Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read Moreitem no. :

CS-THG-J20001Color :

BlackPort :

Any ports of Chinalead date :

5-7 daysMaterial : Silicon Carbide

Purity : 98.5%

Shape : Tube

Original Country : China

1.High-temperature resistance: Silicon carbide is an excellent material for use in high-temperature applications, as it is able to withstand temperatures up to 2200°C.

2.Corrosion resistance: Silicon carbide is highly resistant to corrosion, even in acidic environments.

3. Wear resistance: Silicon carbide is extremely hard and durable, making it an ideal material for sandblasting nozzles.

4.Low thermal expansion: Silicon carbide has a low thermal expansion rate, which is important for applications that involve rapid changes in temperature.

5.High thermal conductivity: Silicon carbide has a high thermal conductivity, which helps to dissipate heat quickly and efficiently.

6. Low density: Silicon carbide has a low density, which helps to reduce the weight of the nozzle.

7. Low cost: Compared to other materials, silicon carbide is relatively inexpensive, making it a cost-effective solution for sandblasting nozzles.

Burner Nozzle Applications

1.Silicon Carbide sandblasting nozzles are ideal for use in a variety of industries including automotive, aerospace, medical, industrial, and many others.

2.They are highly effective at blasting away dirt, rust, and other contaminants from a variety of surfaces including metal, ceramic, and other materials.

3.They can also be used for surface preparation, such as cleaning and smoothing prior to painting or powder coating.

4.Silicon Carbide sandblasting nozzles are also ideal for cleaning and removing rust, paint, and other contaminants from metal and other surfaces.

5.They are also excellent for cleaning and removing metal deposits from surfaces prior to welding or other fabrication processes.

6.Additionally, they can be used for general cleaning, polishing, and smoothing of surfaces.

| Item | Unit | SiC | SSiC |

| Purity | % | ≥90 | ≥98 |

| Density | G/cm3 | 3.05 | 3.1 |

| Shore Hardness | HS | 110-125 | 120-130 |

| Elastic Modulus | MPa | 4.12*105 | 4.10*10s |

| Poisson Ratio | 0.15 | 0.16 | |

| Tensile Strength | MPa | 2.75*102 | 2.8*102 |

| Bending Strength | MPa | 4.41*102 | 4.9*102 |

| Compression Strength | MPa | 2.94*103 | 3.0*102 |

| Thermal Conductivity | W/m.k | 141 | 147 |

| Coefficient of Thermal Expansion | I/℃ | 4.3*10-6 | 4.0*10-6 |

| Heat Resistance | 1600C | 165CTC | |

| Tolerance | Mm | -0.02——+0.02 | -0.02——+0.02 |

| Acid Resistance |

5 times higher than the usual TC |

Resist all chemical media |

| Item | Bottom Length along with edge(mm) |

Bottom OD

(mm)

|

Bottom ID

(mm)

|

Top OD (mm) |

Top ID

(mm)

|

Tupe Height

(mm)

|

Ttl Height (mm) | Purity |

| CS-THG-J20001 | 30 | 18 | 12 | 24 | 18 | 75 | 100 | 98.5% |

| CS-THG-J20002 | 65 | 54 | 44 | 60 | 50 | 230 | 260 | 98.5% |

| CS-THG-J20003 | 90 | 74 | 66 | 80 | 72 | 250 | 280 | 98.5% |

| CS-THG-J20004 | 140 | 126 | 114 | 132 | 120 | 360 | 300 | 98.5% |

| CS-THG-J20005 | 157 | 140 | 124 | 147 | 131 | 280 | 310 | 98.5% |

| CS-THG-J20006 | 178 | 150 | 136 | 160 | 146 | 370 | 390 | 98.5% |

| CS-THG-J20007 | 204 | 175 | 159 | 184 | 168 | 410 | 460 | 98.5% |

| CS-THG-J20008 | 283 | 250 | 230 | 263 | 243 | 480 | 510 | 98.5% |

| CS-THG-J20009 | 350 | 308 | 288 | 320 | 300 | 510 | 550 | 98.5% |

| CS-THG-J20010 | 410 | 362 | 342 | 370 | 350 | 540 | 590 | 98.5% |

| CS-THG-J20011 | 500 | 450 | 430 | 460 | 440 | 530 | 600 | 98.5% |

The performance testing of a silicon carbide sandblasting burner nozzle should include the following:

1. Pressure drop: This test measures the pressure drop across the nozzle as air is forced through it. This is important to ensure the nozzle is able to deliver the desired air pressure and flow rate.

2. Flow rate: This test measures the rate at which air is forced through the nozzle. This is important to ensure the nozzle is able to deliver the desired air pressure and flow rate.

3. Temperature: This test measures the temperature of the air coming out of the nozzle. This is important to ensure the nozzle is able to deliver the correct temperature for the sandblasting application.

4. Particle size: This test measures the size of the particles coming out of the nozzle. This is important to ensure the nozzle is able to deliver the correct particle size for the sandblasting application.

5. Durability: This test measures the durability of the nozzle. This is important to ensure the nozzle is able to withstand the wear and tear associated with sandblasting applications.

SiC Nozzle's Use/Maintenance Methods

1. The amount of oil injection depends on the length of the injection time.According to the different control methods of the electromagnetic coil, the injector can be divided into voltage drive and current drive.The voltage pattern can also be divided into low resistance and high resistance.High resistors can be connected to 12V of electricity, while low resistors can only be connected to low voltages.The coil will burn if it is incorrectly connected to 12V for a long time.When the fuel is injected, the voltage provided by the computer is constant, such as 12V, and will immediately change to 0V when the oil is off.The change is instantaneous, like the concepts of 0 and 1 in computer language, without saying 0.5 in between;

2. In the same type of EFI vehicle, the pressure of the gasoline pump is constant.Regardless of the throttle opening, the pressure of the silicon carbide nozzle is always constant as long as it is regulated by the fuel pressure regulator.The silicon carbide nozzle is strictly matched to the fuel pump and fuel pressure regulator and has only the designed pressure.Can achieve the atomization effect of silicon carbide nozzle, the pressure is lower than the design pressure, the oil is not mist but column, not suitable for mixing with air;If the pressure is too high, the oil emitted is conical and difficult to mix, and the injection force is too large, a large amount of fuel is directly injected on the pipe wall, which directly affects the mixing ratio parameters.The pressure should be constant whether accelerating or idling, and different models have different pressures.3: When cleaning the silicon carbide nozzle, you can not damage the silicon carbide nozzle. For example, it is suggested that you can use a soft brush to clean the silicon carbide nozzle.

As a professional industrial ceramic supplier, we have a series of advantages that guarantee our market share in the international trade market .

1. Sufficient inventory (delivery within 1-3 days);

2, complete size (caliber 30-500mm height 100-600mm);

4. Long service life;

5, quality assurance (each nozzle nozzle has passed 100% strict inspection before leaving the factory);

6, quality commitment (quality problems we bear back and forth freight package return package);

7, preferential prices (production direct sales manufacturers, production enterprises, global direct sales);

8. Excellent service (customized according to customer's requirements);

9. Sincere attitude (professional and technical personnel analyze and solve various desulfurization and dust removal problems for customers).

FAQ

1.Q: What are the benefits of using a silicon carbide sandblasting burner nozzle?

A: Silicon carbide sandblasting burner nozzles offer many benefits, including improved surface finish, higher pressure, and better coverage. They are also more efficient than other types of nozzles, as they require less air to power and use less abrasive material. Additionally, they produce less dust and debris, which makes them safer to use.

2.Q: How do I properly maintain a silicon carbide sandblasting burner nozzle?

A: To ensure that your silicon carbide sandblasting burner nozzle continues to function properly, it is important to regularly inspect and clean it. This includes regularly inspecting the nozzle for wear and tear, and replacing any worn parts. Additionally, it is important to ensure that the nozzle is regularly cleaned to remove any built-up debris and to prevent any clogging.

Silicon Carbide Vortex Sandblasting Nozzle

Silicon Carbide Vortex Sandblasting Nozzle

SiC vortex nozzles are used for waste gas washing, desulphurization and denitrification, flue gas dust removal, fire prevention and fire extinguishing.

Full Cone Silicon Carbide Spray Nozzle

Full Cone Silicon Carbide Spray Nozzle

SiC spray nozzle full cone is a nice choice as a key component for desulfurization and dust removal in thermal power plants, due to its high hardness, erosion resistance, corrosion resistance, and oxidation resistance.

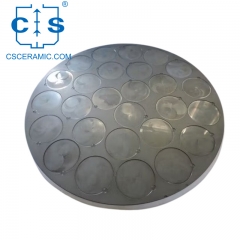

OEM Thermal analysis sample tray /Alumina dsc sample pan

OEM Thermal analysis sample tray /Alumina dsc sample pan

OEM Thermal Analysis sample pan Alumina crucibles sample pans for STDA DSC and TGA measurements.

High-Purity Quartz Blowtorch for Welding Fused Silica Torch

High-Purity Quartz Blowtorch for Welding Fused Silica Torch

High-purity quartz torch, resistant to high temp, thermal shock, & corrosion, is ideal for quartz product processing: welding, polishing, & more.

Magnesia Ceramic Foam Filter Enhances Casting Quality

Magnesia Ceramic Foam Filter Enhances Casting Quality

MgO foam filters feature high porosity, low flow resistance, and effective filtration, enhancing magnesium alloy casting quality by reducing defects.

High-Temp Aluminum Nitride Heating Plate for Production, Analysis, Research

High-Temp Aluminum Nitride Heating Plate for Production, Analysis, Research

The aluminum nitride heating plate boasts high temp & corrosion resistance, high thermal conductivity, widely used in production, analysis, & research.

25μl Fused silica crucible equivilent to Netzsch J5900881 for STA 2500 Regulus

25μl Fused silica crucible equivilent to Netzsch J5900881 for STA 2500 Regulus

J5900881 Netzsch Fused silica crucible for TSTA 2500 Regulus

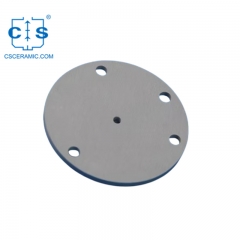

High-Purity SiC Tray for Semiconductor RTA PVD ICP CMP Processes

High-Purity SiC Tray for Semiconductor RTA PVD ICP CMP Processes

The high-purity silicon carbide tray, formed through sintering, serves as a durable carrying device in semiconductor manufacturing processes like RTA, PVD, ICP, and CMP.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522