Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read Moreitem no. :

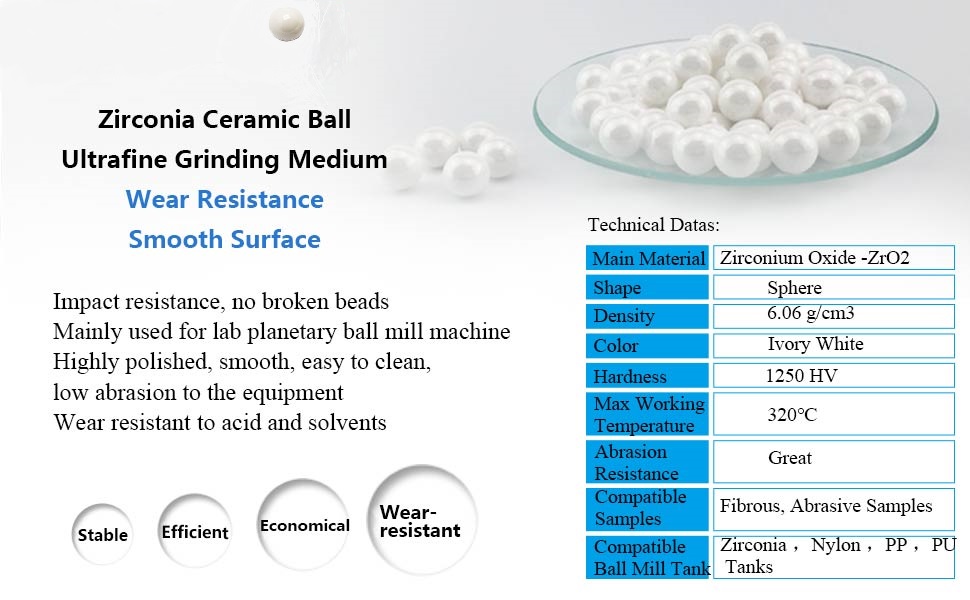

CS-YHG-Q003:

ChinaColor :

WhitePort :

Any ports of Chinalead date :

1-7 daysMaterial : Zirconia ceramic

Purity : 95%

Shape : Round

1. Zirconia balls are highly durable and have a practically higher abrasion and corrosion resistance than other materials.

2. These balls are also much more stalls in temperature changes and have superior physics strength.

3. They are very precise and can be manufactured to really tight tolerances.

4. zirconium dioxide balls have a very low undefined of rubbing and are excellent for high-speed applications.

5. They are also excellent electrical insulators, making them ideal for utilise in high-voltage applications.

6. Zirconia balls are too non-magnetic and non-conductive, making them ideal for use in medical and physical phenomenon applications.

7. They are also extremely lightweight, making them ideal for applications where weight is an issue.

8. Finally, these balls are very cost-effective and can be used in a wide straddle of applications.

Zirconia balls are used in a wide variety of applications.

1.They are used in valves, pumps, bearings, and other mechanical components.

2.They are also used in medical and cosmetic applications, such as dental implants, prosthetics, and cosmetics.

3.Zirconia balls are also used to manufacture cameras and lenses, as well as to make grinding and polishing media.

Technical Parameters

|

Chemical Component |

Percentage |

|

ZrO2 |

95%±0.2 |

|

Y2O3 |

5%±0.2 |

|

Physical Properties |

Value |

|

density (g/cm3) |

>=5.95 |

|

bulk density (kg/L) |

3.5 (Φ5mm) |

|

hardness (GPa) |

>11 |

|

modulus of elasticity (GPa) |

200 |

|

thermal conductivity coefficient (W/m.K) |

3 |

|

thermo-expansion coefficient (/℃) |

9.6×10-6 |

|

crushing strength (KN) |

>1.5 (Φ2mm), >=20 (Φ7mm) |

|

fracture toughness (MPam1/2) |

8 |

|

Spec. No. |

Diameter (mm) |

Purity (%) |

|

CS-YHG-Q001 |

0.6-0.8 |

95 |

|

CS-YHG-Q002 |

0.8-1.0 |

95 |

|

CS-YHG-Q003 |

1.0-1.2 |

95 |

|

CS-YHG-Q004 |

1.2-1.4 |

95 |

|

CS-YHG-Q005 |

1.4-1.6 |

95 |

|

CS-YHG-Q006 |

1.6-1.8 |

95 |

|

CS-YHG-Q007 |

1.8-2.0 |

95 |

|

CS-YHG-Q008 |

2.0-2.2 |

95 |

|

CS-YHG-Q009 |

2.2-2.4 |

95 |

|

CS-YHG-Q010 |

2.4-2.6 |

95 |

|

CS-YHG-Q011 |

2.6-2.8 |

95 |

|

CS-YHG-Q012 |

2.8-3.0 |

95 |

|

CS-YHG-Q013 |

3.0-3.2 |

95 |

|

CS-YHG-Q014 |

3.2-3.4 |

95 |

|

CS-YHG-Q015 |

4.0-4.3 |

95 |

|

CS-YHG-Q016 |

4.8-5.3 |

95 |

|

CS-YHG-Q017 |

5.8-6.3 |

95 |

|

CS-YHG-Q018 |

8 |

95 |

|

CS-YHG-Q019 |

10 |

95 |

|

CS-YHG-Q020 |

12 |

95 |

|

CS-YHG-Q021 |

15 |

95 |

|

CS-YHG-Q022 |

20 |

95 |

|

CS-YHG-Q023 |

0.4-0.6 |

95 |

|

CS-YHG-Q024 |

0.28-0.35 |

95 |

|

CS-YHG-Q025 |

0.22-0.28 |

95 |

|

CS-YHG-Q026 |

0.18-0.23 |

95 |

|

CS-YHG-Q027 |

0.12-0.18 |

95 |

|

CS-YHG-Q028 |

0.08-0.12 |

95 |

|

CS-YHG-Q029 |

5 |

95 |

|

CS-YHG-Q030 |

6 |

95 |

|

CS-YHG-Q031 |

7 |

95 |

|

CS-YHG-Q032 |

17 |

95 |

|

CS-YHG-Q033 |

25 |

95 |

|

CS-YHG-Q034 |

30 |

95 |

|

CS-YHG-Q035 |

40 |

95 |

|

CS-YHG-Q036 |

50 |

95 |

1. Confirm whether zirconia beads are suitable

The selection of zirconia beads is a key step. Zirconia beads have different hardness, surface smoothness, particle size distribution, abrasion, chemical properties (do not react with materials) and other characteristics. Therefore, appropriate zirconia beads should be selected according to the type and target particle size of the materials you grind and in combination with the target particle size of grinding.

2. Pre-grinding

When using zirconia beads for the first time, it is necessary to put the zirconia beads in the slurry with a certain viscosity for pre-grinding for 30 minutes. If the slurry concentration is relatively low, the rotation speed should be reduced, and then the time should not exceed 15 minutes.

3. Cleaning

When grinding paint, it is better to clean zirconia beads with resin. If solvent is needed, reduce the rotation speed, and the time should not exceed 10 minutes. It is recommended to clean zirconia beads intermittently, and then shut down and restart the machine after a period of time.

4. Make up the ball

After grinding for a period of time, zirconia beads will collide with each other, which will lead to abrasion of zirconia beads. Therefore, after using for a period of time, some zirconia beads need to be added as a supplement. Note that the broken zirconia beads should be screened off with a sieve before supplement, and then put in zirconia beads with the same weight as the broken zirconia beads.

5. Cases when more beads need to be supplemented

If the grinding time needs to be extended or the grinding fineness can not reach the desired effect when the grinding fineness requirements remain unchanged, a certain amount of zirconia beads need to be added.

Zirconia Ball Test Standard

The Zirconia balls screen monetary standard is an international standard for the quality evaluation of Zirconia balls.

1.The standard is used to judge the physical and chemical properties of zirconium oxide balls and to ensure their public presentation and safety.

2.The monetary standard covers aspects such as size, hardness, surface finish, tolerance, and chemical composition.

3.The standard also outlines procedures for testing the properties of Zirconia balls and provides a basis for comparison with strange synonymous materials.

4.The test standard is regularly reviewed and updated to ensure it stiff upward to date with the latest technology.

OEM Service

We

offer customized products according to customer’s needs. Please

provide to us with the following parameters when you need a

customized product.

1: The name of the product that needs

grinding.

2: Grinding method (dry grinding/wet grinding).

3:

Grinder size/model.

4: Feed size and discharge size.

1.We provide zirconia grinding beads that have uniform microstructure from inside to outside.

2.We have special ways of controlling product microstructure crystallizing phase.

3.The bead’s microstructure is almost the same as that of Japan TOSOH company similar product.

4.Our products are widely used in aerospace, mining machinery, elevators, power, paper, laboratory, non-ferrous metal processing, electronic processing, textile machinery and other industries.

FAQ

1.Q: What are zirconia pave balls?

A: Zirconia pave balls are small metallic spheres that are used in jewelry making and other decorative arts, such as fashion accessories. They are made from zirconia, a crystalline form of the element zirconium, which is a white metal with a high melting point and excellent thermal and electrical conductivity. Zirconia pave balls have a smooth, glossy finish and can be found in a variety of colors, including white, pink, blue, yellow, and black.

2.Q: What are the benefits of using zirconia pave balls?

A: Zirconia pave balls are an excellent choice for jewelry and other decorative projects because they are light, durable, and cost-effective. The balls are also resistant to scratches and other damage and can be set in sterling silver or gold-plated settings for an extra touch of glamour. Additionally, the balls have a unique and eye-catching look that can help to create stunning designs.

3.Q: How are zirconia pave balls used?

A: zirconium dioxide pave balls are usually typeset in sterling silver medal or gold-plated settings, providing a unusual and eye-catching look for jewellery pieces. They are nonsuch for adding sparkle and texture to whatever patch and put up be used in a variety of ways, from creating earrings and necklaces to creating bracelets, rings, and other pieces.

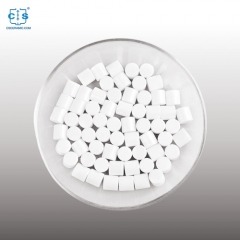

Cylinder Zirconium Oxide Grinding Media Ball

Cylinder Zirconium Oxide Grinding Media Ball

Zirconia grinding ball is a high-performance, durable and cost-effective grinding media designed for use in ball mills, vibratory mills and other milling systems.

Zirconia Grinding Balls High Density Media Beads

Zirconia Grinding Balls High Density Media Beads

zirconia grinding balls are ultra-wear-resistant, high-density ceramic beads ideal for fine grinding and dispersion of high-hardness materials. With high strength, hardness, and fracture toughness, they offer excellent temperature resistance, corrosion resistance, and non-magnetic conductivity.

75mm Porcelain Ash Volatile Crucible of Thermal Instrument Accessories

75mm Porcelain Ash Volatile Crucible of Thermal Instrument Accessories

1.Porcelain Ash Volatile Crucible as Thermal Instrument Accessories 2.Good thermal shock,no easy to crack. 3.High slip casting density

Alumina Ceramic Substrate Sheet/Plate

Alumina Ceramic Substrate Sheet/Plate

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Small Alumina Ceramic Rods for Textile Machine

Small Alumina Ceramic Rods for Textile Machine

Alumina rods/tubes are lightweight and durable, making them suitable for use in a variety of textile applications. Available in a variety of sizes and shapes.

Silicon Carbide Lined Canned Pump Sealless Design for Leak-Free Operation

Silicon Carbide Lined Canned Pump Sealless Design for Leak-Free Operation

The Silicon Carbide Lined Canned Pump, a sealless design with pump and motor enclosed in a pressurized vessel filled with pumped media and powered by an electric cable assembly, eliminates rotating shaft seals for complete leak-free operation.

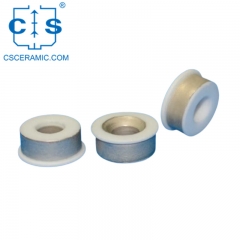

High-Temp Resistant Ceramic Ring for Fiber Laser Cutters

High-Temp Resistant Ceramic Ring for Fiber Laser Cutters

The ceramic ring for laser cutting machines, resistant to high temp & corrosion, focuses, collimates, transmits laser beams, protecting the head from damage & contamination.

High-Temp Resistant Si3N4 Ceramic Crucible with Lid for Heating Melting & Chemical Analysis

High-Temp Resistant Si3N4 Ceramic Crucible with Lid for Heating Melting & Chemical Analysis

The Si3N4 ceramic crucible, sintered in pressurized nitrogen, resists high temps, acids, alkalis, ideal for heating, melting, & high-temp chemical analysis.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522