Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

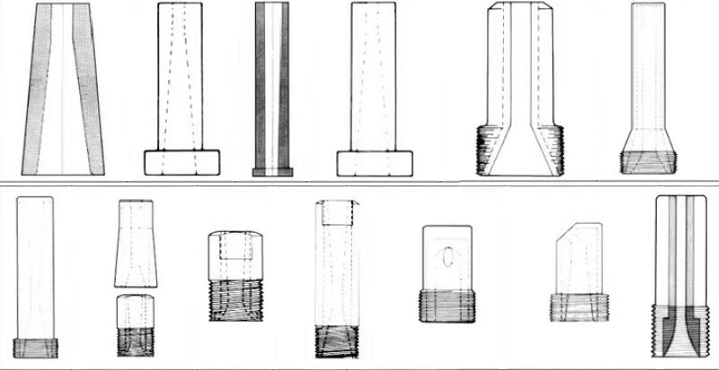

Read Moreitem no. :

CS-DHP-N1001Color :

WhitePort :

Any ports of Chinalead date :

1-7 daysPurity : 99%

Shape : Multiple

Material : Boron Nitride Ceramic

Boron Nitride Nozzle Features

1. High Temperature Resistance: Boron nitride ceramic nozzles are designed to withstand temperatures up to 3000°F. This makes them perfect for use in applications such as plasma cutting and welding.

2. Low Thermal Conductivity: Boron nitride ceramic nozzles have a low thermal conductivity, making them ideal for directing and focusing a stream of hot gas or plasma in one direction.

3. Chemical Inertness: Boron nitride ceramic nozzles are highly resistant to most chemicals, including acids, alkalis, and organic solvents. This makes them ideal for applications such as etching or cleaning.

4. Non-Wetting: Boron nitride ceramic nozzles are non-wetting, meaning they won’t be affected by liquid or gas. This makes them perfect for directing and controlling streams of pressurized gas or liquid.

5. High Mechanical Strength: Boron nitride ceramic nozzles are incredibly strong, allowing them to withstand high pressures and temperatures without breaking or cracking. This makes them perfect for use in high-pressure applications.

BN Nozzle Application

1.Boron nitride ceramic nozzles are used in a wide variety of applications, such as in semiconductor manufacturing, automotive and aerospace industries, and chemical and petrochemical processing.

2.They are also used in the food and beverage industry, in medical and dental equipment, and in research and development applications.

3.In semiconductor manufacturing, boron nitride ceramic nozzles are used in the deposition of thin films, such as for the deposition of copper for semiconductor interconnects.

4.They are also used for chemical vapor deposition (CVD) of dielectric films, such as for the fabrication of integrated circuits.

5.In the automotive and aerospace industries, boron nitride ceramic nozzles are used for the application of coatings and for the atomization of lubricants and other fluids.

6.In the chemical and petrochemical processing industry, boron nitride ceramic nozzles are used in the production of fine particles, such as for the production of powders, or for the atomization of liquids.

7.In the food and beverage industry, boron nitride ceramic nozzles are used for the spraying of flavorings and preservatives.

8.In medical and dental equipment, boron nitride ceramic nozzles are used for the spraying of coatings, for aerosol delivery of medications, and for the atomization of dental materials.

9.In research and development applications, boron nitride ceramic nozzles are used for the atomization of liquids and for the production of fine particles.

BN Ceramic Propeties

Grade

BN99

CABN

Compositions

BN>98.5%

BN>97.5%

Binder

B2O3

CaB2O3

Density(g/cm3)

1.95~2.0

2.0~2.1

25℃ Volume Resistivity(Ω·cm)

>1014

>1013

Max. Service Temp. (℃)

Oxygen

900

900

Inert Gas

2400

2400

High Vacuum

2200

2200

Three-point

30

70

Flexural Strength(Mpa)

Compressive Strength(Mpa)

100

100

Coefficient of Thermal Expansion

1.5

2

25~1000℃(10-6/K)

Thermal Conductivity(W/mK)

15

20

OEM Service

1. Ability to design and manufacture custom boron nitride ceramic nozzles to meet exact specifications.

2. Experience in the production of boron nitride ceramic nozzles with tight tolerances.

3. Ability to produce boron nitride ceramic nozzles with a variety of dimensions and shapes.

4. Use of advanced production technologies to ensure high-quality and reliable products.

5. Use of top quality raw materials and components to ensure consistent product performance.

6. Completion of rigorous testing processes to ensure the highest quality standards are met.

7. Ability to produce boron nitride ceramic nozzles in large quantities.

8. Flexibility to provide a variety of customization options for boron nitride ceramic nozzles.

9. Competitive pricing and timely delivery of products.

10. A commitment to customer service and satisfaction.

We provide Multiple shapes here for reference, if you are interesting about it, please contact with us.

Boron Nitride Ceramics Test Standard

Standard Test Method for :

Packing & Shipping

We keep stock for almost all models of crucible in the warehouses .The shortest order lead time and delivery time can be within 5-7 days after receiving order confirmation, which ensures on time and in full delivery for any urgent order.

Why Choose US

As a professional industrial ceramic supplier, we have a series of advantages that guarantee our market share in the international trade market.

1.Reliable quality control, complete specifications, support customization of non-standard products.

2.Professional and committed service team.

3.Multiple protection of packaging, secure and reliable.

4.Highly efficient delivery channel, safe and rest-assured.

FAQ

1.Q: What are boron nitride nozzles?

A: Boron nitride nozzles are a specialized type of nozzle made from a boron nitride composite material. These nozzles are designed to handle higher temperatures and higher pressures than other nozzle materials, making them ideal for use in high-temperature industrial applications.

2.Q: What are the advantages of using boron nitride nozzles?

A: Boron nitride nozzles are extremely resistant to wear and tear, making them a great choice for industrial applications which require long-term performance. They can also handle higher temperatures and pressures than other nozzles, making them ideal for use in high-temperature applications.

Next :

Boron Nitride Tube Boron Nitride Ceramic Parts

Boron Nitride Ceramic Parts

Boron nitride ceramics are a hot new material in the advanced ceramics market, and are used in a wide range of industrial applications. BN is ideal for applications requiring high thermal conductivity, chemical inertness, and electrical insulation.

Boron Nitride Ceramic density Plates

Boron Nitride Ceramic density Plates

Boron Nitride Plate / Sheet is made of powdered hexagonal boron nitride through high-temperature vacuum hot-pressing sintering. CS Ceramic provides customers with high-quality Boron Nitride Plates / Sheets.

Boron Nitride Ceramic Rods

Boron Nitride Ceramic Rods

Boron nitride is an excellent electrical insulator that has a higher oxidation temperature. It offers high thermal conductivity and good thermal shock resistance and can be easily machined to close tolerances in virtually any shape.

Cylinder Boron nitride Crucibles with Lid

Cylinder Boron nitride Crucibles with Lid

Boron Nitride is a synthetic technical ceramic material. It has outstanding thermal characteristics.and excellent thermal shock resistance. The unique property of BN crucible is that it is non-wetting with molten metal.

Boron Nitride Tube

Boron Nitride Tube

Boron Nitride Tube, BN Tube, is made of powdered hexagonal boron nitride through high-temperature vacuum hot-pressing sintering. Heeger Materials is a worldwide supplier of high-quality Boron Nitride Tubes and other boron nitride products.

60μl Alumina pans 5.0 mm Equivalent to Rigaku 8592A3 (DSC Crucibles)

60μl Alumina pans 5.0 mm Equivalent to Rigaku 8592A3 (DSC Crucibles)

Rigaku 8592A3 60μl Alumina crucibles sample pans for Rigaku STDA DSC and TGA measurements. Manufacturer for Rigaku SII, Bruker crucibles and sample pans.

Square Zirconia Smelting Crucible

Square Zirconia Smelting Crucible

ZrO2 crucible's extreme heat resistance and excellent thermal shock resistance make it ideal for performing high-temperature processes such as melting and annealing metals, as well as for storing, mixing, and heating hazardous materials.

Aluminum crucible lids for 45/95 μl Al crucible equivalent to Netzsch J1560184 for STA 2500 Regulus

Aluminum crucible lids for 45/95 μl Al crucible equivalent to Netzsch J1560184 for STA 2500 Regulus

Manufacturer for Netzsch crucibles and sample cups. Netzsch Instruments good alternative DSC sample pans.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522