Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read Moreitem no. :

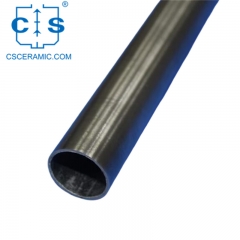

CS-THG-G1001Port :

Any ports of Chinalead date :

5-7 daysMaterial : Silicon Carbide

Purity : 92%~99%

Shape : Round

Original Country : Made in China

1. The special wear resistance of silicon carbide protection tube is 1.5 times that of tungsten carbide.

2. Silicon carbide protective tube with corrosion resistance, acid and alkali corrosion products, is an ideal substitute for domestic chemical industry.

3. Silicon carbide protection tube can withstand 3000 degrees of high temperature without significantly reducing the strength of the material.

4. Silicon carbide protection tube has good thermal shock resistance.

5. The high thermal conductivity of silicon carbide protection tube is five times that of stainless steel.

PROPERTIES

UNIT

VALUE

Color

/

Gray

Hardness

Mohs

9.5

Density

g/cm3

3

Thermal conductivity at

Btu/fthF @300℃

50

Compressive Strength

PSI

500,000

Flexural Strength

PSI

70,000

Max service temperature

℃

1600

Linear Coe. Of thermal Expansion (25C-600C)

10-6/℃

4

Item

OD (mm)

ID(mm)

Purity

CS-THG-G1001

20

10

99%

CS-THG-G1002

20

8

99%

CS-THG-G1003

25

15

99%

CS-THG-G1004

25

13

99%

CS-THG-G1005

30

20

99%

CS-THG-G1006

30

18

99%

CS-THG-G1007

35

25

99%

CS-THG-G1008

35

23

99%

CS-THG-G1009

40

30

99%

CS-THG-G1010

40

26

99%

CS-THG-G1011

45

35

99%

CS-THG-G1012

50

40

99%

CS-THG-G1013

50

35

99%

CS-THG-G1014

55

45

99%

CS-THG-G1015

60

50

99%

CS-THG-G1016

60

40

99%

CS-THG-G1017

70

25

99%

CS-THG-G1018

90

63

99%

CS-THG-G1019

100

73

99%

CS-THG-G1020

110

80

99%

CS-THG-G1021

119

99

99%

CS-THG-G1022

120

95

99%

CS-THG-G1023

133

105

99%

CS-THG-G1024

155

130

99%

CS-THG-G1025

168

140

99%

CS-THG-G1026

273

243

99%

CS-THG-G1027

280

230

99%

CS-THG-G2001

22

12

99%

CS-THG-G2002

28

18

99%

CS-THG-G2003

32

10

99%

CS-THG-G2004

38

28

99%

CS-THG-G2005

42

32

99%

CS-THG-G2006

47

37

99%

CS-THG-G2007

56

46

99%

CS-THG-G2008

55

45

99%

CS-THG-G2009

68

56

99%

CS-THG-G2010

40

20

99%

CS-THG-G2011

30

18

99%

CS-THG-G2012

40

25

99%

CS-THG-G2013

30

18

99%

CS-THG-G2014

40

40

99%

CS-THG-G2015

70

25

99%

CS-THG-G2016

70

30

99%

CS-THG-G2017

90

63

99%

CS-THG-G2018

105

70

99%

CS-THG-G2019

104

82

99%

CS-THG-G2020

120

100

99%

CS-THG-G2021

115

90

99%

CS-THG-G2022

128

90

99%

CS-THG-G2023

150

140

99%

CS-THG-G2024

170

140

99%

CS-THG-G2025

270

240

99%

CS-THG-G2026

285

235

99%

CS-THG-G2027

22

10

99%

CS-THG-G2028

25

13

99%

CS-THG-G2029

30

18

99%

CS-THG-G2030

35

23

99%

CS-THG-G2031

40

26

99%

CS-THG-G2032

50

35

99%

CS-THG-G2033

60

40

99%

(1) Acid and alkali resistance: in acid resistance, alkali resistance, oxidation resistance, silicon carbide due to the protective film of silica, acid resistance is strong, alkali resistance is slightly poor.

(2) Anti-oxidation: when the silicon carbide material is heated to 1300 ° C in the air, the silicon carbide crystal surface begins to form a protective layer of silica.

(3)With the thickening of the protective layer, the continued oxidation of the internal silicon carbide is prevented, so that the silicon carbide has better oxidation resistance.

(4)When the temperature reaches 1900K(1627℃) above, the protective film of silica begins to be destroyed, and the oxidation of silicon carbide is aggravated, so 1900K is the high working temperature of silicon carbide in the atmosphere containing oxidants.

1. 5-50 pieces in a wooden box (fully enclosed, safe, and secure)

2.800kg~1000kg /wooden box.

3. Anti-collision protection such as foam board The 4.3-layer wood composite panel is sturdy, impact resistant, drop resistant.

4.Professional car transport to various ports in China, then loaded by professional shipping company.

5. Competitive sea freight and short transit time.

1. If there are drawings, please send drawings (CAD,PDF, hand sketch), etc.

2. Specify the size, quantity, thickness and other specifications.

3. Determine the processing technology (simple cutting, drilling, to map custom parts, grinding, milling saw cutting.

4. Pay according to the actual quotation.

Note: If the size requirements are particularly accurate, please explain to customer service. Because there are certain tolerances in normal process standards such as cutting, grinding and drilling, please explain in advance if there are precision requirements for irregular parts.

As a professional industrial ceramic supplier, we have a series of advantages that guarantee our market share in the international trade market.

1.Reliable quality control, complete specifications, support customization of non-standard products.

2.Professional and committed service team.

3.Multiple protection of packaging, secure and reliable.

4.Highly efficient delivery channel, safe and rest-assured.

Q1: What types of furnaces can a silicon carbide crucible be used in?

A1: Silicon carbide crucibles are primarily used in electric resistance furnaces, induction furnaces, and ceramic kilns. They are also used in certain types of gas-fired furnaces and in certain types of torch melting operations.

Q2: What types of metals can be melted in a silicon carbide crucible?

A2: Silicon carbide crucibles are best suited to melting non-ferrous metals such as aluminum, copper, brass, silver, and gold. They can also be used to melt ferrous metals such as iron and steel, but they require higher temperatures and more precise control of the melting process.

Q3: What are the advantages of using a silicon carbide crucible?

A3: Silicon carbide crucibles offer several advantages over other types of crucibles. They are capable of withstanding extremely high temperatures and are highly corrosion-resistant. They are also lightweight and easy to handle. Additionally, they are very durable and can be used multiple times.

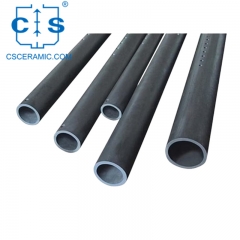

Silicon carbide Pipe ends open

Silicon carbide Pipe ends open

Silicon carbide tube is a non-metallic component refined from high purity green silicon carbide.Widely used in ceramics, rare earth chemicals, electronic components and other industries.

U-Type Sic Spiral Heating Element Rod

U-Type Sic Spiral Heating Element Rod

SiC heating element is widely used in high temperatue furnaces. It can be used in air, vacuum and other protection gas enviroments.

Spiral Sic Heating Element

Spiral Sic Heating Element

SiC heating element, for high temperatue furnaces, can be used in air, vacuum and other protection gas enviroments.

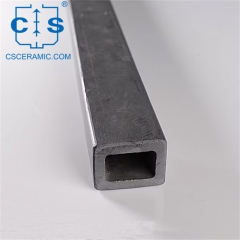

Square Silicon Carbide Beam Tube

Square Silicon Carbide Beam Tube

Silicon carbide beam, used as kiln furniture, are mainly made by SiSiC or RBSiC. SiC beams are widely used for the loading structure system of tunnel kiln, shuttle kiln and other kilns.

SiC Beams High-Temp Load-Bearing Oxidation-Resistant Kiln Furniture for Kilns

SiC Beams High-Temp Load-Bearing Oxidation-Resistant Kiln Furniture for Kilns

SiC Beams, ideal kiln furniture for tunnels, shuttles, double-rollers, & other industrial kilns, feature high-temp load-bearing, oxidation resistance, long lifespan, & energy savings.

Strong Oxidation Resistant SiC Air Cooling Tube for Roller Kilns

Strong Oxidation Resistant SiC Air Cooling Tube for Roller Kilns

The SiC air cooling tube, featuring strong oxidation resistance, durability against thermal shock, low CTE, and no deformation over time, is primarily used in roller kiln cooling zones with a lifespan 10+ times longer than stainless steel pipes.

SiC Roller Tube Core Tool for Supporting & Transporting in Refractory Kiln

SiC Roller Tube Core Tool for Supporting & Transporting in Refractory Kiln

SiC roller tubes, essential refractory kiln tools, support and convey ceramic bodies and products in roller kilns and dryers, serving as the core component of roller furnaces.

High-Purity SSiC Protection Tube Pressureless Sintered for Furnaces & Industries

High-Purity SSiC Protection Tube Pressureless Sintered for Furnaces & Industries

High-purity SSiC protection tube, sintered at 2100-2200°C, offers high strength, hardness, and corrosion resistance, used in furnaces, ceramics, glass, chemicals, metal smelting.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522