Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

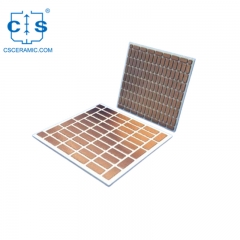

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

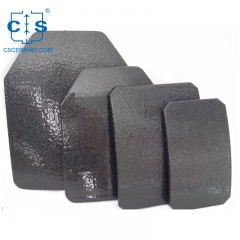

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read Moreitem no. :

CS-DHG-JB001Material : Si3N4

Exceptional High-Temperature Resistance: The Silicon Nitride Substrate boasts an impressive maximum use temperature of up to 1300℃, making it ideal for applications requiring extreme thermal stability.

Superior Thermal Conductivity & Low Thermal Expansion: With a thermal conductivity of up to 95W/(℃m) and a minimal thermal expansion coefficient of just 310-6/℃, this substrate exhibits exceptional thermal shock resistance, ensuring stability and durability in temperature-fluctuating environments.

Robust Mechanical Strength & Impact Resistance: Characterized by high mechanical strength and remarkable toughness, the Silicon Nitride Substrate withstands severe mechanical impacts without compromising performance, ensuring reliability in demanding applications.

Excellent Electrical Insulation Properties: Boasting great electric insulation, a high breakdown voltage, and substantial current carrying capacity, this substrate is an optimal choice for electrical and electronic components requiring superior dielectric strength.

Outstanding Chemical Resistance: Capable of resisting erosion from a wide range of acids, alkalis, and other chemical substances, the Silicon Nitride Substrate demonstrates exceptional corrosion resistance, making it suitable for harsh and aggressive chemical environments.

Electronic Industry Applications

Photoelectric Industry

Electrical Industry

Please provide drawing and parameter requirements for customization.

| Si3N4 Substrate Square and Rectangular | |||

| Item No. |

Length (mm) |

Width (mm) |

Thickness (mm) |

| CS-DHG-JB001 | 10 | 10 | 0.32 |

| CS-DHG-JB002 | 20 | 20 | 0.32 |

| CS-DHG-JB003 | 30 | 30 | 4.0 |

| CS-DHG-JB004 | 40 | 40 | 0.5 |

| CS-DHG-JB005 | 50 | 50 | 0.32 |

| CS-DHG-JB006 | 50 | 50 | 0.635 |

| CS-DHG-JB007 | 50 | 50 | 1.0 |

| CS-DHG-JB008 | 50 | 50 | 2.0 |

| CS-DHG-JB009 | 50 | 50 | 4.0 |

| CS-DHG-JB010 | 50 | 50 | 9.0 |

| CS-DHG-JB011 | 100 | 100 | 0.3 |

| CS-DHG-JB012 | 100 | 100 | 0.5 |

| CS-DHG-JB013 | 100 | 100 | 0.6 |

| CS-DHG-JB014 | 100 | 100 | 1.0 |

| CS-DHG-JB015 | 100 | 100 | 4.0 |

| CS-DHG-JB016 | 100 | 100 | 9.0 |

| CS-DHG-JB017 | 114 | 114 | 0.3 |

| CS-DHG-JB018 | 114 | 114 | 0.5 |

| CS-DHG-JB019 | 114 | 114 | 0.6 |

| CS-DHG-JB020 | 114 | 114 | 1.0 |

| CS-DHG-JB021 | 190 | 138 | 0.3 |

| CS-DHG-JB022 | 190 | 138 | 0.5 |

| CS-DHG-JB023 | 190 | 138 | 0.6 |

| CS-DHG-JB024 | 190 | 138 | 1.0 |

| Si3N4 Substrate Round | ||

| Item No. |

Diameter (mm) |

Thickness (mm) |

| CS-DHG-JB025 | 5 | 0.25 |

| CS-DHG-JB026 | 5 | 0.32 |

| CS-DHG-JB027 | 5 | 0.625 |

| CS-DHG-JB028 | 5 | 1 |

| CS-DHG-JB029 | 10 | 0.25 |

| CS-DHG-JB030 | 10 | 0.32 |

| CS-DHG-JB031 | 10 | 0.625 |

| CS-DHG-JB032 | 10 | 1 |

| CS-DHG-JB033 | 20 | 0.25 |

| CS-DHG-JB034 | 20 | 0.32 |

| CS-DHG-JB035 | 20 | 0.625 |

| CS-DHG-JB036 | 20 | 1 |

| CS-DHG-JB037 | 40 | 0.25 |

| CS-DHG-JB038 | 40 | 0.32 |

| CS-DHG-JB039 | 40 | 0.625 |

| CS-DHG-JB040 | 40 | 1 |

| CS-DHG-JB041 | 50 | 0.25 |

| CS-DHG-JB042 | 50 | 0.32 |

| CS-DHG-JB043 | 50 | 0.625 |

| CS-DHG-JB044 | 50 | 1 |

| CS-DHG-JB045 | 100 | 0.32 |

| CS-DHG-JB046 | 100 | 1 |

| CS-DHG-JB047 | 100 | 2 |

| CS-DHG-JB048 | 150 | 0.32 |

| CS-DHG-JB049 | 150 | 1 |

| CS-DHG-JB050 | 150 | 2 |

| CS-DHG-JB051 | 150 | 20 |

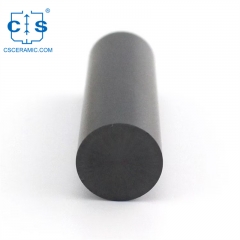

High-Purity Si3N4 Ceramic Rod, Silicon Nitride Bar for Mechanical & High-Temp Applications

High-Purity Si3N4 Ceramic Rod, Silicon Nitride Bar for Mechanical & High-Temp Applications

The high-purity Silicon Nitride Ceramic Rod boasts hardness, wear, high-temp,making it ideal for mechanical parts, kiln rollers, & support rods.

Silicon Nitride Ceramic Plate Si3N4

Silicon Nitride Ceramic Plate Si3N4

The silicon nitride exhaust hood offers high temp & corrosion resistance, good electrical insulation. It's ideal for reduction furnaces to vent gases while blocking debris.

AMB Metalized Si3N4 Ceramic Substrate for High-Power Device Packaging

AMB Metalized Si3N4 Ceramic Substrate for High-Power Device Packaging

The AMB silicon nitride substrate, offers electrical function, ideal for packaging high-voltage, high-power devices used in EVs, rail transit, smart grids, and aerospace.

High-Temp Silicon Nitride Ceramic Shaft Sleeve for Engines

High-Temp Silicon Nitride Ceramic Shaft Sleeve for Engines

High-temperature sintered silicon nitride ceramic shaft sleeve, used in rotating mechanical devices like engines, reduces friction, extending shaft lifespan.

High-Purity Si3N4 Ceramic Plunger for Plunger Pumps & Hydraulic Systems

High-Purity Si3N4 Ceramic Plunger for Plunger Pumps & Hydraulic Systems

High-purity silicon nitride ceramic plunger offers high strength, wear durability, self-lubrication, ideal for plunger pumps & hydraulic system components.

HHigh-Temp Silicon Nitride Insulation Ring Si3N4 for Polysilicon Furnace

HHigh-Temp Silicon Nitride Insulation Ring Si3N4 for Polysilicon Furnace

The Silicon Nitride Ceramic Insulation Ring is vital in polysilicon reduction furnaces, effectively safeguarding electrodes and polycrystalline silicon rods under high temperatures, ensuring stable and safe silicon rod production.

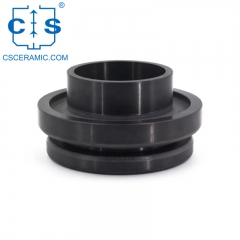

Heat-Resistant Silicon Nitride Seal Ring Si3N4 Sealant Ring for Gas/Liquid Leak Prevention

Heat-Resistant Silicon Nitride Seal Ring Si3N4 Sealant Ring for Gas/Liquid Leak Prevention

The Silicon Nitride sealing ring, crafted from ceramic is widely used in mechanical equipment & pipeline joints to prevent leaks.

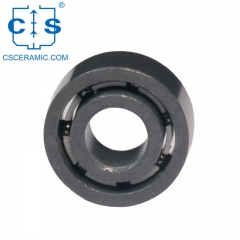

High-Performance Si3N4 Ceramic Ball Bearing

High-Performance Si3N4 Ceramic Ball Bearing

The Silicon Nitride Bearing is a high-performance option, featuring lightweight design, ideal for harsh environments & high-speed applications.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522