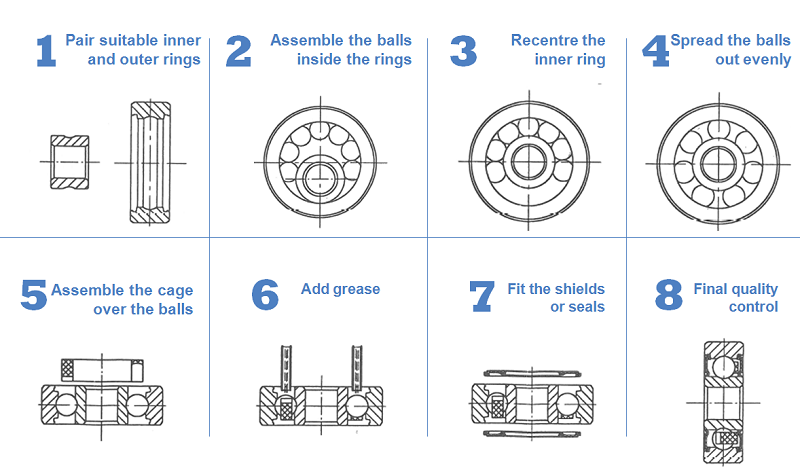

Instructions for installation and use of ceramic bearings.

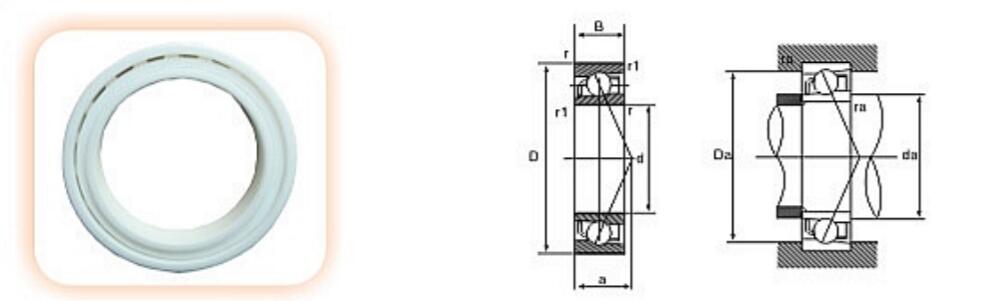

Angular contact ball bearings--Size details (Click this button)

Double row angular contact ball bearings--Size details (Click this button)

Self-aligning ball bearings--Size details (Click this button)

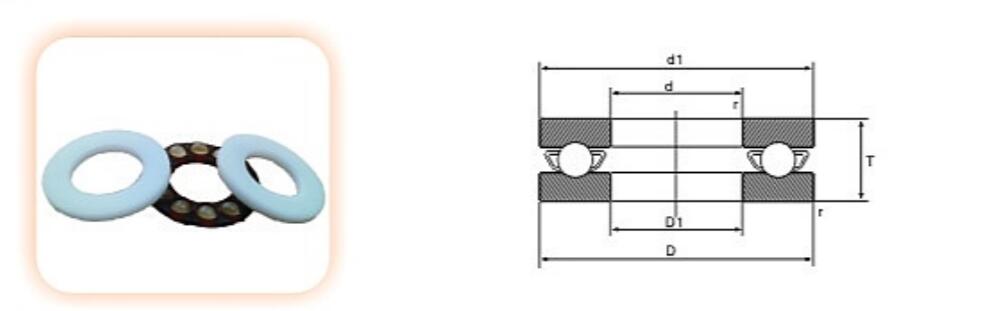

Single direction ball bearings--Size details (Click this button)

Insert bearing--Size details (Click this button)

| Performance parameters of bearing ceramic materials: | ||||||

| Item | Unit | Silicon nitride Si3N4 | Zirconia ZrO2 | Alumina 99.5% A12O3 | Silicon carbide | Bearing steel |

| Density | g/cm³ | 3.23 | 6.05 | 3.92 | 3.12 | 7.85 |

| water absorption | % | 0 | 0 | 0 | 0 | 0 |

| Thermal expansion coefficient | 10-6/K | 3.2 | 10.5 | 8.5 | 3 | 12.5 |

| Young's modulus of elasticity | Gpa | 300 | 210 | 340 | 440 | 208 |

| Poisson's ratio | ∕ | 0.26 | 0.3 | 0.22 | 0.17 | 0.3 |

| Hardness (Hv) | Mpa | 1500 | 1200 | 1650 | 2800 | 700 |

| Bending strength (room temperature) | Mpa | 720 | 950 | 310 | 390 | 520 (tensile strength) |

| Bending strength (700℃) | Mpa | 450 | 210 | 230 | 380 | ∕ |

| Compressive strength (room temperature) | Mpa | 2300 | 2000 | 2200 | 1800 | ∕ |

| Fracture toughness | Mpa*m | 6.2 | 10 | 4.2 | 3.9 | 25 |

| Thermal conductivity (room temperature) | W/m*k | 25 | 2 | 26 | 120 | 40 |

| Specific resistivity (room temperature) | Ω*mm2/m | >1013 | >1015 | >1016 | >103 | 0.1-1 |

| Maximum working temperature (without load) | ℃ | 1050 | 750 | 1750 | 1550 | 300 |

| Acid and alkali corrosion resistance | ∕ | Strong | Strong | Strong | Strong | Weak |

| Inner and outer rings/Ball/cage | Load capacity | Limiting speed | Anti-corrosion | Long-time working temp | Used costs |

| ZrO2/ZrO2/PA | ★★★★★ | ★★★★★ | ★★ | 90℃ | ★★★★★★ |

| ZrO2/ZrO2/PTFE | ★★★★★ | ★★★★★ | ★★★★★★★ | 180℃ | ★★★★★★ |

| ZrO2/ZrO2/PEEK | ★★★★★ | ★★★★★ | ★★★★★ | 260℃ | ★★★★★★ |

| ZrO2/ZrO2/PI | ★★★★★ | ★★★★★ | ★★★★★ | 300℃ | ★★★★★★ |

| ZrO2/ZrO2/(no cage) | ★★★★★★ | ★★★★★★ | ★★★★★★★ | 400℃ | ★★★★★★ |

| Si3N4/Si3N4/PTFE | ★★★★★★ | ★★★★★★ | ★★★★★★★ | 180℃ | ★★★★★★★ |

| Si3N4/Si3N4/PEEK | ★★★★★★ | ★★★★★★ | ★★★★★ | 260℃ | ★★★★★★★ |

| Si3N4/Si3N4/PA | ★★★★★★ | ★★★★★★ | ★★ | 90℃ | ★★★★★★★ |

| Si3N4/Si3N4/(no cage) | ★★★★★★ | ★★★★★ | ★★★★★★★ | 1100℃ | ★★★★★★★ |

| Si3N4/Si3N4/PI | ★★★★★★ | ★★★★★★ | ★★★★★ | 300℃ | ★★★★★★★ |

| POM/PA/(glass) | ★★★ | ★★★ | ★★ | 90℃ | ★ |

| POM/PA/316 | ★★★ | ★★★ | ★★ | 90℃ | ★ |

| HDPE/HDPE/(glass) | ★★ | ★★ | ★★★★ | 80℃ | ★ |

| HDPE/HDPE/316 | ★★ | ★★ | ★★★ | 80℃ | ★ |

| PP/(glass)/PP | ★★ | ★★ | ★★★★ | 85℃ | ★ |

| PEEK/ZrO2/PEEK | ★★★ | ★★★★★ | ★★★★★ | 260℃ | ★★★★★ |

| PEEK/ZrO2/PTFE | ★★★ | ★★★★★ | ★★★★★ | 180℃ | ★★★★★ |

| UPE/ZrO2/UPE | ★★ | ★★ | ★★★★ | 80℃ | ★★★★ |

| PTFE/ZrO2/PTFE | ★ | ★ | ★★★★★★★ | 180℃ | ★★★★ |

| PVDF/ZrO2/PVDF | ★★★ | ★★★ | ★★★★★★ | 150℃ | ★★★★ |

| 440C/440C/304 | ★★★★★★★ | ★★★★★★★ | ★ | 180℃ | ★ |

| 316/316/316 | ★★★★ | ★★★★ | ★★★ | 180℃ | ★★ |

| 304/304/304 | ★★★★ | ★★★★ | ★★ | 180℃ | ★★ |

| 316L/316L/316L | ★★★★ | ★★★★ | ★★★ | 180℃ | ★★ |

| 440C/ZrO2/304 | ★★★★★★ | ★★★★★★ | ★ | 180℃ | ★★★ |

| 440C/Si3N4/304 | ★★★★★★★ | ★★★★★★★ | ★ | 180℃ | ★★★ |

| 316/ZrO2/PTFE | ★★★★ | ★★★★ | ★★★ | 180℃ | ★★★★ |

| 316/Si3N4/316 | ★★★★ | ★★★★ | ★★★ | 180℃ | ★★★★★ |

| GCr15/GCr15/08F | ★★★★★★★ | ★★★★★★★ | ★ | 120℃ | ★ |

| GCr15/ZrO2/08F | ★★★★★★ | ★★★★★★ | ★ | 120℃ | ★ |

| GCr15/Si3N4/08F | ★★★★★★★ | ★★★★★★★ | ★ | 120℃ | ★★ |

When install bearings, equal pressure must be exerted on the circumference of the ferrule end face.

Carefully packed by wooden boxes with padded foams.

1.Density: The density of zirconium oxide ceramic bearings should be between 5.9 and 6.1 g/cm3.

2. Hardness: The Vickers hardness of zirconia ceramic bearings should be greater than 11.0 GPa.

3. Strength: The flexural strength of zirconia ceramic bearings should be greater than 1000MPa.

4. Wear resistance: The wear thin value of zirconium oxide ceramic bearings should be to a lesser extent than 0.01mm3/Nm.

5. Thermal shock resistance: The thermal shock underground of zirconium dioxide ceramic bearings should be greater than 200°C.

6. Corrosion resistance: The corrosion resistance of zirconia undefined bearings should be greater than 4.0 on a Mohs scale.

7. Electrical insulation: The electrical insulation of zirconia undefined bearings should be greater than 20MΩ/cm.

1.Our companies offer OEM services for zirconia bearings.

2..We will produce the bearings according to your specifications and provide them to you in bulk for your own use.

3.The bearings can also be customized with different coatings or lubricants to improve performance and extend the service life of the bearing.

4.In addition, Our service offer a variety of accessories to accompany the bearing, such as seals, shields, and bushings.

As a professional industrial ceramic supplier, we have a series of advantages that guarantee our market share in the international trade market.

1.Reliable quality control, complete specifications, support customization of non-standard products;

2.Professional and committed service team;

3.Multiple protection of packaging, secure and reliable;

4.Highly efficient delivery channel, safe and rest-assured.

1. Q: What are Zirconia Ceramic Ball Bearings?

A: Zirconia Ceramic Ball Bearings are a type of bearing which uses ceramic balls instead of traditional steel or other metal balls. They provide superior performance and are often used in applications where high temperatures, corrosive environments, extreme speeds, and low noise levels are desired. The ceramic material used allows for much higher heat tolerances and resistances to abrasion than traditional bearing materials.

2.Q: What are the advantages of using zirconia ceramic ball bearings?

A: Zirconia ceramic ball bearings offer many advantages including higher load capacity, higher speed, greater wear resistance, lower friction, and higher temperature stability. They are also lighter, more durable, and more resistant to corrosion than their steel and stainless steel counterparts. Additionally, they can be used in applications where extreme temperatures are present due to their higher temperature limits.

Transparent 99.98% Quartz Glass Tubes with Both Ends Open

Transparent 99.98% Quartz Glass Tubes with Both Ends Open

Quartz glass tubes have thermal and chemical resistance, optical clarity, and mechanical strength. Available in a variety of lengths, diameters, and wall thicknesses to meet different application requirements.

85μl Pt/Platinum sample pan with lid same size as Netzsch GB399205/GB399860

85μl Pt/Platinum sample pan with lid same size as Netzsch GB399205/GB399860

Platinum purity 99.95% Platinum Crucibles for Netzsch TDA DSC and TGA measurements. Manufacturer for Netzsch crucibles and sample cups. Netzsch Instruments good alternative DSC sample pans.

Al2O3 Precision Alumina Ceramic Components/Parts

Al2O3 Precision Alumina Ceramic Components/Parts

Alumina ceramic components parts are a cost-effective material choice. Available in various sizes and shapes. Our industrial ceramic parts include tube, rod, plate, disc, wafer, ring, seal, bearing, valves, pump plunger, beam, roller, shaft, screw, washer, sleeve, hunger, spacer, holder, carrier, insulator, fixture, clamp, chuck, nozzle, guide, fra1

Standard aluminum Hermetic sample lids 900794.901 for TA Instruments Q10/Q100 ,Auto DSC 29X0 Replacement Parts

Standard aluminum Hermetic sample lids 900794.901 for TA Instruments Q10/Q100 ,Auto DSC 29X0 Replacement Parts

TA 900794.901 TA Liquid sample test Aluminum Sample lids for TA Instruments Q100/Q10. Manufacturer for TA crucibles and DSC sample pans. TA Instruments good alternative sample cups.

40μl High pressure capsules, gold plated same size as TA 900814.901 for TA Instruments

40μl High pressure capsules, gold plated same size as TA 900814.901 for TA Instruments

Gold plated High pressure capsules,TA stainless steel thread high-pressure crucible(TA thread high-pressure stainless steel crucible), used along with gold plated gasket. Manufacturer for TA crucibles and DSC sample pans.TA Instruments good alternative sample cups.

OEM 85μl Alumina ceramic crucibles With R arc for Mettler Toledo (Sample pans)

OEM 85μl Alumina ceramic crucibles With R arc for Mettler Toledo (Sample pans)

DSC crucibles, Alumina crucibles sample pans for Mettler DSC and SDTA measurements. Thermal analysis consumables for Manufacturer for dsc polymer Mettler Toledo crucibles and sample pans.

Transparent 99.98% Quartz Glass Beaker

Transparent 99.98% Quartz Glass Beaker

99.98% quartz glass beaker has high economic benefits,and is an essential piece of equipment for any laboratory or research facility requiring precise measurements and accurate results.Available in various sizes.

Advanced Alumina Ceramic Pump/Shaft

Advanced Alumina Ceramic Pump/Shaft

Alumina ceramic shaft has unique design and structure ensure that it can withstand the stress and strain of high-pressure and high-temperature environments, while minimizing the wear of pump components.Available in various sizes and shapes.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522