Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read Moreitem no. :

CS-THG-BU001Color :

BlackPort :

Any ports of Chinalead date :

5-7 daysMaterial : Silicon Carbide

Purity : 99%

Shape : U-shape

Original Country : China

1. The Silicon Carbide Heating Rod has excellent thermal shock resistance and high thermal efficiency.

2. Silicon Carbide Heating Rods are used in many high temperature applications such as furnace heating, sintering, heat treatment, glass and ceramic production and other temperature control processes.

3. Silicon Carbide Heating Rods are constructed from high purity Silicon Carbide materials, providing superior performance, low cost and long working life.

4. Silicon Carbide Heating Rods can withstand high temperatures up to 1472°F (800°C) and can be used in a wide range of applications.

5. Silicon Carbide Heating Rods are available in a variety of shapes, sizes and lengths to meet your needs.

Heating Rod Applications

1.They are commonly used in kilns, furnaces, boilers, ovens, and other high-temperature applications.

2.They are also used in semiconductor fabrication, glass production, and metal processing.

3.Silicon Carbide Heating Rods can also be used in the production of chemicals, ceramics, and food processing equipment.

4.Silicon Carbide Heating Rods are highly heat conductive, making them an efficient and cost-effective choice for many heating applications.

Sic Heating Element Rod Propeties

PROPERTIES

UNIT

VALUE

Color

/

Gray

Hardness

Mohs

9.5

Density

g/cm3

3

Thermal conductivity at

Btu/fthF @300℃

50

Compressive Strength

PSI

500,000

Flexural Strength

PSI

70,000

Max service temperature

℃

1600

Linear Coe. Of thermal Expansion (25C-600C)

10-6/℃

4

Heating Rod Specifications

U-type Heating Elements

Heating zone OD / mm

Heating zone Length / mm

Cold zone Length / mm

center distance / mm

Bridge OD / mm

Overall length / mm

Range of resistance / Ω

Purity

CS-THG-BU001

14

200

250

40

14

54

2.4-4.6

99%

CS-THG-BU002

14

250

300

50

14

64

3.0-6.0

99%

CS-THG-BU003

14

300

350

60

14

74

3.6-7.0

99%

CS-THG-BU004

16

200

250

40

16

56

1.4-2.8

99%

CS-THG-BU005

16

250

300

50

16

66

1.8-3.6

99%

CS-THG-BU006

16

300

350

60

16

76

2.0-5.0

99%

CS-THG-BU007

18

300

350

60

18

78

2.0-5.0

99%

CS-THG-BU008

18

400

400

70

18

88

2.8-5.8

99%

CS-THG-BU009

18

500

450

75

18

93

3.6-7.2

99%

CS-THG-BU010

20

250

300

50

20

70

1.8-3.6

99%

CS-THG-BU011

20

300

350

60

20

80

2.0-5.0

99%

CS-THG-BU012

20

400

400

70

20

90

2.8-5.8

99%

CS-THG-BU013

25

400

400

70

25

95

1.6-3.4

99%

CS-THG-BU014

25

500

450

75

25

100

2.2-4.4

99%

CS-THG-BU015

25

600

500

80

25

105

2.6-5.2

99%

CS-THG-BU016

30

600

400

70

30

100

1.4-2.8

99%

CS-THG-BU017

30

700

450

75

30

105

1.6-3.2

99%

CS-THG-BU018

30

800

500

80

30

110

1.8-3.6

99%

Three Phase Type

Heat zone OD / mm

Heating zone length / mm

Cold zone Length / mm

center distance / mm

Bridge OD / mm

Overall length / mm

Purity

CS-THG-BF001

14

200

250

40

14

54

99%

CS-THG-BF002

14

250

300

50

14

64

99%

CS-THG-BF003

14

300

350

60

14

74

99%

CS-THG-BF004

16

200

250

40

16

56

99%

CS-THG-BF005

16

250

300

50

16

66

99%

CS-THG-BF006

16

300

350

60

16

76

99%

CS-THG-BF007

18

300

350

60

18

78

99%

CS-THG-BF008

18

400

400

70

18

88

99%

CS-THG-BF009

18

500

450

75

18

93

99%

CS-THG-BF010

20

250

300

50

20

70

99%

CS-THG-BF011

20

300

350

60

20

80

99%

CS-THG-BF012

20

400

400

70

20

90

99%

CS-THG-BF013

25

400

400

70

25

95

99%

CS-THG-BF014

25

500

450

75

25

100

99%

CS-THG-BF015

25

600

500

80

25

105

99%

CS-THG-BF016

30

600

400

70

30

100

99%

CS-THG-BF017

30

700

450

75

30

105

99%

CS-THG-BF018

30

800

500

80

30

110

99%

| Sic Heating Element Type | OD / mm | Heating zone length / mm | Cold zone length / mm | Range of resistance / Ω | Purity |

| CS-THG-BC001 | 14 | 200 | 250 | 1.2-1.3 | 99% |

| CS-THG-BC002 | 14 | 250 | 250 | 1.5-3.0 | 99% |

| CS-THG-BC003 | 14 | 300 | 250 | 1.8-3.5 | 99% |

| CS-THG-BC004 | 14 | 400 | 350 | 2.3-4.7 | 99% |

| CS-THG-BC005 | 14 | 500 | 350 | 2.9-5.9 | 99% |

| CS-THG-BC006 | 16 | 200 | 200 | 0.9-1.9 | 99% |

| CS-THG-BC007 | 16 | 250 | 200 | 1.2-2.4 | 99% |

| CS-THG-BC008 | 16 | 300 | 300 | 1.4-2.8 | 99% |

| CS-THG-BC009 | 18 | 250 | 250 | 0.9-1.8 | 99% |

| CS-THG-BC010 | 18 | 300 | 350 | 1.1-2.2 | 99% |

| CS-THG-BC011 | 18 | 400 | 250 | 1.4-2.9 | 99% |

| CS-THG-BC012 | 18 | 500 | 350 | 1.8-3.6 | 99% |

| CS-THG-BC013 | 20 | 200 | 200 | 0.6-1.2 | 99% |

| CS-THG-BC014 | 20 | 250 | 250 | 0.7-1.4 | 99% |

| CS-THG-BC015 | 20 | 300 | 300 | 0.8-1.6 | 99% |

| CS-THG-BC016 | 20 | 400 | 350 | 1.1-2.2 | 99% |

| CS-THG-BC017 | 20 | 500 | 400 | 1.4-2.8 | 99% |

| CS-THG-BC018 | 20 | 600 | 350 | 1.5-3.0 | 99% |

| CS-THG-BC019 | 25 | 300 | 400 | 0.6-1.3 | 99% |

| CS-THG-BC020 | 25 | 400 | 400 | 0.8-1.7 | 99% |

| CS-THG-BC021 | 25 | 500 | 400 | 1.1-2.2 | 99% |

| CS-THG-BC022 | 25 | 600 | 500 | 1.3-2.6 | 99% |

| CS-THG-BC023 | 25 | 800 | 450 | 1.7-3.4 | 99% |

| CS-THG-BC024 | 25 | 900 | 400 | 1.9-3.8 | 99% |

| CS-THG-BC025 | 25 | 1000 | 500 | 2.2-4.5 | 99% |

| CS-THG-BC026 | 30 | 400 | 400 | 0.5-0.9 | 99% |

| CS-THG-BC027 | 30 | 500 | 400 | 0.6-1.2 | 99% |

| CS-THG-BC028 | 30 | 1000 | 500 | 1.1-2.2 | 99% |

| CS-THG-BC029 | 30 | 1200 | 500 | 1.3-2.6 | 99% |

| CS-THG-BC030 | 30 | 1300 | 500 | 1.4-2.9 | 99% |

| CS-THG-BC031 | 30 | 1500 | 250 | 1.6-3.4 | 99% |

| CS-THG-BC032 | 30 | 1500 | 300 | 1.6-3.4 | 99% |

| CS-THG-BC033 | 30 | 1500 | 600 | 1.6-3.4 | 99% |

| CS-THG-BC034 | 30 | 2000 | 650 | 2.2-4.4 | 99% |

| CS-THG-BC035 | 35 | 400 | 400 | 0.4-0.8 | 99% |

| CS-THG-BC036 | 35 | 500 | 400 | 0.5-1.0 | 99% |

| CS-THG-BC037 | 35 | 1000 | 500 | 1.0-2.0 | 99% |

| CS-THG-BC038 | 35 | 1200 | 500 | 1.1-2.2 | 99% |

| CS-THG-BC039 | 35 | 1500 | 500 | 1.4-2.8 | 99% |

| CS-THG-BC040 | 40 | 400 | 400 | 0.3-0.7 | 99% |

| CS-THG-BC041 | 40 | 1000 | 500 | 0.8-1.7 | 99% |

| CS-THG-BC042 | 40 | 1500 | 500 | 1.3-2.6 | 99% |

| CS-THG-BC043 | 40 | 2000 | 650 | 1.7-3.4 | 99% |

| CS-THG-BC044 | 40 | 2400 | 700 | 2.0-4.0 | 99% |

| CS-THG-BC045 | 40 | 2600 | 850 | 2.2-4.4 | 99% |

1.Standard Test Method for Determination of the Resistance of Silicon Carbide Heating Rods.

2. Standard Test Method for Determination of the Thermal Conductivity of Silicon Carbide Heating Rods.

3. Standard Test Method for Determination of the Dielectric Strength of Silicon Carbide Heating Rods.

4. Standard Test Method for Determination of the Maximum Temperature of Silicon Carbide Heating Rods.

5. Standard Test Method for Determination of the Breaking Strength of Silicon Carbide Heating Rods.

6. Standard Test Method for Determination of the Electrical Insulation Resistance of Silicon Carbide Heating Rods.

7. Standard Test Method for Determination of the Corrosion Resistance of Silicon Carbide Heating Rods.

8. Standard Test Method for Determination of the Thermal Shock Resistance of Silicon Carbide Heating Rods.

CS’s Silicon Carbide Products are carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

1, silicon carbide rod texture hard and brittle, subject to severe vibration and impact easy to fracture. Therefore, extra care should be taken during transportation and handling should be handled lightly.

2. The length of the heating part of the silicon carbide rod should be equal to the width of the furnace. If the heating part extends into the furnace wall, it is easy to burn the furnace wall.

3. The length of the cold end of the silicon carbide rod should be equal to the thickness of the furnace wall plus the length of the cold end extension of the wall. Generally, the extension length of the cold end is 50 ~ 150mm, so as to cool the cold end and the connection fixture.

4. The inner diameter of the furnace through the silicon carbide rod should be 1.4 ~ 1.6 times the outer diameter of the cold end. The furnace hole is too small or the filling in the hole is too tight, and the high temperature will hinder the free expansion of the silicon carbide rod and cause the broken rod. When installed, the silicon carbide rod should be able to rotate 360 degrees freely.

1.Silicon carbide heating rods are a popular option for many OEM applications due to their high thermal conductivity, resistance to oxidation, and excellent electrical resistance.

2.They are also extremely durable and offer excellent thermal shock and abrasion resistance.

3.Silicon carbide heating rods are often used in applications such as industrial furnaces, power electronics, and automotive components.

4.These heating rods are available in a variety of shapes and sizes, and can be customized to meet the specific needs of your application.

5.For OEM applications, our experienced engineers can provide a tailored solution to meet your exact requirements.

FAQ

1.Q: What is a silicon carbide heating rod?

A: A silicon carbide heating rod is a type of heating element used in many industrial and commercial applications. It is made of high-grade pure silicon carbide and is used to heat air, liquids, and other substances. The rod is highly efficient and can withstand high temperatures. It is also resistant to corrosion and wear and tear.

2.Q: What are the advantages of using a silicon carbide heating rod?

A: The main advantage of using a silicon carbide heating rod is its superior heat transfer capabilities. It is also very durable and can withstand extreme temperatures without breaking down or becoming damaged. Additionally, it is more energy efficient than other types of heating elements and is able to provide consistent and reliable heat.

3.Q: Are there any safety precautions that should be taken when using a silicon carbide heating rod?

A: Yes, it is important to read and follow all safety instructions that come with the rod. It is also important to make sure that the rod is properly wired and connected to the power source. Additionally, the rod should be inspected regularly to ensure that it is in good condition and that there are no signs of wear or damage.

Previous:

Spiral Sic Heating ElementNext :

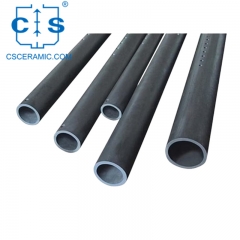

Square Silicon Carbide Beam Tube Silicon carbide Pipe ends open

Silicon carbide Pipe ends open

Silicon carbide tube is a non-metallic component refined from high purity green silicon carbide.Widely used in ceramics, rare earth chemicals, electronic components and other industries.

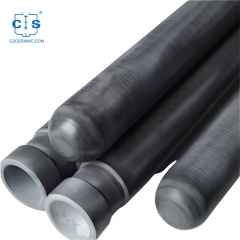

Silicon Carbide Thermocouple Protection Tube with One end Closed

Silicon Carbide Thermocouple Protection Tube with One end Closed

Silicon carbide(RSiC) thermocouple protection tube is anon-metallic component refined from high purity green silicon carbide. Widely used in ceramics, rare earth chemicals, electronic components and other industries.

Spiral Sic Heating Element

Spiral Sic Heating Element

SiC heating element, for high temperatue furnaces, can be used in air, vacuum and other protection gas enviroments.

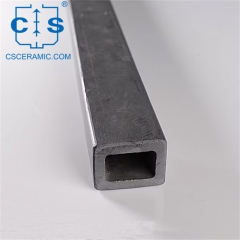

Square Silicon Carbide Beam Tube

Square Silicon Carbide Beam Tube

Silicon carbide beam, used as kiln furniture, are mainly made by SiSiC or RBSiC. SiC beams are widely used for the loading structure system of tunnel kiln, shuttle kiln and other kilns.

SiC Beams High-Temp Load-Bearing Oxidation-Resistant Kiln Furniture for Kilns

SiC Beams High-Temp Load-Bearing Oxidation-Resistant Kiln Furniture for Kilns

SiC Beams, ideal kiln furniture for tunnels, shuttles, double-rollers, & other industrial kilns, feature high-temp load-bearing, oxidation resistance, long lifespan, & energy savings.

Strong Oxidation Resistant SiC Air Cooling Tube for Roller Kilns

Strong Oxidation Resistant SiC Air Cooling Tube for Roller Kilns

The SiC air cooling tube, featuring strong oxidation resistance, durability against thermal shock, low CTE, and no deformation over time, is primarily used in roller kiln cooling zones with a lifespan 10+ times longer than stainless steel pipes.

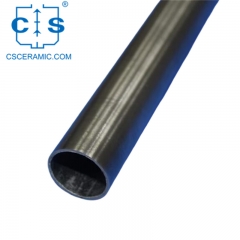

SiC Roller Tube Core Tool for Supporting & Transporting in Refractory Kiln

SiC Roller Tube Core Tool for Supporting & Transporting in Refractory Kiln

SiC roller tubes, essential refractory kiln tools, support and convey ceramic bodies and products in roller kilns and dryers, serving as the core component of roller furnaces.

High-Purity SSiC Protection Tube Pressureless Sintered for Furnaces & Industries

High-Purity SSiC Protection Tube Pressureless Sintered for Furnaces & Industries

High-purity SSiC protection tube, sintered at 2100-2200°C, offers high strength, hardness, and corrosion resistance, used in furnaces, ceramics, glass, chemicals, metal smelting.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522