Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read Moreitem no. :

CS-THG-CZ1001Material : SiC

Please provide drawing and parameter requirements for customization.

| Silicon Carbide Tray SiC PVD Tray | |||

| Item NO. |

Diameter (mm) |

Thickness (mm) |

SiC's Purity (%) |

| CS-THG-CZ1001 | 230 | 3 | 99 |

| CS-THG-CZ1002 | 300 | 1.4 | 99 |

| CS-THG-CZ1003 | 300 | 3 | 99 |

| CS-THG-CZ1004 | 330 | 1.4 | 99 |

| CS-THG-CZ1005 | 330 | 3 | 99 |

| Silicon Carbide Tray SiC ICP Tray | |||

| Item NO. |

Diameter (mm) |

Thickness (mm) |

SiC's Purity (%) |

| CS-THG-CZ2001 | 300 | 3 | 99 |

| CS-THG-CZ2002 | 300 | 4.4 | 99 |

| CS-THG-CZ2003 | 330 | 4.4 | 99 |

| CS-THG-CZ2004 | 330 | 3 | 99 |

| CS-THG-CZ2005 | 380 | 4.4 | 99 |

| CS-THG-CZ2006 | 380 | 3 | 99 |

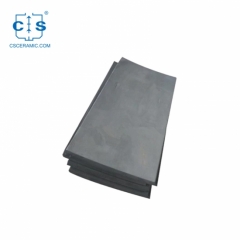

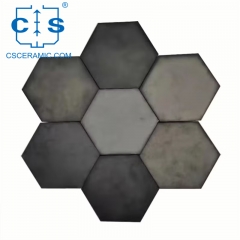

Multiple Shape Silicon Carbide Ceramic Plates

Multiple Shape Silicon Carbide Ceramic Plates

Silicon carbide ceramics are known for their lightweight and high strength, allowing them to provide superior protection from bullets, shrapnel, and other ballistic threats.

Silicon Carbide Kiln Fish Plate

Silicon Carbide Kiln Fish Plate

Silicon carbide kiln shelves, also kiln furniture sic plate setter, are widely used for the loading structure systems of tunnel kilns, shuttle kilns and many other industrial kilns.

NIJ IV Level SiC Ceramic Bulletproof Plate for Armor Lining & Protective Shielding

NIJ IV Level SiC Ceramic Bulletproof Plate for Armor Lining & Protective Shielding

The SiC ceramic bulletproof plate boasts high hardness (HV2600+), NIJ IV-level protection, ideal for body armor lining & vehicle, aircraft, & ship armor.

High-Power SiC Ceramic Substrate Conductive & Semi-Insulating Types

High-Power SiC Ceramic Substrate Conductive & Semi-Insulating Types

SiC substrate, basic material for semiconductor chips, in conductive & semi-insulating types, supports high-temp, high-voltage, large-power apps, available in 2-8 inches (50-200mm) diameters.

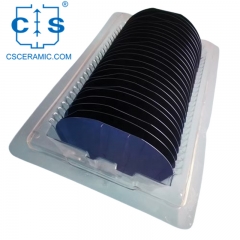

SiC Wafer for MOSFETs, Schottky Diodes, & Photodiodes

SiC Wafer for MOSFETs, Schottky Diodes, & Photodiodes

Silicon carbide wafer, a new-gen semiconductor material, is used to manufacture MOSFETs, Schottky diodes, photodiodes, & other electronic devices.

High-Speed SOI Wafers Low-Power Silicon-on-Insulator for ICs & MEMS

High-Speed SOI Wafers Low-Power Silicon-on-Insulator for ICs & MEMS

SOI wafers, silicon-on-insulator where a thin layer of silicon sits on an insulating substrate, enable high-speed, low-power operation by reducing capacitance, leakage current, and enhancing switching speeds, widely adopted in microelectronics and emerging in photonics & MEMS.

Porcelain Ware Ceramic Combustion Tube unglazed

Porcelain Ware Ceramic Combustion Tube unglazed

1.Unglazed,hard porcelain 2.For Carbon and Sulphur determinations. 3.Good thermal shock property and mechanical strength.

Tzero Low Mass Pans 901670.901 for TA Instruments Q20/Q200( Sample Cups)

Tzero Low Mass Pans 901670.901 for TA Instruments Q20/Q200( Sample Cups)

TA Tzero 901670.901 Aluminum Sample Pans is compatible for TA Instruments TZero Q20/Q200. Manufacturer for TA crucibles and DSC sample pans. TA Instruments Thermal analysis crucibles good alternative sample cups. TA 901670.901.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522