Silicon carbide (SiC) is a lightweight ceramic material with high strength properties comparable to diamond. It has high thermal conductivity, low thermal expansion, thermal shock resistance, oxidation resistance, and corrosion resistance. Silicon carbide is an excellent ceramic raw material for applications requiring good erosion and abrasive resistance.

-

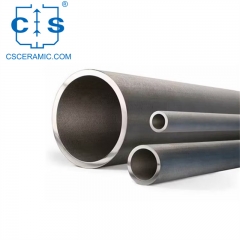

SiC Heat Exchanger Tube & Tube Sheet Core for Shell & Tube UnitsSilicon carbide heat exchange tube & tube sheet, core of shell-and-tube exchangers, transfers heat between fluids of different temps.

SiC Heat Exchanger Tube & Tube Sheet Core for Shell & Tube UnitsSilicon carbide heat exchange tube & tube sheet, core of shell-and-tube exchangers, transfers heat between fluids of different temps. -

igh-Efficiency Silicon Carbide Vacuum Chuck for Solar CellsThe silicon carbide vacuum chuck, featuring small holes connected to a vacuum pump, generates a pressure difference to securely absorb thin, light items like wafers, chips, and solar cells.

igh-Efficiency Silicon Carbide Vacuum Chuck for Solar CellsThe silicon carbide vacuum chuck, featuring small holes connected to a vacuum pump, generates a pressure difference to securely absorb thin, light items like wafers, chips, and solar cells. -

No Leak CQ Stainless Steel Magnetic Drive Pump SiC Lined Full SealThe SiC lined CQ magnetic drive pump, a new product applying the principle of permanent magnetic coupling to centrifugal pumps, features a reasonable design, advanced technology, full seal, no leakage, and corrosion resistance.

No Leak CQ Stainless Steel Magnetic Drive Pump SiC Lined Full SealThe SiC lined CQ magnetic drive pump, a new product applying the principle of permanent magnetic coupling to centrifugal pumps, features a reasonable design, advanced technology, full seal, no leakage, and corrosion resistance. -

Heavy-Duty SiC Ceramic Pump Shaft for Harsh ConditionsThe SiC shaft, crafted from high-purity powder, excels in mechanical properties & chemical stability, ideal for harsh conditions like high temp, corrosion, & heavy loads.

Heavy-Duty SiC Ceramic Pump Shaft for Harsh ConditionsThe SiC shaft, crafted from high-purity powder, excels in mechanical properties & chemical stability, ideal for harsh conditions like high temp, corrosion, & heavy loads. -

Silicon Carbide Ceramic Shaft Sleeve for Engines Motors ReducersThe Silicon Carbide Shaft Sleeve is installed between bearing and shaft in rotating devices like engines, motors, reducers, and pumps, reducing friction, wear, and extending lifespan.

Silicon Carbide Ceramic Shaft Sleeve for Engines Motors ReducersThe Silicon Carbide Shaft Sleeve is installed between bearing and shaft in rotating devices like engines, motors, reducers, and pumps, reducing friction, wear, and extending lifespan. -

High-Hardness SiC Grinding Balls Precision Bearing BallsHigh-hardness SiC balls, wear, heat & corrosion-resistant, ideal for ultra-fine grinding & high-precision ball bearings.

High-Hardness SiC Grinding Balls Precision Bearing BallsHigh-hardness SiC balls, wear, heat & corrosion-resistant, ideal for ultra-fine grinding & high-precision ball bearings. -

SiC Wafer Carrier Bracket Diffusion Furnace Tool for Semiconductors & Solar CellsSiC Boat Bracket is crucial for carrying wafers into diffusion furnaces for coating in semiconductor & PV production.

SiC Wafer Carrier Bracket Diffusion Furnace Tool for Semiconductors & Solar CellsSiC Boat Bracket is crucial for carrying wafers into diffusion furnaces for coating in semiconductor & PV production. -

Wear-Resistant SiC Ceramic Bolt & Screw FastenersHigh-Strength Silicon Carbide Bolt, wear & corrosion-resistant, fastens parts securely, ideal for high-temp & harsh environments.

Wear-Resistant SiC Ceramic Bolt & Screw FastenersHigh-Strength Silicon Carbide Bolt, wear & corrosion-resistant, fastens parts securely, ideal for high-temp & harsh environments. -

Silicon Carbide Ceramic Cone Liner for Metallurgy & Chemical PipelinesHigh-hardness Silicon Carbide Cone Liner, wear & corrosion-resistant, ideal for harsh powder & liquid pipelines in metallurgy, chemicals, & power industries.

Silicon Carbide Ceramic Cone Liner for Metallurgy & Chemical PipelinesHigh-hardness Silicon Carbide Cone Liner, wear & corrosion-resistant, ideal for harsh powder & liquid pipelines in metallurgy, chemicals, & power industries.

info@csceramic.com

info@csceramic.com

+86 18273288522

+86 18273288522