Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read Moreitem no. :

CS-DHP-B1001Color :

WhitePort :

Any ports of Chinalead date :

5-7 daysPurity : 99.99%

Shape : Square / Round

Material : Boron Nitride

Original Country : China

BN Ceramic Sheet Features

1. High thermal conductivity and excellent heat resistance .

2. Low thermal expansion and excellent dimensional stability .

3. High chemical resistance to acids and alkalis.

4. High electrical resistance and excellent electrical insulation properties .

5. Excellent lubricity and wear resistance .

6. High thermal shock resistance and good thermal shock stability .

7. Excellent machinability and can be easily machined to desired shapes .

8. Non-porous and resistant to moisture absorption.

Boron Nitride Products Applications

1. Used as a heat sink in semiconductor devices, such as transistors, diodes and integrated circuits.

2. Used as a thermal barrier or insulator in high temperature applications.

3. Used in the production of semiconductor chips.

4. Used as a dielectric material in capacitors and other electrical components.

5. Used in abrasive machining and grinding applications.

6. Used for planarizing substrates in the manufacture of microelectronic components.

7. Used as a wear-resistant coating in industrial applications.

8. Used as a protective coating in high temperature applications.

9. Used as a lubricant in high temperature applications.

10. Used as an insulating material in the aerospace and automotive industries.

Boron Nitride Property

| Grade | BN99 | CABN | ALBN | ZSBN | ZABN | SBN |

| Compositions | BN>98.5% | BN>97.5% | AlN+BN | ZrO2+BN | ZrO2+AlN+BN | SiC+BN |

| Binder | B2O3 | CaB2O3 | AlBO3 | B2O3 | AlBO3 | AlBO3 |

| Density(g/cm3) | 1.95~2.0 | 2.0~2.1 | 2.6 | 2.9~3.0 | 3.2~3.3 | 2.4~2.6 |

| 25℃ Volume Resistivity(Ω·cm) | >1014 | >1013 | >1014 | >1012 | >1012 | >1012 |

| Max. Service Temp. (℃) | ||||||

| Oxygen | 900 | 900 | 900 | 1000 | 900 | 900 |

| Inert Gas | 2400 | 2400 | 2100 | 1800 | 1800 | 1700 |

| High Vacuum | 2200 | 2200 | 1900 | 1800 | 1800 | 1700 |

| Three-point | 30 | 70 | 130 | 120 | 130 | 91 |

| Flexural Strength(Mpa) | ||||||

| Compressive Strength(Mpa) | 100 | 100 | 250 | 280 | 300 | 300 |

| Coefficient of Thermal Expansion | 1.5 | 2 | 4.5 | 5 | 5 | 4 |

| 25~1000℃(10-6/K) | ||||||

| Thermal Conductivity(W/mK) | 15 | 20 | 50 | 20 | 40 | 40 |

Boron Nitride Squate Plate Specification

| Shape | Item | Length / mm | Width / mm | Thickness / mm | Purity |

| BN Square Plate | CS-DHP-B001 | 5 | 5 | 0.5-5 | 99.99% |

| BN Square Plate | CS-DHP-B002 | 10 | 10 | 0.5-10 | 99.99% |

| BN Square Plate | CS-DHP-B003 | 20 | 20 | 0.5-20 | 99.99% |

| BN Square Plate | CS-DHP-B004 | 100 | 100 | 1 | 99.99% |

| BN Square Plate | CS-DHP-B005 | 100 | 100 | 1-10 | 99.99% |

| BN Square Plate | CS-DHP-B006 | 200 | 200 | 1-10 | 99.99% |

| BN Square Plate | CS-DHP-B007 | 15 | 8 | 0.5-10 | 99.99% |

| BN Square Plate | CS-DHP-B008 | 19 | 10 | 0.5-10 | 99.99% |

| BN Square Plate | CS-DHP-B009 | 23 | 15 | 0.5-10 | 99.99% |

| BN Square Plate | CS-DHP-B010 | 28 | 22 | 0.5-10 | 99.99% |

| BN Square Plate | CS-DHP-B011 | 30 | 20 | 0.5-10 | 99.99% |

| BN Square Plate | CS-DHP-B012 | 45.5 | 32.5 | 0.5-20 | 99.99% |

| BN Square Plate | CS-DHP-B013 | 40 | 35 | 0.5-20 | 99.99% |

| BN Square Plate | CS-DHP-B014 | 76 | 52 | 0.5-20 | 99.99% |

| BN Square Plate | CS-DHP-B015 | 88 | 75 | 0.5-20 | 99.99% |

| BN Square Plate | CS-DHP-B016 | 93 | 70 | 0.5-5 | 99.99% |

| BN Square Plate | CS-DHP-B017 | 130 | 100 | 0.5-5 | 99.99% |

| BN Square Plate | CS-DHP-B018 | 160 | 100 | 0.5-5 | 99.99% |

| BN Square Plate | CS-DHP-B019 | 175 | 80 | 0.5-5 | 99.99% |

| BN Square Plate | CS-DHP-B020 | 190 | 75 | 0.5-5 | 99.99% |

BN Round Specification

| Shape | Item | Length / mm | Thickness / mm | Purity |

| BN Round Plate | CS-DHP-B1001 | 9 | 1mm/2mm/3.175mm/4mm/5mm/6mm/6.35mm | 99.99% |

| BN Round Plate | CS-DHP-B1002 | 13 | 1mm/2mm/3.175mm/4mm/5mm/6mm/6.35mm | 99.99% |

| BN Round Plate | CS-DHP-B1003 | 16 | 1mm/2mm/3.175mm/4mm/5mm/6mm/6.35mm | 99.99% |

| BN Round Plate | CS-DHP-B1004 | 18 | 1mm/2mm/3.175mm/4mm/5mm/6mm/6.35mm | 99.99% |

| BN Round Plate | CS-DHP-B1005 | 20 | 1mm/2mm/3.175mm/4mm/5mm/6mm/6.35mm | 99.99% |

| BN Round Plate | CS-DHP-B1006 | 21 | 1mm/2mm/3.175mm/4mm/5mm/6mm/6.35mm | 99.99% |

| BN Round Plate | CS-DHP-B1007 | 23 | 1mm/2mm/3.175mm/4mm/5mm/6mm/6.35mm | 99.99% |

| BN Round Plate | CS-DHP-B1008 | 25 | 1mm/2mm/3.175mm/4mm/5mm/6mm/6.35mm | 99.99% |

| BN Round Plate | CS-DHP-B1009 | 25.4 | 1mm/2mm/3.175mm/4mm/5mm/6mm/6.35mm | 99.99% |

| BN Round Plate | CS-DHP-B1010 | 50.8 | 1mm/2mm/3.175mm/4mm/5mm/6mm/6.35mm | 99.99% |

| BN Round Plate | CS-DHP-B1011 | 60 | 1mm/2mm/3.175mm/4mm/5mm/6mm/6.35mm | 99.99% |

| BN Round Plate | CS-DHP-B1012 | 76.2 | 1mm/2mm/3.175mm/4mm/5mm/6mm/6.35mm | 99.99% |

| BN Round Plate | CS-DHP-B1013 | 75 | 1mm/2mm/3.175mm/4mm/5mm/6mm/6.35mm | 99.99% |

| BN Round Plate | CS-DHP-B1014 | 100 | 1mm/2mm/3.175mm/4mm/5mm/6mm/6.35mm | 99.99% |

| BN Round Plate | CS-DHP-B1015 | 101.6 | 1mm/2mm/3.175mm/4mm/5mm/6mm/6.35mm | 99.99% |

BN Sheets Test Standard

1. Hardness: Measured by a standard Vickers or Rockwell scale.

2. Thermal Conductivity: Measured using a Thermal Conductivity Meter.

3. Fracture Toughness: Measured using a three point bend test.

4. Porosity: Measured using a standard porosity test.

5. Density: Measured using a standard density tester.

6. Compressive Strength: Measured using a standard compression tester.

7. Thermal Shock Resistance: Measured using a standard thermal shock test.

8. Chemical Resistance: Measured by a standard chemical resistance test.

OEM Services 1. Customized shapes and sizes based on customer requirements.

2. Precision machining to achieve tight tolerances.

3. Ability to withstand extreme temperatures, pressures, and wear.

4. Resistance to corrosion, abrasion, and chemical attack.

5. Quality assurance and testing to ensure product meets all specifications.

6. Fast turnaround time for prototyping and production.

7. Competitive pricing and competitive lead times.

8. Ability to provide custom packaging and labeling.

Packing & Shippment

CS’s Boron Nitride Products are carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

Use/Maintenance Methods 1. The use temperature in the air should not exceed 1000 degrees. The surface of boron nitride in contact with oxygen will be oxidized and spalling if it exceeds 1000 degrees.

Why Choose US

As a professional industrial ceramic supplier, we have a series of advantages that guarantee our market share in the international trade market.

1. Sufficient inventory (delivery within 1-3 days)

2, multiple materials (yttrium stability, calcium stability)

3, complete size (diameter 3.5-120mm thickness 0.25-6mm)

4, service life (according to the material used by customers, cleaning and preservation decision)

5, quality assurance (each board has passed 100% strict testing before leaving the factory)

6, the quality of the commitment (quality problems we bear the freight return package)

7. Preferential price (direct selling manufacturers, manufacturing enterprises, global direct selling)

8, quality service (according to customer requirements of customized production)

9. Sincere attitude (professional and technical personnel analyze and solve various problems for customers)

1.Q: What are Boron Nitride Ceramic Plates?

A: Boron nitride ceramic plates are manufactured using a unique process that combines extreme heat and pressure to form a ceramic material that is incredibly strong, lightweight, and thermally stable. Boron nitride ceramic plates are used in a variety of applications, from medical and dental implants to industrial components and aerospace components. The plates are typically machined to the required shapes and sizes, and can be purchased in standard sizes or custom sizes.

2.Q: What are the advantages of using Boron Nitride Ceramic Plates?

A: Boron nitride ceramic plates are ideal for applications that require a strong, lightweight material that is thermally stable. Additionally, boron nitride ceramic plates are non-toxic, non-conductive, and highly resistant to oxidation and corrosion. This makes them useful for a variety of applications in medical, industrial, and aerospace industries. Additionally, these plates can be machined to custom shapes and sizes, allowing for greater versatility and customization in their applications.

Q: What industries use Boron Nitride Ceramic Plates?

A: Boron nitride ceramic plates are used in a variety of industries, including medical and dental implants, aerospace components, and industrial components. Additionally, these plates can be used as heat shields and thermal barriers in high-temperature applications.

Previous:

Boron Nitride Ceramic RodsNext :

Boron Nitride Ceramic Parts Boron Nitride Ceramic Parts

Boron Nitride Ceramic Parts

Boron nitride ceramics are a hot new material in the advanced ceramics market, and are used in a wide range of industrial applications. BN is ideal for applications requiring high thermal conductivity, chemical inertness, and electrical insulation.

Boron Nitride Ceramic Rods

Boron Nitride Ceramic Rods

Boron nitride is an excellent electrical insulator that has a higher oxidation temperature. It offers high thermal conductivity and good thermal shock resistance and can be easily machined to close tolerances in virtually any shape.

Cylinder Boron nitride Crucibles with Lid

Cylinder Boron nitride Crucibles with Lid

Boron Nitride is a synthetic technical ceramic material. It has outstanding thermal characteristics.and excellent thermal shock resistance. The unique property of BN crucible is that it is non-wetting with molten metal.

Boron Nitride Ceramic Nozzle

Boron Nitride Ceramic Nozzle

Boron nitride (BN) nozzles made of hot pressed boron nitride ceramics have outstanding thermal shock resistance, crack or break will not happen when boron nitride nozzles undergo sudden heating or cooling.

Boron Nitride Tube

Boron Nitride Tube

Boron Nitride Tube, BN Tube, is made of powdered hexagonal boron nitride through high-temperature vacuum hot-pressing sintering. Heeger Materials is a worldwide supplier of high-quality Boron Nitride Tubes and other boron nitride products.

TGA 2950 Ceramic T/C Tube Baffle equivalent to TA 952111.001

TGA 2950 Ceramic T/C Tube Baffle equivalent to TA 952111.001

For TA Instruments are designed to provide reliable and accurate sample analysis. The pans are designed to fit perfectly into the TA Instruments

Quartz Probes Expansion Probe Thermomechanical Analyzer Probes For TA TMA Q400/TMA 450

Quartz Probes Expansion Probe Thermomechanical Analyzer Probes For TA TMA Q400/TMA 450

Quartz Probes For TA TMA Q400/TMA 450.They are designed to be used in expansion,penetration,flexural and tension modes of deformation and are used to determine coefficient of thermal expansion,shrinkage,softening points,sintering temperatures, elongation and much more.

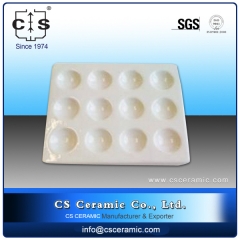

12 Hollows Porcelain Spotting Color Plates Labware

12 Hollows Porcelain Spotting Color Plates Labware

1.Used for PH tests or qualitative analysis of solutions for precipitate formatio. 2. Resist temperature is to be 1050 degrees centigrade.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522