Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read Moreitem no. :

CS-AlN-AC001Material : Aluminum Nitride

Shape : Cylindrical

Cylindrical Aluminum Nitride Crucible Advantages:

1. Cylindrical aluminum nitride crucible can endure high temperatures, making them ideal for melting and heat processing applications.

2. It is highly resistant to chemical corrosion.

3. Excellent thermal conductor, which helps in the equal distribution of heat during the manufacturing process.

4. It has a low density, making them lightweight and easy to handle.

5. Very durable and can be used repeatedly. This reduces the need for frequent replacements, which in turn lowers manufacturing costs.

6. It is a high-purity material that does not contaminate the materials it holds. This makes it an ideal choice for manufacturing semiconductor devices and other applications that require clean and pure materials.

Cylindrical Aluminum Nitride Crucible Description:

1. Aluminum nitride crucibles are used to hold and contain materials that are subjected to high temperatures in the laboratory or industrial settings.

2. The Aluminum Nitride Crucible is made of pure aluminum nitride material that ensures high thermal conductivity, excellent resistance to thermal shock, and high mechanical strength.

3. This crucible provides a stable and uniform heating surface that is ideal for experiments that require precision and accuracy.

4. Aluminum nitride crucibles can be manufactured in various shapes and sizes.

Usage of Aluminum Nitride Crucibles:

1.Aluminum nitride ceramics will react chemically with inorganic acids and strong bases, water and other liquids and slowly dissolve with them, so it cannot be directly immersed in such substances for use. But aluminum nitride can resist the corrosion of most molten salts, including chlorides and cryolite(Na3AlF6).

2.Due to the aluminum nitride crucible has small bottom, it usually needs to be placed on a clay triangle when heated, and cannot be directly contacted with metal or wooden bearing after strong heating. It cannot be cooled suddenly after heating, and needs to be cooled naturally on the clay triangle, or gradually cooled on the asbestos gauze, and finally taken out with a crucible tong.

3.Stirring the substance until nearly evaporated, then turn off the heat, and steam it with the remaining heat.

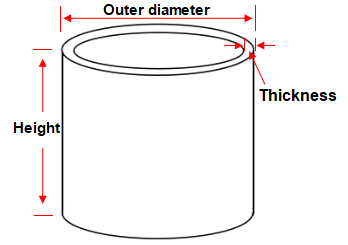

Cylindrical Aluminum Nitride Crucible Size details:

| Cylindrical Aluminum Nitride Ceramic Crucible | |||||

| Item NO. |

Outer Diameter

(mm)

|

Height

(mm)

|

Thickness

(mm)

|

Purity | coefficient of thermal conductivity |

| CS-AIN-AC001 | 5-150 | 5-150 | 3-10 | 99% | 170-220W/m.k |

| CS-AIN-AC002 | 16 | 56 | 3 | 99% | ≥170W/m.k |

| CS-AIN-AC003 | 17 | 40 | 3 | 99% | ≥170W/m.k |

| CS-AIN-AC004 | 19 | 35 | 3 | 99% | ≥170W/m.k |

| CS-AIN-AC005 | 19 | 58 | 3 | 99% | ≥170W/m.k |

| CS-AIN-AC006 | 20 | 30 | 3 | 99% | ≥170W/m.k |

| CS-AIN-AC007 | 20 | 40 | 3 | 99% | ≥170W/m.k |

| CS-AIN-AC008 | 20 | 50 | 3.5 | 99% | ≥170W/m.k |

| CS-AIN-AC009 | 22 | 36 | 3.5 | 99% | ≥170W/m.k |

| CS-AIN-AC010 | 22 | 25 | 3.5 | 99% | ≥170W/m.k |

| CS-AIN-AC011 | 23 | 60 | 3.5 | 99% | ≥170W/m.k |

| CS-AIN-AC012 | 25 | 25 | 4 | 99% | ≥170W/m.k |

| CS-AIN-AC013 | 25 | 30 | 4 | 99% | ≥170W/m.k |

| CS-AIN-AC014 | 25 | 60 | 4 | 99% | ≥170W/m.k |

| CS-AIN-AC015 | 30 | 28 | 4 | 99% | ≥170W/m.k |

| CS-AIN-AC016 | 30 | 30 | 4 | 99% | ≥170W/m.k |

| CS-AIN-AC017 | 35 | 30 | 4 | 99% | ≥170W/m.k |

| CS-AIN-AC018 | 47 | 13 | 4 | 99% | ≥170W/m.k |

| CS-AIN-AC019 | 60 | 105 | 5 | 99% | ≥170W/m.k |

| CS-AIN-AC020 | 88 | 150 | 5 | 99% | ≥170W/m.k |

| CS-AIN-AC021 | 100 | 100 | 6 | 99% | ≥170W/m.k |

| CS-AIN-AC022 | 110 | 110 | 6 | 99% | ≥170W/m.k |

| CS-AIN-AC023 | 110 | 150 | 6 | 99% | ≥170W/m.k |

| CS-AIN-AC024 | 115 | 110 | 6 | 99% | ≥170W/m.k |

| CS-AIN-AC025 | 115 | 155 | 6 | 99% | ≥170W/m.k |

| CS-AIN-AC026 | 120 | 120 | 7 | 99% | ≥170W/m.k |

| CS-AIN-AC027 | 125 | 150 | 7 | 99% | ≥170W/m.k |

| CS-AIN-AC028 | 130 | 130 | 7 | 99% | ≥170W/m.k |

| CS-AIN-AC029 | 135 | 30 | 7 | 99% | ≥170W/m.k |

| CS-AIN-AC030 | 135 | 110 | 7 | 99% | ≥170W/m.k |

| CS-AIN-AC031 | 140 | 140 | 8 | 99% | ≥170W/m.k |

OEM/ODM is acceptable. Your goods will be produced exactly according to your drawings or inquiry

Properties:

| Material Properties of AIN Ceramic | ||||||

| Property Sort | Characteristic | Unit | Property Index | |||

| AN170 | AN200 | AN220 | ||||

| Basic Property | Color | - | Grey | Grey | Beige | |

| Water absorption | % | 0 | 0 | 0 | ||

| Volume density | g/cm3 | ≥3.30 | ≥3.30 | ≥3.26 | ||

| Surface roughness | um | 0.1~0.6 | 0.1~0.6 | 0.1~0.6 | ||

| Camber | (length ‰) | ≤2‰ | ≤2‰ | ≤2‰ | ||

| Thermal Property | Thermal conductivity (20℃) | W/m.k | ≥170 | ≥200 | ≥220 | |

| Coefficient of thermal expansion | (20℃~300℃) | (*10-6/℃) | 4.6 | 4.6 | 4.5 | |

| (40℃~800℃) | 5.2 | 5.2 | 5.2 | |||

| Mechanical Property | Bending strength | MPa | ≥450 | ≥300 | ≥200 | |

| Modulus strength | GPa | 320 | 310 | 310 | ||

| Moh's hardness | - | 8 | 8 | 8 | ||

| Electrical Property | Dielectric strengh | KV/mm | ≥17 | ≥16 | ≥15 | |

| Volume resistivity | Ω.cm | ≥1014 | ≥1014 | ≥1013 | ||

| Dielectric constant | - | 9 | 8.6 | 8.5 | ||

| Dielectric loss | *10-4 | 2.98 | 2 | 2 | ||

Cylindrical Aluminum Nitride Crucible Applications:

1. Cylindrical aluminum nitride crucibles can be used in the production of semiconductors.

2. The high thermal conductivity and resistance to chemical and thermal shock of the aluminum nitride crucible make it a good option for chemical synthesis.

3. Suitable for the melting of metals and alloys.

4. It is commonly used in crystal growing applications.

5. Powder metallurgy involves the manufacturing of metal powders and the production of parts using these powders.

6. It can be used in sample preparation for microscopy, particularly in electron microscopy where a high vacuum and high temperature environment is required.

FAQ

Q1. What information should we supply to get a quote?

Please offer the specification of aluminum nitride crucible, such as shape, dimension, quantity, application etc.

Q2. What are the benefits of using the aluminum nitride crucible?

The aluminum nitride crucible offers a high melting point, making it suitable for high-temperature applications. Additionally, it has excellent thermal shock resistance, high thermal conductivity, and good chemical resistance.

Q3. What materials can be heated or melted in an aluminum nitride crucible?

Aluminum nitride crucibles can be used to heat or melt a wide range of materials, including metals, ceramics, and semiconductors. They are particularly suited for the production of high-purity alloys, such as rare earth metals and their alloys.

Q4. What is the lead time for the aluminum nitride crucible?

The lead time is dependent on the size and quantity required. Please contact us for more infor.

How to clean conical aluminum nitride crucible:

1. When handling crucibles, protective gloves and glasses should be worn.

2. Use a soft cloth to wipe away any residue from the crucible.

3. Add warm water and mild detergent to the crucible.

4. Use a soft bristle brush to scrub the crucible and remove any stubborn residue.

5. Clean the crucible with water.

Quality testing standards:

1. Visual inspection of the crucible for any signs of damage or irregularities.

2. Measurement of the length, width, and thickness of the crucible to check for accuracy.

3. Checking for any leaks or pinhole defects in the crucible.

4. Verification of the material and chemical composition of the crucible.

Packing way:

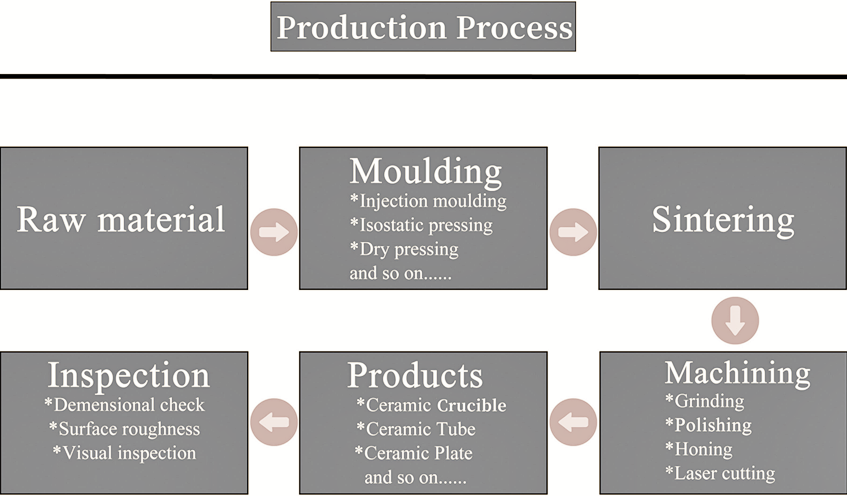

Production Process:

Why Choose us?

1. We supply personalized and customized services to contact your personal needs.

2. We are experienced professionals with a good record of success.

3. We provide superior client service and promptly respond to all inquiries.

4. We provide militant prices and strive to ensure that your funds receive the best value.

5. We use the latest technologies and tools to ensure that your project is completed to the highest standards.

Square High Thermal Conductivity AlN Aluminum Nitride Ceramic Crucible

Square High Thermal Conductivity AlN Aluminum Nitride Ceramic Crucible

Square aluminum nitride ceramic crucible can be better applied in chemical experiments,it is known for its high thermal conductivity and remarkable electrical insulation properties.Available in a variety of sizes.

ARC Conical Aluminum Nitride Ceramic Crucible High Thermal Conductivity AlN Crucibles

ARC Conical Aluminum Nitride Ceramic Crucible High Thermal Conductivity AlN Crucibles

Aluminum nitride ceramic crucible has superior temperature resistance as well as strong acid and alkali resistance,which can be better applied in chemical experiments.Available in a variety of sizes and shapes.

Smooth Wall Tin Capsule D8*20mm 502-167

Smooth Wall Tin Capsule D8*20mm 502-167

Tin capsules are routinely used to analyze polymers, soils, coal, dry dairy products, plant leaves, paper, textiles, calibration standards, and many organic and pharmaceutical products.

High-Performance Si3N4 Ceramic Ball Bearing

High-Performance Si3N4 Ceramic Ball Bearing

The Silicon Nitride Bearing is a high-performance option, featuring lightweight design, ideal for harsh environments & high-speed applications.

Titanium seals equivalent to PE B0185054 for PE B0182903

Titanium seals equivalent to PE B0185054 for PE B0182903

CSCERAMIC is Thermal analysis consumables source manufacturer

30μl Reusable High Pressure Stainless Steel crucible with lid/seal ME-51140404 for Mettler Toledo

30μl Reusable High Pressure Stainless Steel crucible with lid/seal ME-51140404 for Mettler Toledo

30μl ME-51140404 High pressure steel crucible with lid/seal, without pin. Manufacturer of Thermal analysis crucible consumables for Mettler Toledo DSC&TGA equipment.

Alumina Ceramic Flange for Precision Machining

Alumina Ceramic Flange for Precision Machining

Alumina ceramic flange is a lightweight, durable and strong flange that can withstand extreme temperatures and pressures without degrading or corroding.Available in various sizes and shapes.

Transparent 99.98% Quartz Glass Tubes with Both Ends Open

Transparent 99.98% Quartz Glass Tubes with Both Ends Open

Quartz glass tubes have thermal and chemical resistance, optical clarity, and mechanical strength. Available in a variety of lengths, diameters, and wall thicknesses to meet different application requirements.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522