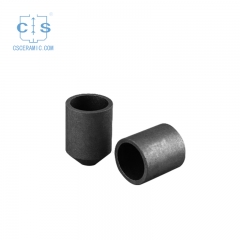

Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read MoreCeramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

item no. :

CS001Suitable for : Leco Bruker Eltra Horiba Alpha

Material : ceramic

Part NO : 528-018 AR3818 90150 905.200.380.001

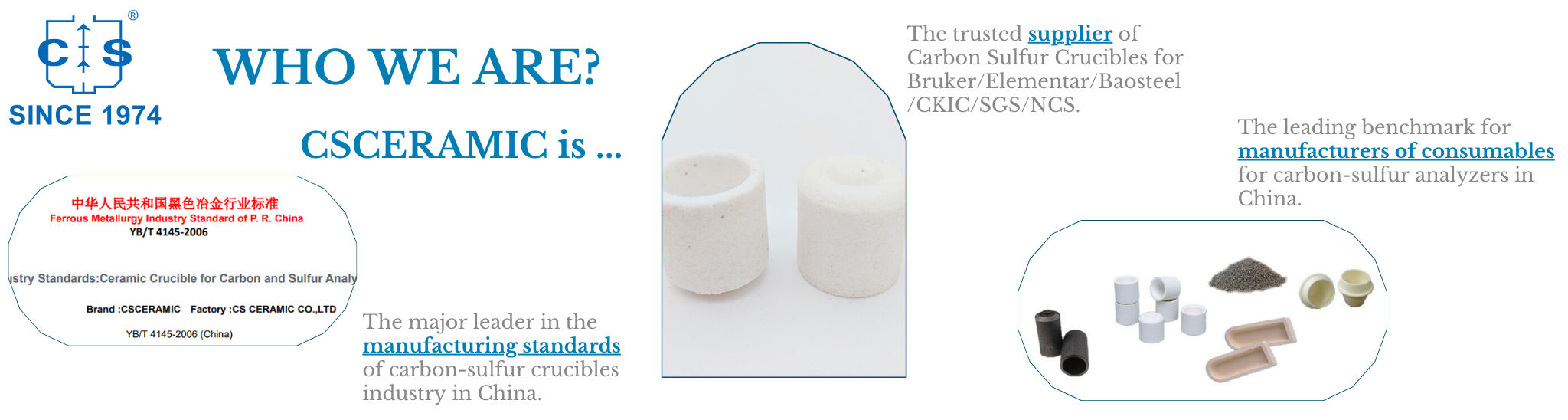

We are...

The trusted supplier of Carbon Sulfur Crucibles for Bruker/Elementar/Baosteel/CKIC/SGS/NCS.

And...

The major leader in the manufacturing standards of carbon-sulfur crucibles industry in China.

Also...

The leading benchmark for manufacturers of consumables for carbon-sulfur analyzers in China.

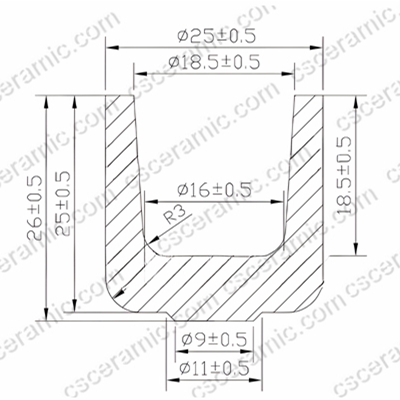

Dimension |

25mm*25mm |

Main Material |

Fused Quartz |

Blank Value of Carbon & Sulfur |

C%<3ppm, S%<2ppm |

Max. Working Temperature |

1400°C |

Max. Temperature of Rapid Changes |

Up to 350°C |

Max. Physical Pressure |

45,000psi |

Product Quantity |

1000PSC/CTN |

Product Sample Service |

Free Offer |

Compatible Instruments

Consumables No.

Bruker G4 Icarus CS

Eltra CHS580/CHS580A

Eltra CS-2000

Eltra CS800

Eltra Helios

Horiba EMIA-320V2/920V2

Horiba EMIA820V/320V/220V

LECO® CS125/225

LECO® CS200/C200/S200/WC200

LECO® CS230

LECO® CS244/344/IR212/232

LECO® CS400/C400/S400

LECO® CS444/IR412/432

LECO® CS600

LECO® CS744

LECO® CS844

LECO® WR112

Bruker® W-N009250423/Q105054

Eltra® 90148/90149/90150/90152

LECO® 528-018

LECO® 002-308

LECO® 002-309

Horiba® 905.200.380.001

Horiba® 905.200.380.001 AN

Horiba® 1100132671

Elementar® 905.200.380.001 AN

SerCon® SC0893

Alpha® AR3818

Blog 3:Key points of Super Low Carbon Content Analyzing by High Frequency Infrared Carbon Sulfur Analyzer

|

a) |

|

|

Q: |

What is a carbon sulfur crucible? |

|

A: |

A carbon paper sulfur melting pot is a technical watercraft used in carbon/sulfur analysis. It is made of a carbon-sulfur alloy and is designed to hold out high temperatures. |

|

b) |

|

|

Q: |

What is the resolve of a carbon sulphur crucible? |

|

A: |

The resolve of a carbon sulfur crucible is to accurately measure the add up of carbon and sulfur submit in a sample. It is used in a variety of industries, including anoint and gas, metalworking, and chemical processing. |

|

c) |

|

|

Q: |

What typewrite of material is old to make a carbon sulfur crucible? |

|

A: |

Carbon sulphur crucibles are typically made from a carbon-sulfur alloy. This alloy is premeditated to resist high temperatures and provide accurate results. |

|

d) |

|

|

Q: |

How often should a carbon sulphur crucible be replaced? |

|

A: |

Carbon sulfur crucibles should be replaced regularly to ensure precise results. It is recommended that they be replaced after every 100 samples or every 6 months, whichever comes first. |

|

e) |

|

|

Q: |

What type of sustainment is necessary for a carbon sulfur crucible? |

|

A: |

Sustentation for a carbon sulfur melting pot should include regular cleanup and inspection. The melting pot should also be kept away from wet and undefined chemicals. |

|

f) |

|

|

Q: |

What safety precautions should be taken when using a carbon sulfur crucible? |

|

A: |

When using a carbon sulphur crucible, refuge precautions should include wear safety glasses, gloves, and a face mask. It is also important to ensure that the crucible is not overfilled and that the sample is not heated to an excessive temperature. |

Reference Picture

Item Name

Reference Picture

Item Name

Tungsten accelerator

Graphite Crucible 776-247

Iron chip accelerator

Graphite Crucible 775-431

Tungsten/Tin Accelerator

Graphite Crucibles 775-433

Ceramic crucible cover

C/S Crucibles 23*23 24*24 26*26mm

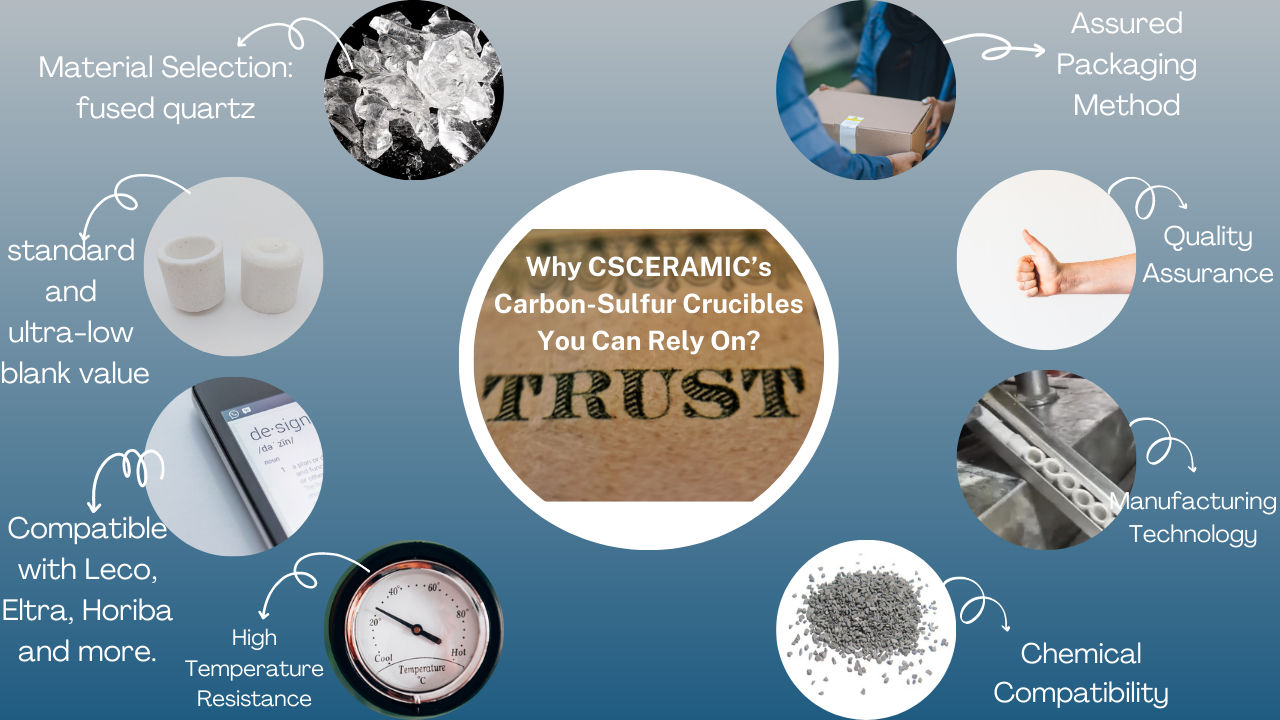

Our crucibles are made from chemically inert high-quality ceramic materials, offering excellent thermal stability and corrosion resistance. The primary material used is fused quartz. The selected materials can withstand high temperatures and corrosive environments during carbon-sulfur analysis processes.

Our carbon-sulfur crucibles are available in two types: standard blank value(C% < 5ppm, S% < 5ppm) and ultra-low blank value (C%< 3ppm, S%< 2ppm). The crucibles are free from impurities, ensuring accuracy in carbon-sulfur measurements. Strict quality control measures are implemented during the manufacturing process to achieve the required levels of purity.

Our crucibles are designed to perfectly fit models of carbon-sulfur analyzers from brands such as Leco, Eltra, Horiba, and others.

The carbon-sulfur ceramic crucibles possess high temperature resistance and can withstand the high-temperature heating required during the analysis process. The crucibles can maintain their structural integrity and chemical stability without deformation or damage at temperatures as high as 1400°C.

The carbon-sulfur ceramic crucibles are chemically compatible with the substances and reagents used in carbon-sulfur analysis. They can resist reactions or interactions with common acids, oxidizers, and reducing agents, preserving the integrity of the samples and ensuring accurate results. Our crucibles have successfully passed compatibility tests, demonstrating their resistance to chemical erosion.

The production of ceramic crucibles involves precise control of manufacturing parameters such as temperature, pressure, and drying conditions through pressing and shaping processes. This ensures consistent quality and dimensional accuracy.

We implement stringent quality control measures during the manufacturing process to ensure the reliability and performance of our crucibles. This includes inspection and testing of raw materials, process monitoring, dimension checks, and performance evaluations.

| Testing of Finished Ceramic Crucibles | |

| 1. |

Check the crucible for any cracks or other damage. |

| 2. |

Ensure that the crucible is properly plastered to prevent contamination. |

| 3. |

Verify that the crucible is made of the correct material and of the undefined size for the analyzer. |

| 4. |

Ensure that the melting pot is able to withstand the temperatures necessity for the analysis. |

The packaging method has undergone repeated testing to minimize breakage and damage, ensuring that the crucibles are delivered to customers in the best possible condition.

1 .Crucible shall be packed with tin foil or pure aluminum white paper, and the minimum packing unit shall be 10 pieces for each roll. Rolls should be put into paper packing cases with plastic film as inner liner, and should be arranged in sequence with corrugated paper as the interval between layers, for each case, total quantity should be 1000 pieces.

2 .If the buyer has special requirements for packaging, welcome to contact with our sales.

Other Additional Information You May Be Interested in...

1. Wear protective gloves and safety goggles when handling the crucible.

2. Place the melting pot in a undefined of warm water and add a few drops of detergent.

3. Use a easy brush to remove some residue from the crucible.

4. Wash the crucible with strip irrigate and dry it with a easy cloth.

Besides raw material and fabrication process, crucible baseline may also from absorption. Before using, influence of water, SO2 and CO2 to analyzing result should be avoided. For this purpose, two methods below are recommended.

Method 1, put carbon sulfur ceramic crucible in high temperature furnace, raise the temperature to 1200℃ and burn it for 2 hours, then take it out and get cooled, put into desiccator for demand (preservation time no longer than 4 hours)

Method 2, put carbon-sulfuric analysis crucible in tube-type crucible furnace, induce pure oxygen (purity 99.% or higher), and burn it no less than 1 hour at 1200℃.

Note: Products without pretreatment can be used directly for occasion that normal carbon sulfur blank value (10ppm) is acceptable.

A.1 reagents

A.1.1 pure iron flux: the particle size is less than 1.25mm, and mass fraction of both carbon and broken iron are less than 0.0005%.

A.1.2 vanadium pentoxide: purely analyzed, put it into a muffle furnace at 600℃ for 2 hours before using, and cool it in a dryer for reserve.

A.1.3 tungsten flux: the particle size is 0.4~0.8mm, and mass fraction of sulfur and sulfur are less than 0.001% and 0.0005% respectively.

A.1.4 ceramic crucible: use a ceramic crucible of good quality, burn it 4 hours at 1200℃ in a muffle furnace before using, then cool it overnight in the furnace and take it out after cooling down to room temperature in the dryer for reserve.

A.1.5 oxygen: high purity (higher than 99.5%)

A.2 instruments

A2.1 high frequency infrared sulfur analyzer: sensitivity 0.00001%

A.3 steps of analysis

A.3.1 Sample: Grind the "dedicated crucible for sulfur analysis" to less than 0.15mm with an agate mortar and roast it at 105-110℃ for 2h, then take it out and cool down to room temperature in a dryer for reserve.

A.3.2 render crucible (secondary crucible): Add 1 gram pure iron flux (A.1.1) and 1 gram tungsten flux (A.1.3) to a ceramic crucible treated as step A.1.4. Put the crucible in high-frequency induction furnace of infrared carbon crucible analyzer, aerate oxygen and heat it with analysis program. Take it down after the analysis is completed, after slightly cooled, then put it in a dryer (check and confirm no cracks) to cool it down to room temperature for reserve.

A.3.3 instrument calibration

Weigh standard sample 1.000 gram (C:0.00xx%, S:0.000xx% or C:0.000xx%, S: 0.0000xx%) and put it in render crucible. Add 1 gram pure iron flux (A.1.1) and 0.6 gram vanadium pentoxide (A.1.2) and input the mass value of weighed standard sample into the instrument mass compensator. Start analysis, repeat measurement for three times, and take the average value for instrument calibration.

A.3.4 measurement (baseline value of crucible material)

Accurately weigh 1.000 gram standard sample and put it in the bottom of render crucible and add 1 gram pure iron flux (A.1.1) and 0.6 gram vanadium pentoxide (A.1.2), and input the mass value of weighed standard sample into the instrument mass compensator. Complete the analysis, carbon and sulfur value given by the instrument is baseline value of the crucible material.

A.3.5 measurement (baseline value of crucible)

Take a pretreated ceramic crucible (or ceramic crucible without any pretreatment) and place it on an electronic balance. After getting the net weight, add 1 gram pure iron flux (A.1.1) and 0.6 gram vanadium pentoxide (A.1.2), and input mass value of 1.000 gram into the instrument mass compensator. Complete the analysis, carbon and sulfur value given by the instrument is baseline value of the crucible.

Large TGA Ceramic Crucible 529-047 621-331 20CC ALPHA AR9047 for LECO 701

Large TGA Ceramic Crucible 529-047 621-331 20CC ALPHA AR9047 for LECO 701

20 ml Large Ceramic Crucible 529-047 / 621-331 for LECO, Alpha AR9047. Manufacturer of TGA ceramic crucible for LECO TGA 500/501/601/701, MAC 400 / 500. TGA alumina crucible/pans for TGA-Thermogravimetric Analyzer analysis TGA measurement.

Ceramic Crucible Cover 10mm 528-043/619-880 Eltra 88600-001 905.130.200.001

Ceramic Crucible Cover 10mm 528-043/619-880 Eltra 88600-001 905.130.200.001

Crucible Cover With 10mm Hole LECO 528-043 528-040 Horiba 905.130.200.001. Manufacturer of cs crucible lid for LECO CS-400 CS-230 C4500 & C4501 Eltra CS800 for Carbon sulfur Analyzer.

Inner Graphite Crucible 775-431 775-892 Eltra 90180 for ONHp Elemental Analyzer

Inner Graphite Crucible 775-431 775-892 Eltra 90180 for ONHp Elemental Analyzer

LECO 775-431 Inner Graphite Crucible for applications requiring uniform crucible with 775-433 Crucibles. Eltra 90180 Horiba AR5431. Manufacturer of inner Graphite Crucible for LECO TC-400 TC-500 Ro-416, Eltra OH900 ON900.

Outer graphite crucibles 775-433 Eltra 90185 Alpha AR433 for ONHp Elemental Analyzer

Outer graphite crucibles 775-433 Eltra 90185 Alpha AR433 for ONHp Elemental Analyzer

LECO 775-433 outer Graphite Crucible for applications requiring uniform crucible with 775-431 and 775-892 Crucibles. Eltra 90185 Alpha AR433. Manufacturer of inner Graphite Crucible for LECO TC-400 TC-500 Ro-416, Eltra OH900 ON900.

Ceramic Combustion boats 529-204 529-204-250 for Carbon/Sulfur analyser

Ceramic Combustion boats 529-204 529-204-250 for Carbon/Sulfur analyser

LECO re-usable Ceramic Combustion boats 529-204 SerCon: SC0819, Manufacturer of Ceramic Combustion boats for LECO SC144. LECO consumables,Eltra consumables.

Regular Graphite crucible 776-247 ELTRA90190 ALPHA AR6247/AR053HD

Regular Graphite crucible 776-247 ELTRA90190 ALPHA AR6247/AR053HD

LECO 776-247 Regular Graphite crucible for typical nitrogen/oxygen analyses. Manufacturer of Graphite Crucible for LECO TC-400 TC-500 Ro-416, Eltra OH900 ON900, LECO /Eltra Analyzers Analyzer.

Graphite crucible Horiba 9052000200 for Horiba EMGA621W

Graphite crucible Horiba 9052000200 for Horiba EMGA621W

Horiba 9052000200 Graphite crucible. Manufacturer of Graphite Crucible for Horiba EMGA621W.

Graphite Outer Crucible Horiba 905.200.010.000/9052000100 Alpha AR1533

Graphite Outer Crucible Horiba 905.200.010.000/9052000100 Alpha AR1533

Horiba 905.200.010.000 Graphite Outer Crucible Alpha AR1533. Manufacturer of Graphite Crucible for Horiba EMGA-930.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522