Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read MoreAlumina ceramic water valve plate is an essential component of many fluid control systems, providing reliable and long-lasting performance in even the most demanding environments.Available in various sizes and shapes.

item no. :

CS-V-0199.5% 99.7% 99% 90% 92% 95%

Material : Alumina ceramic

Shape : OEM

Size : 11.5mm-40mm

1. Alumina ceramic water valve plates is highly resistant to abrasion, wear, and corrosion, making it a highly durable.

2. It is able to withstand high temperatures, making it ideal for use in environments where hot water or steam is present.1600℃ in long use,1800℃ in short use (Al2O3≥99%).

3. Alumina ceramic is highly resistant to corrosion, which makes water valve plates made of this material ideal in corrosive environments.

4. It has a low friction coefficient, which makes alumina water valve plate highly efficient and smooth in operation.

5. It requires minimal maintenance and do not require replacement for prolonged periods, reducing operating costs.

6. It offers high accuracy in controlling the flow of water, ensuring that the correct amount of water is distributed.

7. It is a cost-effective material, which makes water valve plates affordable for various applications.

1. Alumina ceramic water valve plate is high-quality, precision-engineered components used in a variety of applications involving the control of fluid flow.

2. Constructed from alumina ceramic, these valve plates are extremely durable and can withstand high temperatures, high pressures, and corrosive environments without degradation.

3. The surface of these valve plates is polished to a mirror-like finish to ensure minimal friction and optimal sealing.

4. Alumina ceramic water valve plate is designed to operate at high speeds, making it ideal for applications requiring fast response times.

5. Alumina ceramic water valve plate is an essential component of many fluid control systems, providing reliable and long-lasting performance in even the most demanding environments.

Alumina ceramic Water Valve Plates

Item number

Diameter(mm)

CS-V-01

11.5

CS-V-02

12

CS-V-03

13.5

CS-V-04

14.5

CS-V-05

15

CS-V-06

15.5

CS-V-07

15.7

CS-V-08

15.8

CS-V-09

16

CS-V-10

16.1

CS-V-11

16.2

CS-V-12

19

CS-V-13

20.7

CS-V-14

21

CS-V-15

25

CS-V-16

35

CS-V-17

40

OEM

By drawing

| Item | Test Condition | 95% AL2O3 | 99% AL2O3 | 99.5% AL2O3 | ||

| Physical properties | Density | g/cm3 | >3.6 | 3.89 | 3.96 | |

| Moisture absorption | % | 0 | 0 | 0 | ||

| Mechanical properties | ROHS Hardness | ≥85 | ≥89 | ≥89 | ||

| Flexural strength | psiX103 | 20℃ | 358 | 550 | 550 | |

| Compressive strength | psiX103 | 20℃ | 2068(300) | 2600(377) | 2600(377) | |

| Fracture toughness | Mpa.m3/2 | K(l c) | 4.3 | 5.6 | 6 | |

| Thermal properties | Maximum use temperature | ℃ | 1450 | 1600 | 1650 | |

| Thermal expansion coefficient | 1X10-6/℃ | (25-1000℃) | 7.6 | 7.9 | 8.2 | |

| Thermal shock resistance | ℃ | Tc | 250 | 200 | 200 | |

| Thermal conductivity | w/mok | 20℃ | 16 | 30 | 30.4 | |

| Electrical properties | Volume resistivity | Ohm/cm2 | 100℃ | >1013 | >1014 | >1014 |

| Dielectric breakdown strength | KV/mm | 8.7(220) | 8.7(220) | 8.7(220) | ||

| Dielectric constant | (E) | 1MHz25℃ | 9 | 9.7 | 9.7 | |

| Dielectric constant (100MHz) | (E) | 9.5 | ||||

1. Industrial application: Alumina ceramic water valve plates can be used in various industries such as chemical engineering, oil and gas, water treatment, etc.

2. Semiconductor manufacturing: In semiconductor manufacturing, it can be used to produce etching gases and chemicals.

3. Medical equipment: It can be used for dialysis machines, oxygen making machines, ventilator and other medical equipment.

4. Aerospace space industry: in the aerospace space industry, it can be used for rocket engines, satellite propulsion systems and aircraft engines. This ceramic water valve plate can withstand high temperatures and harsh environments, making it an ideal choice for space and aviation applications.

5. Power generation:It can be used in the power plant to control the flow of fluid and gas in the turbine, boilers and other equipment.The ceramic water valve board can withstand high pressure and high temperature, which is an ideal choice for power generation applications.

Q1. What information should we supply to get a quote?

Please offer the specification of alumina ceramic water valve plate, such as shape, dimension, quantity, application etc.

Q2. Can alumina ceramic water valve plates be customized according to specific requirements?

Yes, alumina ceramic water valve plates can be customized according to specific requirements, such as size, shape, and thickness, to suit different applications and needs.

Q3. How long do alumina ceramic water valve plates last?

Alumina ceramic water valve plates have a long life span and can last for several years, depending on the operating conditions and environment.

Q4. What are the maintenance requirements for alumina ceramic water valve plates?

Alumina ceramic water valve plates require minimal maintenance and can last for a long time without the need for replacement. However, regular cleaning and inspection are recommended to ensure proper functioning and to prevent damage or wear.

1. First, wipe the alumina ceramic water valve plate with a damp cloth to remove dust and dirt.

2. Use a soft bristle brush and a mild detergent solution to scrub the alumina ceramic water valve plate.

3. Wash the alumina ceramic water valve plate with clean water, and then dry it with a soft cloth.

4. Ensure that the alumina ceramic water valve plate is dry when used next time.

1. Visual inspection of the alumina ceramic water valve plate for any signs of damage or irregularities.

2. Measurement the dimensions of the alumina ceramic water valve plate to check for accuracy.

3. Checking for any pinhole defects in the alumina ceramic water valve plate.

4. Verification of the material and chemical composition of the alumina ceramic water valve plate.

1. We supply personalized and customized services to contact your personal needs.

2. We are experienced professionals with a good record of success.

3. We provide superior client service and promptly respond to all inquiries.

4. We provide militant prices and strive to ensure that your funds receive the best value.

5. We use the latest technologies and tools to ensure that your project is completed to the highest standards.

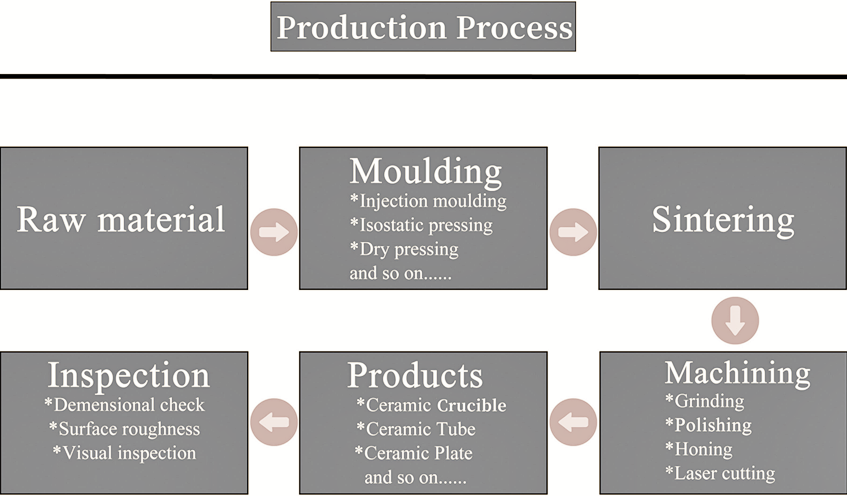

High Mechanical Strength Alumina Steatite Ceramic Parts

High Mechanical Strength Alumina Steatite Ceramic Parts

Alumina steatite ceramic parts are an ideal choice for components that require minimal maintenance and have a long life,they have excellent electrical insulation and thermal shock resistance.Available in various sizes.

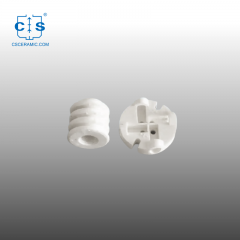

Alumina Ceramic Thermocouple Insulator Tubes

Alumina Ceramic Thermocouple Insulator Tubes

Alumina ceramic thermocouple insulated tubes provide excellent insulation performance and durable durability, used to isolate thermocouples from high temperatures and corrosive environments.Available in various sizes.

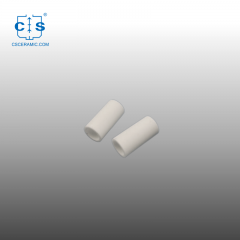

Alumina Ceramic Laser Reflector

Alumina Ceramic Laser Reflector

CS CERAMIC is committed to delivering high-quality alumina ceramic laser reflector tailored to your exact specifications.

Alumina Bushing Ceramic Insulator

Alumina Bushing Ceramic Insulator

Alumina Bushing Ceramic Insulator for cable terminations. Multiple fluted and capped bushings, re-entrant bushings, tubular bushings, barrel and cylindrical bushings, etc. can be customized.

Alumina Ceramic Ball Bearing Ceramic Bushings

Alumina Ceramic Ball Bearing Ceramic Bushings

Alumina ceramic ball bearing is a type of bearing that uses ceramic balls in order to reduce friction and improve bearing performance.These bushings are designed to reduce maintenance costs and extend the life of equipment.

Industrial Alumina Ceramic Piston Parts

Industrial Alumina Ceramic Piston Parts

Alumina ceramic piston adopts the ultra-hard wear resistance of modern engineering ceramic materials, can be assembled by ceramic metallization bonding,welding and socket technology.Available in various sizes.

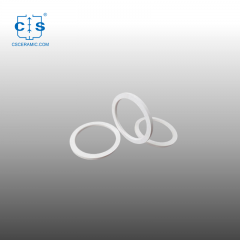

High Alumina Ceramic Washer Ceramic Seal

High Alumina Ceramic Washer Ceramic Seal

Alumina ceramic washer ceramic seal is used as seals for a variety of applications.These rings are designed to provide a tight,reliable seal that won't leak or break down over time.Available in various sizes.

95% to 99% Alumina Ceramic Washer Ceramic Seal Ring

95% to 99% Alumina Ceramic Washer Ceramic Seal Ring

Alumina washer ceramic seal ring is used as seals for a variety of applications. These rings are designed to provide a tight, reliable seal that won't leak or break down over time.All sizes can be customized.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522