Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read More

item no. :

CS-QTZ-P001Material : Quartz glass

Purity Available : 99.98%

Shape : Square Circle

Advantages of transparent quartz plate:

1. Quartz glass plate can withstand a high temperature without cracking or melting. Long term use at 1100 ℃, short term use at 1450 ℃.

2. It has excellent transparency and is very suitable for applications requiring high optical clarity such as spectroscopy, optics, and laser technology.

3. The low coefficient of thermal expansion means that it can withstand temperature fluctuations without cracking or warping.

4. It is very durable, and its mechanical strength makes it resistant to impacts and scratches, making it durable.

5. Easy to clean with high-pressure water, steam, or ultrasound, it is a low maintenance material.

6. It is resistant to ultraviolet radiation and is very suitable for applications that require exposure to ultraviolet radiation, such as curing systems for printing machines, lithography machines, etc.

Descriptions of transparent quartz plate:

1. These plates are made from 99.98% pure quartz glass material, ensuring superior optical clarity and high-temperature tolerance.

2. They have an excellent ability to block UV radiation, making them essential in applications such as UV curing, light filtering, and sterilization.

3. Quartz glass plates are highly versatile and can be utilized in a variety of applications. From laboratory experiments to semiconductor manufacturing, these plates offer superior performance and precision.

4. Available in a range of sizes, thicknesses, and shapes, making them highly versatile.

Size details of transparent quartz plate:

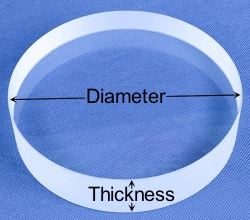

Size details of quartz glass disc

Item NO.

Purity

Item NO.

Purity

CS-QTZ-P001

10

1

99.98%

CS-QTZ-P015

70

5

99.98%

CS-QTZ-P002

15

1

99.98%

CS-QTZ-P016

80

2

99.98%

CS-QTZ-P003

15

2

99.98%

CS-QTZ-P017

80

3

99.98%

CS-QTZ-P004

20

1

99.98%

CS-QTZ-P018

80

5

99.98%

CS-QTZ-P005

20

2

99.98%

CS-QTZ-P019

90

5

99.98%

CS-QTZ-P006

25

1

99.98%

CS-QTZ-P020

100

1

99.98%

CS-QTZ-P007

25

2

99.98%

CS-QTZ-P021

100

2

99.98%

CS-QTZ-P008

30

1

99.98%

CS-QTZ-P022

100

3

99.98%

CS-QTZ-P009

30

2

99.98%

CS-QTZ-P023

100

5

99.98%

CS-QTZ-P010

60

1

99.98%

CS-QTZ-P024

150

2

99.98%

CS-QTZ-P011

60

2

99.98%

CS-QTZ-P025

150

3

99.98%

CS-QTZ-P012

60

5

99.98%

CS-QTZ-P026

150

5

99.98%

CS-QTZ-P013

70

2

99.98%

CS-QTZ-P027

10-90

1-20

99.98%

CS-QTZ-P014

70

3

99.98%

CS-QTZ-P028

91-450

1-20

99.98%

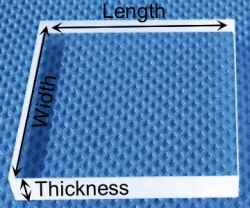

Size details of quartz glass plate

Item NO.

Purity

Item NO.

Purity

CS-QTZ-P1001

15

5

1

99.98%

CS-QTZ-P1013

70

70

5

99.98%

CS-QTZ-P1002

10

10

1

99.98%

CS-QTZ-P1014

80

80

5

99.98%

CS-QTZ-P1003

15

15

1

99.98%

CS-QTZ-P1015

100

100

1

99.98%

CS-QTZ-P1004

15

15

2

99.98%

CS-QTZ-P1016

100

100

1.5

99.98%

CS-QTZ-P1005

20

20

1

99.98%

CS-QTZ-P1017

100

100

2

99.98%

CS-QTZ-P1006

20

20

2

99.98%

CS-QTZ-P1018

100

100

3

99.98%

CS-QTZ-P1007

25

25

1

99.98%

CS-QTZ-P1019

100

100

5

99.98%

CS-QTZ-P1008

25

25

2

99.98%

CS-QTZ-P1020

150

150

2

99.98%

CS-QTZ-P1009

30

30

1

99.98%

CS-QTZ-P1021

150

150

3

99.98%

CS-QTZ-P1010

30

30

2

99.98%

CS-QTZ-P1022

150

150

5

99.98%

CS-QTZ-P1011

60

60

1

99.98%

CS-QTZ-P1023

10-450

10-450

1-20

99.98%

CS-QTZ-P1012

60

60

2

99.98%

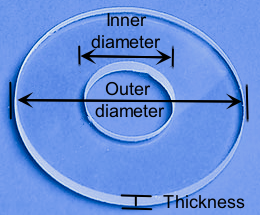

Size details of quartz glass circle ring

Item NO.

Purity

CS-QTZ-H001

9

5

1-10

99.98%

CS-QTZ-H002

16

6

1-10

99.98%

CS-QTZ-H003

30

20

1-10

99.98%

CS-QTZ-H004

42

30

5-20

99.98%

CS-QTZ-H005

56

24

5-20

99.98%

CS-QTZ-H006

65

30

5-20

99.98%

CS-QTZ-H007

73

55

5-20

99.98%

CS-QTZ-H008

84

42

5-20

99.98%

CS-QTZ-H009

95

65

5-20

99.98%

CS-QTZ-H010

102

80

5-20

99.98%

CS-QTZ-H011

103

83

8

99.98%

CS-QTZ-H012

120

55

5-20

99.98%

CS-QTZ-H013

135

95

5-20

99.98%

CS-QTZ-H014

165

100

5-20

99.98%

Parameters of quartz glass plate:

| Chemical composition: | SiO2 99.9% |

| Density: | 2.2(g/cm3) |

| Degree of hardness moh' scale: | 6.6 |

| Melting point: | 1732℃ |

| Working temperature: | 1100℃ |

| Max temperature can reach in a short time: | 1450℃ |

| Acid tolerance: | 30 times than Ceramics , 150 times than Stainless steel |

| Visible light transmittance: | above 93% |

| UV spectral region transmittance: | 80% |

| Resistance value: | 10000 times than ordinary glass |

| Annealing point: | 1215℃ |

| Softening point: | 1730℃ |

Applications of transparent quartz plate:

1. Optical applications: Quartz glass plates are widely used in optical instruments like microscopes, telescopes, and cameras.

2. Chemical applications: These plates can be used as covers for reaction vessels, gas samples, or liquid samples.

3. Semiconductor applications: They are also used in semiconductor manufacturing processes, such as chemical vapor deposition (CVD) and wafer cleaning. Quartz wafers have a high thermal resistance, high chemical resistance, and excellent surface flatness, making them ideal for use in lithography and other process steps.

4. Medical applications: They are used in medical equipment like spectroscopy devices, refractometers, and other specialized instruments.

5. Solar applications: They are used in the manufacturing of solar cells and panels.

6. Aerospace applications: They used in the aerospace industry as protective covers for sensors, probes, and communication systems. They are also used as windows for aircraft and spacecraft cabins due to their high-temperature resistance, high strength, and low thermal expansion.

7. Research and development: Quartz glass plates are widely used in research and development to facilitate experimentation, as they are easily cleanable and have minimal reactivity with most materials. They are used as substrates for assembling nanodevices, as windows for high-pressure experiments, and as a substrate for conducting materials research.

FAQ

Q1. What information should we supply to get a quote?

Please offer the specification of quartz glass plate, such as shape, dimension, quantity, application etc.

Q2. How do I maintain quartz glass plates?

Regularly clean quartz glass plates. In order to maintain the optical quality of glass, it is important to wear clean gloves for processing and store it in a clean and dust-free environment.

Q3. How long is the lifespan of a quartz glass plate?

The lifespan of a quartz glass plate depends on its usage and exposure to harsh chemicals, high temperatures, and other environmental factors. If maintained properly, a quartz glass plate can last for many years.

Q4. What is the lead time for the quartz glass plate?

The lead time is dependent on the size and quantity required. Please contact us for more information.

How to clean transparent quartz plate:

1. Use a mild soap or detergent mixed with warm water. Avoid using harsh chemicals or abrasive cleaners that can damage the quartz glass.

2. Immerse the quartz glass plates in the cleaning solution for at least 10-15 minutes.

3. After soaking, use a soft-bristled brush or cloth to gently scrub the plates. Do not apply too much pressure as you may scratch or damage the surface of the quartz glass.

4. Use clean water to rinse the plates thoroughly, removing all traces of the cleaning solution.

5. Use a soft, dry cloth or towel to wipe the plates dry.

Quality testing standards:

1. Visual inspection of the quartz glass plate for any signs of damage or irregularities.

2. Measurement of the length, width, and thickness of the quartz glass plate to check for accuracy.

3. Hold the quartz glass plate against a light source and inspect it for transparency. Transparent quartz glass should allow light to pass through it easily with little to no distortion.

4. Pour a small amount of water on the surface of the quartz glass plate and observe the behavior of the water. If the water beads up and does not properly wet the surface of the quartz glass plate, it may indicate a coating of impurities on the surface.

5. Verification of the material and chemical composition of the quartz glass plate.

Packing way:

Why Choose us?

1. We supply personalized and customized services to contact your personal needs.

2. We are experienced professionals with a good record of success.

3. We provide superior client service and promptly respond to all inquiries.

4. We provide militant prices and strive to ensure that your funds receive the best value.

5. We use the latest technologies and tools to ensure that your project is completed to the highest standards.

OEM Platinum Sample Pans D5mm*H5mm for TA Instruments

OEM Platinum Sample Pans D5mm*H5mm for TA Instruments

OEM Platinum/Pt Crucibles Platinum/Pt Sample Pans for TA Instruments . Manufacturer for TA crucibles and DSC sample pans. TA Instruments good alternative sample cups.

Evaporating Dish Uses in Laboratory for Quantitative Analysis

Evaporating Dish Uses in Laboratory for Quantitative Analysis

1. Capacity is from 15ml to 5000ml. 2. Porcelain basins,Round bottom with spout. Labware could satisfied different testing requirement.

Customized Aluminum Nitride Sheets

Customized Aluminum Nitride Sheets

Aluminum nitride substrates offers high electrical insulation for a variety of electrical uses. A variety of specifications available. Satisfying various machining request.

Aluminum lids for 900 μL alumina pans equivalent to ME 51140469

Aluminum lids for 900 μL alumina pans equivalent to ME 51140469

ME 51140469 Aluminum lids covers for Mettler DSC and TGA measurements. Manufacturer for Mettler Toledo crucibles and sample pans.

Copper Lid suit for ME-51140407 For Mettler Toledo/SHIMADZU(Sample pans)

Copper Lid suit for ME-51140407 For Mettler Toledo/SHIMADZU(Sample pans)

D6 copper crucible cover ME-51140407 Copper crucibles sample pans for Mettler DSC and TGA measurements. Manufacturer for Mettler Toledo crucibles and sample pans.

3ml Linseis STA Ceramic Crucibles for Linseis (Sample Pans)

3ml Linseis STA Ceramic Crucibles for Linseis (Sample Pans)

3ml Linseis STA special shape alumina pan for Linseis STA DSC and TGA measurements. Manufacturer for Linseis crucibles and sample pans.

Burst Disk Gold-plated for Mettler Toledo Disposable High Pressure Crucible

Burst Disk Gold-plated for Mettler Toledo Disposable High Pressure Crucible

Disk used with high pressure disposable crucible. Manufacturer of thermal analysis crucible consumables for Mettler Toledo DSC & TGA equipment.

270 μL HP Ni Alloy crucible with pin equivalent to ME-650072

270 μL HP Ni Alloy crucible with pin equivalent to ME-650072

Manufacturer of thermal analysis crucible consumables for Mettler Toledo DSC & TGA equipment.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522