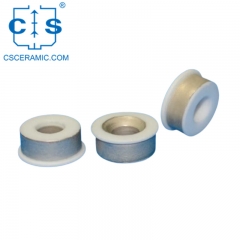

Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read MoreBalls are made of ceramic SiC with high hardness, self-lubricating properties, low thermal expansion coefficient and extreme corrosion resistance.

item no. :

CS-THG-Q10001Color :

BlackPort :

Any ports of Chinalead date :

1-7 daysMaterial : Silicon carbide

Purity : 95%~99%

Shape : Round

Original Country : China

1. Provide excellent wear and corrosion resistance due to their extreme hardness and low friction.

2. Can operate at higher temperatures than steel balls, and they can be used in a variety of extreme environments.

3. Lighter than steel balls, providing better dynamic balance and less vibration.

4. Suitable for applications requiring high load capacity, surface finish, and dimensional accuracy.

5. Cost-effective compared to other high-performance materials.

6. Available in a wide range of sizes and shapes, making them suitable for a variety of applications.

Ceramic Balls Accuracy Grade

Grade

Vdws

△Sph

Ra

Vdwl

Gauge space

Gauge value

Subgauge space

Subgauge

3

0.08

0.08

0.01

0.13

0.5

-5....-0.5.0.+0.5...+5

0.1

-0.2-0.1.0,+0.1,+0.2

5

0.13

0.13

0.014

0.25

1

-5....-0.5.0.+0.5...+5

0.2

-0.4,-0.2,0,+0.2,+0.4

10

0.25

0.25

0.02

0.5

1

-9....-1.0.+1...+9

0.2

-0.4.-0.2.0,+0.2.+0.4

16

0.4

0.4

0.025

0.8

2

-10....-2.0+2...+10

0.4

-0.8,-0.4,0,+0.4,+0.8

20

0.5

0.5

0.032

1

2

-10....-2.0+2...+10

0.4

-0.8,-0.4.0,+0.4.+0.8

24

0.6

0.6

0.04

1.2

2

-12....-2.0+2...+12

0.4

28

0.7

0.7

0.05

1.4

2

-12....-2.0+2...+12

0.4

-0.8,-0.4.0.+0.4.+0.8

40

1

1

0.06

2

4

-16....-4.0+4...+16

0.8

-1.6.-0.8,0,+0.8,+1.6

60

1.5

1.5

0.08

3

6

-16....-4.0+4...+16

1.2

-2,-1.2.0.+1.2.+2

100

2.5

2.5

0.1

5

10

-40....-10.0+10...+40

2

-4.-2.0.+2.+4

200

5

5

0.15

10

15

-60....-15.0+15...+60

3

-6,-3,0,+3,+6

Item

Grade

OD(mm)

Purity

Subject

CS-THG-Q10001

G10

1

95%

Polished

CS-THG-Q10002

G10

1.588

95%

Polished

CS-THG-Q10003

G10

2

95%

Polished

CS-THG-Q10004

G10

2.381

95%

Polished

CS-THG-Q10005

G10

3.175

95%

Polished

CS-THG-Q10006

G10

3.939

95%

Polished

CS-THG-Q10007

G10

4.763

95%

Polished

CS-THG-Q10008

G10

5

95%

Polished

CS-THG-Q10009

G10

5.556

95%

Polished

CS-THG-Q10010

G10

5.953

95%

Polished

CS-THG-Q10011

G10

6.35

95%

Polished

CS-THG-Q10012

G10

6.747

95%

Polished

CS-THG-Q10013

G10

7.144

95%

Polished

CS-THG-Q10014

G10

7.938

95%

Polished

CS-THG-Q10015

G10

8.5

95%

Polished

CS-THG-Q10016

G10

8.731

95%

Polished

CS-THG-Q10017

G10

9.525

95%

Polished

CS-THG-Q10018

G10

10

95%

Polished

CS-THG-Q10019

G10

11

95%

Polished

CS-THG-Q10020

G10

11.113

95%

Polished

CS-THG-Q10021

G10

6.35

95%

Polished

CS-THG-Q10022

G10

10

95%

Polished

CS-THG-Q10023

G10

11.1125

95%

Polished

Item

Grade

Purity

Subject

CS-THG-Q001

1.5-2

99%

Unpolish

CS-THG-Q002

3-3.5

99%

Unpolish

CS-THG-Q003

5

99%

Unpolish

CS-THG-Q004

5.5

99%

Unpolish

CS-THG-Q005

6.7-7

99%

Unpolish

CS-THG-Q006

7-7.5

99%

Unpolish

CS-THG-Q007

8.5-9

99%

Unpolish

CS-THG-Q008

11.5-12

99%

Unpolish

CS-THG-Q009

15-15.5

99%

Unpolish

CS-THG-Q010

19-20

99%

Unpolish

CS-THG-Q011

26.5-27

99%

Unpolish

CS-THG-Q012

32-.5-33

99%

Unpolish

CS-THG-Q013

40

99%

Unpolish

CS-THG-Q014

44

99%

Unpolish

CS-THG-Q015

60

99%

Unpolish

Sic Balls Test Standards

1.Silicon Carbide Bearing Balls should meet ASTM F2288-17 Standard Specification for Bearing Grade Silicon Carbide.

2.This standard specifies the requirements for bearing grade silicon carbide, including chemical composition, physical properties, and dimensional tolerances.

3.The standard also outlines the requirements for inspection and test methods, as well as marking and packaging.

OEM Service

Packing & Delivery

Why Choose Us

As a professional industrial ceramic supplier, we have a series of advantages that guarantee our market share in the international trade market.

1.Reliable quality control, complete specifications, support customization of non-standard products.

2.Professional and committed service team.

3.Multiple protection of packaging, secure and reliable.

4.Highly efficient delivery channel, safe and rest-assured.

FAQ

1.Q: What is a silicon carbide bearing ball?

A: A silicon carbide bearing ball is a highly durable, ultra-hard ball used in bearings that require low friction and high wear resistance. They are more resistant to wear and corrosion than steel or ceramic balls, making them ideal for use in hostile environments. Silicon carbide bearing balls also provide excellent thermal conductivity, making them suitable for high temperature applications.

2.Q: What are the advantages of using silicon carbide bearing balls?

A: Silicon carbide bearing balls offer superior performance in comparison to steel or ceramic bearing balls. They are harder, lighter, and more wear resistant than steel or ceramic, and can withstand higher temperatures. Additionally, silicon carbide bearing balls have a much lower coefficient of friction than their counterparts, resulting in smoother, more efficient operation.

Ampoules for TGA and TGA-DTA measurements equivalent to Netzsch GB461177

Ampoules for TGA and TGA-DTA measurements equivalent to Netzsch GB461177

GB461177 Netzsch Fused silica parts .csceramic provides all thermal analysis consumables

95 μl Alumina crucible equivilent to Netzsch J1560182 for STA 2500 Regulus

95 μl Alumina crucible equivilent to Netzsch J1560182 for STA 2500 Regulus

Manufacturer for Netzsch crucibles and sample cups. Netzsch Instruments good alternative DSC sample pans.

High-Temp Resistant Ceramic Ring for Fiber Laser Cutters

High-Temp Resistant Ceramic Ring for Fiber Laser Cutters

The ceramic ring for laser cutting machines, resistant to high temp & corrosion, focuses, collimates, transmits laser beams, protecting the head from damage & contamination.

Fused Silica Crucible Quartz Ceramic Crucibles for Melting Gold

Fused Silica Crucible Quartz Ceramic Crucibles for Melting Gold

Fused quartz ceramic crucibles are mainly used for the melting of platinum, gold,and other high-temperature alloys,with high purity,corrosion resistance, and strong thermal shock resistance. Available in various shapes and sizes.

Disposable Porcelain boats 528-053 Alpha AR8053 Eltra 88600-0011/90160

Disposable Porcelain boats 528-053 Alpha AR8053 Eltra 88600-0011/90160

LECO 528-053 Ceramic Combustion Boat, Alpha AR8053 Eltra 90160. Disposable porcelain boats. Manufacturer of LECO Ceramic Combustion boats.

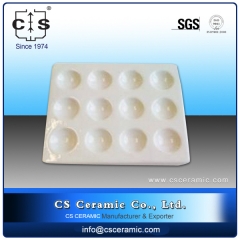

4 Hollows Porcelain Spotting Color Plates Labware For Testing

4 Hollows Porcelain Spotting Color Plates Labware For Testing

1.Used for PH tests or qualitative analysis of solutions for precipitate formatio. 2. Resist temperature is to be 1050 degrees centigrade.

NICKEL PANS equivalent to Shimadzu 201-53102-84 for DSC-60 series, DSC-60 plus series, TGA-50 series, TGA-51 series, DTG-60 series, and DTA-50 instruments

NICKEL PANS equivalent to Shimadzu 201-53102-84 for DSC-60 series, DSC-60 plus series, TGA-50 series, TGA-51 series, DTG-60 series, and DTA-50 instruments

for Shimadzu TDA DSC and TGA measurements. Manufacturer for Shimadzu crucibles and sample cups TG/DTG sample pan/tray. Shimadzu Instruments good alternative DSC sample pans.

900μl Alumina large sample pans crucibles w/lid equivalent to ME-51119960 for Mettler Toledo (Sample pans)

900μl Alumina large sample pans crucibles w/lid equivalent to ME-51119960 for Mettler Toledo (Sample pans)

ME-51119960 Alumina crucibles sample pans for Mettler DSC and SDTA measurements. Manufacturer for Mettler Toledo crucibles and sample pans. DSC sample test trays for dsc measurement.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522