Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

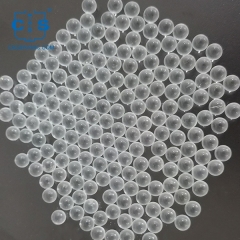

Read MoreTungsten carbide milling balls have excellent hardness, wear resistance, chemical inertness, and durability,they are widely used in various grinding applications. Available in various sizes.

item no. :

CS-NW1-001Material : Tungsten Carbide

Purity Available : 90%

Shape : ball

1. Exceptional Hardness: Tungsten carbide is one of the hardest materials known, making the milling balls highly wear-resistant.

2. High Temperature Resistance: Tungsten carbide can endure extreme temperatures without significant deformation or deterioration.

3. Chemical Inertness: Tungsten carbide is chemically inert and resistant to many corrosive substances, acids, and alkalis.

4. Reduced Contamination: Tungsten carbide is non-reactive with most materials, minimizing the risk of contamination during milling.

5. High Wear Resistance: The wear resistance of tungsten carbide milling balls ensures minimal material loss due to abrasion during milling operations, leading to improved efficiency and cost savings.

6. Longevity: They have a longer operational lifespan compared to other milling media, reducing downtime for replacement and maintenance.

7. Reduced Energy Consumption: The hardness and wear resistance of tungsten carbide milling balls can lead to reduced energy consumption in milling equipment, as they require less frequent replacement and maintenance.

8. Environmental Benefits: Longer-lasting tungsten carbide milling balls can result in less waste generation and reduced environmental impact compared to less durable alternatives.

1. Tungsten carbide grinding balls are mainly made of composite materials composed of tungsten carbide particles and are an advanced professional grinding medium.

2. They have excellent hardness and wear resistance, and are widely used in various grinding applications.

3. They are key components in grinding equipment and processes, helping to reduce particle size, mix materials, and produce fine powders.

4. The grinding ball size can be customized according to different milling applications and equipment.

Tungsten Carbide Milling Balls

Item No.

Diameter(mm)

Item No.

Diameter(mm)

CS-NW1-001

0.1

CS-NWB6-007

6

CS-NW2-002

0.2

CS-NWB6.5-008

6.5

CS-NW3-003

0.3

CS-NWB7-009

7

CS-NW4-004

0.4

CS-NWB7.5-010

7.5

CS-NW5-005

0.4-0.6

CS-NWB8-011

8

CS-NW6-006

0.6-0.8

CS-NWB8.5-012

8.5

CS-NW7-007

0.7-0.9

CS-NWB9-013

9

CS-NW8-008

0.8-1.0

CS-NWB9.5-014

9.5

CS-NWB3-001

3

CS-NWB10-015

10

CS-NWB3.5-002

3.5

CS-NWB10.5-016

10.5

CS-NWB4-003

4

CS-NWB11-017

11

CS-NWB4.5-004

4.5

CS-NWB11.5-018

11.5

CS-NWB5-005

5

CS-NWB12-019

12

CS-NWB5.5-006

5.5

CS-NWB12.5-020

12.5

1. Ball Milling: Tungsten carbide milling balls are commonly used as grinding media in ball mills for materials processing, including the pulverization of minerals, ores, ceramics, and various chemicals.

2. Planetary Ball Milling: In planetary ball mills, tungsten carbide milling balls are used for high-energy milling and mixing of materials, particularly in research and development laboratories.

3. High-Energy Milling: In industries such as electronics and nanotechnology, they are used to produce fine powders, nanoparticles, and advanced materials.

4. Metallurgy: In metallurgical applications, they can be used for crushing and grinding metal ores and alloys.

5. Paints and Coatings: In the production of coatings, coatings, and inks, they help to disperse and grind pigments and fillers.

6. Environmental Remediation: Tungsten carbide milling balls can be used in environmental applications for the milling and grinding of contaminated soil and sediments to remediate hazardous waste sites.

7. Automotive: Automotive manufacturers employ tungsten carbide milling balls in precision machining applications for engine components and other critical parts.

| Specific Gravity | Vickers Hardness | Crushing Strength | Fracture Toughness | Elastic Modulus |

| >14.5kg/dm3 | >1500kg/mm2 | >250gf(2mm) | >15MPa.m½ | >710Gpa½ |

Q1. Can I reuse tungsten carbide milling balls?

Yes, tungsten carbide milling balls can be reused multiple times due to their wear resistance and durability. Regular cleaning and proper maintenance help extend their lifespan.

Q2. Are there different sizes available for tungsten carbide milling balls?

Yes, tungsten carbide milling balls come in various sizes and diameters to suit different milling applications. Selecting the appropriate size is important for achieving desired particle sizes and milling results.

Q3. How do I store tungsten carbide milling balls when not in use?

Store tungsten carbide milling balls in a clean, dry container to prevent contamination and maintain their quality. Avoid exposure to moisture and corrosive substances.

Q4. Can I recycle tungsten carbide milling balls?

Yes, tungsten carbide is a recyclable material. Many companies offer recycling programs for used carbide tools and products, including milling balls. Contact recycling centers or manufacturers for details.

1. Wear Protective Gear: Before handling the grinding balls, wear appropriate personal protective equipment such as gloves and safety goggles to prevent skin contact and eye irritation.

2. Remove Residue: If there are visible residues on the grinding balls, gently remove them using a soft brush or cloth. Avoid using abrasive materials that could scratch the surface.

3. Rinse with Solvent: For thorough cleaning, immerse the grinding balls in a suitable solvent or cleaning solution.Allow the grinding balls to soak for a few minutes to loosen any adhered particles.

4. Agitate Gently: Gently agitate the solution to help dislodge any particles or contaminants from the surface of the grinding balls.

5. Rinse with Distilled Water: After cleaning in the solvent, rinse the grinding balls with distilled water to remove any residual solvent or cleaning solution.

6. Dry Thoroughly: Place the cleaned grinding balls on a clean surface or in a container lined with a lint-free cloth to air dry.

1. Visual Inspection: Look for any cracks, chips, or visible wear on the surface of the balls. Check for any signs of deformation, dents, or irregularities.

2. Uniformity: Examine the milling balls for uniformity in size, shape, and overall appearance. Irregularities might affect milling performance.

3. Measure Dimensions: Measure the size of beads using calipers. Check for consistency in size, as deviations can affect their performance in applications like grinding and milling.

4.Hardness Testing: If you have the equipment and expertise, you can perform hardness tests on a representative sample of milling balls. Compare the results to the expected hardness range for tungsten carbide.

1. We supply personalized and customized services to contact your personal needs.

2. We are experienced professionals with a good record of success.

3. We provide superior client service and promptly respond to all inquiries.

4. We provide militant prices and strive to ensure that your funds receive the best value.

5. We use the latest technologies and tools to ensure that your project is completed to the highest standards.

Agate Balls Grinding / Milling Balls

Agate Balls Grinding / Milling Balls

Agate grinding balls are made of high-quality natural agate,aiming to improve the accuracy and efficiency of the grinding and grinding process. Its smooth surface minimizes equipment wear while ensuring excellent grinding performance.

Silicon Nitride Grinding Balls Si4N3 Milling Ball

Silicon Nitride Grinding Balls Si4N3 Milling Ball

Silicon nitride grinding ball ceramic milling ball has exceptional hardness, wear resistance, chemical inertness, and thermal stability. These properties make it an ideal choice for precision grinding applications in various industries.

Zirconia Milling Balls ZrO2 Ceramic Grinding Ball

Zirconia Milling Balls ZrO2 Ceramic Grinding Ball

Zirconia grinding balls ceramic milling balls have high wear resistance and are suitable for various materials, reducing replacement frequency,and efficient grinding.Customizable with various purities and sizes.

Glass Beads Grinding Ball Milling Media

Glass Beads Grinding Ball Milling Media

Glass beads grinding balls milling media have chemically inert, gentle and efficient grinding, cross application versatility, easy cleaning and reuse.Available in various sizes.

Yttria Stabilized Zirconia Beads Ceramic Grinding Media Balls

Yttria Stabilized Zirconia Beads Ceramic Grinding Media Balls

Yttria stabilized zirconia beads grinding media balls have high hardness, wear resistance, chemical inertness, and high temperature resistance. Available in various sizes and shapes.

Chrome Steel Grinding Balls

Chrome Steel Grinding Balls

Chrome steel grinding balls offer high hardness,wear resistance,impact toughness,and corrosion resistance.They have a long operational life,and are versatile across various industrial applications.Available in various sizes.

Ceria Stabilized Zirconia Beads Ceramic Milling Balls Grinding Medium

Ceria Stabilized Zirconia Beads Ceramic Milling Balls Grinding Medium

Ceria stabilized zirconia beads have high thermal stability, enhanced mechanical strength, chemical inertness, ion conductivity. Products can be customized according to the required size and different ceria content.

Zirconia Ceramic Blasting Beads

Zirconia Ceramic Blasting Beads

Zirconia ceramic blasting beads are known for their exceptional hardness, durability, uniform size and shape and resistance to wear. They can efficiently remove hard coatings and pollutants.Available in various sizes.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522