Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read Moreitem no. :

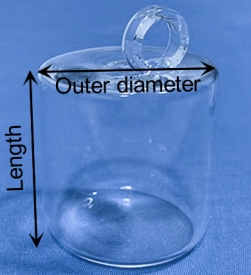

CS-QTZ-F001Material : Quartz glass

Purity Available : 99.98%

Advantages of quartz blocks for tube furnace:

1. High Durability: Quartz is a highly durable material, and quartz blocks can withstand high temperatures and pressure, making them ideal for use in tube furnaces.

2. Chemical Resistance: With high chemical corrosion resistance, it is an excellent choice for applications with chemical reactions.

3. High Thermal Insulation: They are excellent insulation materials, so they can protect the tubular furnace from excessive heat loss and keep the surrounding environment cool.

4. Optimal Transparency: Transparent to light of various wavelengths. This feature is beneficial when conducting experiments that require observing the sample during the heating process.

5. Precise Heating: With high thermal conductivity, it can reduce the temperature gradient of the entire sample. This characteristic ensures that the sample is heated uniformly, which is critical for reproducible results.

6. Ease of Maintenance: Easy to clean with minimal maintenance, making it a suitable choice for daily use in laboratories and industry.

7. Availability: They are readily available in the market, making them easy to replace if damaged.

8. Versatility: Quartz blocks can be shaped in various geometries and sizes, making them customizable to fit a specific tube furnace design.

Descriptions of quartz blocks for tube furnace:

1. Quartz blocks for tube furnace are made from high-purity quartz, our blocks for tube furnace provide excellent thermal insulation, reducing energy consumption and costs.

2. They offer high dimensional stability, resistance to thermal shock, and low thermal expansion, making them ideal for tube furnace applications.

3. The blocks are easy to install and maintain for all your furnace needs.

4. They are designed to provide superior heat resistance and thermal shock protection for your tube furnace.

Size details of quartz blocks for tube furnace:

Quartz blocks for tube furnace

Item NO.

Length (mm)

Purity

Remarks

CS-QTZ-F001

20

65

99.98%

Used for furnace tube with an outer diameter 30mm

CS-QTZ-F002

30

65

99.98%

Used for furnace tube with an outer diameter 40mm

CS-QTZ-F003

40

65

99.98%

Used for furnace tube with an outer diameter 50mm

CS-QTZ-F004

50

65

99.98%

Used for furnace tube with an outer diameter 60mm

CS-QTZ-F005

60

65

99.98%

Used for furnace tube with an outer diameter 70mm

CS-QTZ-F006

70

65

99.98%

Used for furnace tube with an outer diameter 80mm

CS-QTZ-F007

90

65

99.98%

Used for furnace tube with an outer diameter 100mm

CS-QTZ-F008

110

65

99.98%

Used for furnace tube with an outer diameter 120mm

OEM/ODM is acceptable. Your goods will be produced exactly according to your drawings or inquiry.

Parameters of quartz blocks:

| Chemical composition: | SiO2 99.98% |

| Density: | 2.2(g/cm3) |

| Degree of hardness moh' scale: | 6.6 |

| Melting point: | 1732℃ |

| Working temperature: | 1100℃ |

| Max temperature can reach in a short time: | 1450℃ |

| Acid tolerance: | 30 times than Ceramics , 150 times than Stainless steel |

| Visible light transmittance: | above 93% |

| UV spectral region transmittance: | 80% |

| Resistance value: | 10000 times than ordinary glass |

| Annealing point: | 1215℃ |

| Softening point: | 1730℃ |

Applications of quartz blocks for tube furnace:

1. Annealing and Tempering: Quartz blocks can be used in tube furnaces for annealing and tempering of various materials. The precise temperature control of the tube furnace combined with the high thermal stability of quartz blocks make it an ideal application for annealing and tempering.

2. Heat Treatment: In a tubular furnace, used to heat treat materials in a controlled environment.

3. Chemical Vapor Deposition: Quartz blocks can be used in tube furnaces for chemical vapor deposition (CVD) of various materials. The quartz blocks provide a clean and stable environment for CVD, ensuring the quality and reproducibility of the final product.

4. Growth of Single Crystals: Used to grow single crystals of various materials in a tube furnace.The quartz blocks provide a stable temperature enironment for crystal growth, which is critical for producing high-quality crystals.

5. Powder Sintering: Used for powder sintering of various ceramics and metals. The high thermal stability of quartz blocks ensures the uniformity of temperature throughout the sintering process, resulting in high-quality sintered products.

6. Drying and Calcination: Used for drying and calcination of various materials. The high thermal stability of quartz blocks ensures that the materials are heated uniformly to achieve the desired result.

FAQ

Q1. What information should we supply to get a quote?

Please offer the specification of quartz blocks, such as shape, dimension, quantity, application etc.

Q2. How are quartz blocks for tube furnace installed?

Quartz blocks for tube furnace are typically installed in the tube of the furnace and secured in place with clamps or other fastening devices.

Q3. What types of tube furnaces are compatible with quartz blocks?

Quartz blocks are compatible with most tube furnace designs, including muffle furnaces, horizontal tube furnaces, and vertical tube furnaces.

Q4. How long do quartz blocks for tube furnace last?

Quartz blocks for tube furnace typically have a long lifespan and can last for many years with proper maintenance and care.

Q5. What kind of maintenance is required for quartz blocks for tube furnace?

Quartz blocks for tube furnace do not require regular maintenance. However, it is important to check them periodically for signs of wear and tear, such as cracks or chips. If any damage is found, the block should be replaced immediately.

How to clean quartz blocks:

1. Remove any remaining material from the quartz block using a soft brush or soft cloth.

2. Fill a container with warm water and add a small amount of detergent.

3. Submerge the block in the detergent water and let it soak for several minutes.

4. Use a soft brush or cloth to gently scrub the block, paying special attention to any stubborn stains or deposits.

5. Rinse the block thoroughly with clean water to remove all detergent residue.

6. Dry the block with a soft cloth or let it air dry.

Quality testing standards:

1. Visual inspection of the quartz block for any signs of damage or irregularities.

2. Measurement of the length, width, and thickness of the block to check for accuracy.

3. Hold the block against a light source and inspect it for transparency. Transparent quartz glass should allow light to pass through it easily with little to no distortion.

4. Verification of the material and chemical composition of the block.

Packing way:

Why Choose us?

1. We supply personalized and customized services to contact your personal needs.

2. We are experienced professionals with a good record of success.

3. We provide superior client service and promptly respond to all inquiries.

4. We provide militant prices and strive to ensure that your funds receive the best value.

5. We use the latest technologies and tools to ensure that your project is completed to the highest standards.

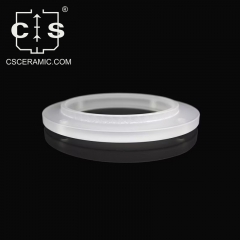

Thermal Shock Stable Quartz Flange for Pipe & Equipment Connections

Thermal Shock Stable Quartz Flange for Pipe & Equipment Connections

The quartz flange, corrosion & high-temp resistant with good thermal shock tolerance, small expansion coef., & excellent chemical stability, connects pipes & equipment in harsh environments.

Optical Transmittance Quartz Etching Ring for Semiconductor Etching

Optical Transmittance Quartz Etching Ring for Semiconductor Etching

The high-purity quartz etching ring, resistant to high temp & corrosion, guides gases for precise semiconductor etching, ensuring quality & efficiency.

High-Purity Quartz Wafer Boat for Semiconductor & PV Diffusion Furnaces

High-Purity Quartz Wafer Boat for Semiconductor & PV Diffusion Furnaces

The high-purity quartz wafer boat, a vital component in semiconductor & PV production, loads wafers for diffusion & oxidation in furnaces.

Quartz Wafer Boat Carrier for Semiconductor & PV Cell Production

Quartz Wafer Boat Carrier for Semiconductor & PV Cell Production

The quartz wafer boat bracket, a vital component in semiconductor & photovoltaic production, carries wafers or solar cells for diffusion & oxidation in furnaces.

Thermal Insulation Quartz Furnace Door for PV Cell Production

Thermal Insulation Quartz Furnace Door for PV Cell Production

The quartz furnace door is widely used in PV diffusion, annealing, and oxidation furnaces for stable temperature and atmosphere control.

Quartz Source Jar Insulates Well for Solar Cell Production

Quartz Source Jar Insulates Well for Solar Cell Production

The quartz furnace door, resistant to high temps, thermal shock, acids, & alkalines, ensures stable temp & atmosphere in PV diffusion, annealing, & oxidation furnaces.

High-Purity Quartz Waste Liquid Filter Bottle for Solar Cell Diffusion Process Purification

High-Purity Quartz Waste Liquid Filter Bottle for Solar Cell Diffusion Process Purification

The high-purity quartz waste liquid bottle, resistant to high temp & thermal shock, offers excellent light transmission, corrosion resistance, and is ideal for filtering & precipitating solar cell diffusion waste liquid, separating solids for purification.

UV to NIR Transmission Quartz Sight Glass for Boilers, Smelting & Chemical Industries

UV to NIR Transmission Quartz Sight Glass for Boilers, Smelting & Chemical Industries

The high-purity quartz glass mirror boasts temperature & corrosion resistance, low thermal expansion, good thermal shock resistance, and superior optical performance, making it ideal for boilers, smelting, chemical, and other industrial monitoring applications.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522