Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

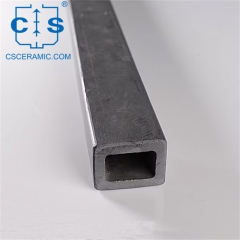

Read MoreSilicon carbide beam, used as kiln furniture, are mainly made by SiSiC or RBSiC. SiC beams are widely used for the loading structure system of tunnel kiln, shuttle kiln and other kilns.

item no. :

CS-THG-H001Color :

BlackPort :

Shenzhen China, Express deliverylead date :

Within one monthMaterial : Silicon Carbide

Purity : 95%

Shape : Square

Original Country : China

Silicon Carbide Beam Features

1.Squae Silicon Carbide (SiC) Beam Tubes are a type of beam tube that is made out of silicon carbide.

2.They are designed to provide superior strength and durability compared to traditional steel beam tubes.

3.They are lightweight, corrosion-resistant, and have excellent thermal and electrical properties.

4.These beam tubes are often used in high temperature and high pressure applications such as furnaces, boilers, power plants, and aerospace components.

5.They can also be used in applications where there is a need for a high temperature and pressure barrier.

Beam Tube Applications

1.Silicon carbide beams are used in a variety of applications, including semiconductor wafer processing, high temperature furnaces, thermal insulation, semiconductor processing, and more.

2.They are also used in aerospace and defense applications, such as fuel cell components, high temperature bearings, and engine components.

3.Silicon carbide beams are also used in medical applications, such as prosthetic implants, and in industrial applications such as abrasives.

4.3Silicon carbide beams are also used in power electronics, such as solar cells and wind turbines, as well as in automotive and transportation applications, such as brake discs, clutches, and suspension components.

Sic Beam Propeties

Item

Unit

Data

Operating Temperature

℃

1380

Density

g/cm³

≥3.02

Porosity

%

< 0.1

Bending Strength

Mpa

250(20℃)

Mpa

280 (1200℃)

Elastic Modulus

Gpa

330(20℃)

Gpa

300 (1200℃)

Thermal Conductivity

W/m.k

45 (1200℃)

Thermal Expansion Coefficient

K-1×10-6

4.5

Mohs Hardness

/

13

Alkalinity and Acidity

/

Excellent

| Item | Cut side height(mm) | Thickness(mm) | Length (mm) | Purity(%) |

| CS-THG-H001 | 20 | 4 | 50-4500 | 95 |

| CS-THG-H002 | 20 | 5 | 50-4500 | 95 |

| CS-THG-H003 | 20 | 4 | 50-4500 | 95 |

| CS-THG-H004 | 20 | 5 | 50-4500 | 95 |

| CS-THG-H005 | 20 | 5 | 50-4500 | 95 |

| CS-THG-H006 | 25 | 5 | 50-2000 | 95 |

| CS-THG-H007 | 25 | 5 | 50-4500 | 95 |

| CS-THG-H008 | 30 | 4 | 50-4500 | 95 |

| CS-THG-H009 | 30 | 5 | 50-4500 | 90 |

| CS-THG-H010 | 30 | 4 | 50-4500 | 95 |

| CS-THG-H011 | 30 | 5 | 50-4500 | 95 |

| CS-THG-H012 | 30 | 6 | 50-4500 | 95 |

| CS-THG-H013 | 30 | 4 | 50-4500 | 95 |

| CS-THG-H014 | 30 | 5 | 50-4500 | 95 |

| CS-THG-H015 | 30 | 6 | 50-4500 | 95 |

| CS-THG-H016 | 30 | 5 | 50-4500 | 90 |

| CS-THG-H017 | 30 | 6 | 50-4500 | 95 |

| CS-THG-H018 | 45 | 4 | 50-4500 | 95 |

| CS-THG-H019 | 45 | 5 | 50-4500 | 95 |

| CS-THG-H020 | 45 | 6 | 50-4500 | 95 |

| CS-THG-H021 | 40 | 5 | 50-4500 | 95 |

| CS-THG-H022 | 40 | 6 | 50-4500 | 95 |

| CS-THG-H023 | 40 | 7 | 50-4500 | 95 |

| CS-THG-H024 | 40 | 6 | 50-4500 | 95 |

| CS-THG-H025 | 40 | 7 | 50-4500 | 95 |

| CS-THG-H026 | 40 | 5 | 50-4500 | 95 |

| CS-THG-H027 | 40 | 6 | 50-4500 | 95 |

| CS-THG-H028 | 40 | 7 | 50-4500 | 95 |

| CS-THG-H029 | 45 | 5 | 50-4500 | 95 |

| CS-THG-H030 | 45 | 6 | 50-4500 | 95 |

| CS-THG-H031 | 45 | 7 | 50-4500 | 95 |

| CS-THG-H032 | 50 | 5 | 50-4500 | 95 |

| CS-THG-H033 | 50 | 6 | 50-4500 | 95 |

| CS-THG-H034 | 50 | 7 | 50-4500 | 95 |

| CS-THG-H035 | 50 | 6 | 50-4500 | 95 |

| CS-THG-H036 | 50 | 7 | 50-4500 | 95 |

| CS-THG-H037 | 50 | 8 | 50-4500 | 95 |

| CS-THG-H038 | 50 | 6 | 50-4500 | 95 |

| CS-THG-H039 | 50 | 7 | 50-4500 | 95 |

| CS-THG-H040 | 50 | 8 | 50-4500 | 95 |

| CS-THG-H041 | 60 | 7 | 50-4500 | 95 |

| CS-THG-H042 | 60 | 8 | 50-4500 | 95 |

| CS-THG-H043 | 60 | 9 | 50-4500 | 95 |

| CS-THG-H044 | 60 | 7 | 50-4500 | 95 |

| CS-THG-H045 | 60 | 8 | 50-4500 | 95 |

| CS-THG-H046 | 60 | 9 | 50-4500 | 95 |

| CS-THG-H047 | 60 | 7 | 50-4500 | 95 |

| CS-THG-H048 | 60 | 8 | 50-4500 | 95 |

| CS-THG-H049 | 60 | 9 | 50-4500 | 95 |

| CS-THG-H050 | 60 | 7 | 50-4500 | 95 |

| CS-THG-H051 | 60 | 8 | 50-4500 | 95 |

| CS-THG-H052 | 60 | 9 | 50-4500 | 95 |

| CS-THG-H053 | 70 | 7 | 50-4500 | 95 |

| CS-THG-H054 | 70 | 8 | 50-4500 | 95 |

| CS-THG-H055 | 70 | 9 | 50-4500 | 95 |

| CS-THG-H056 | 50 | 5 | 50-4000 | 95 |

| CS-THG-H057 | 60 | 6 | 50-4000 | 95 |

| CS-THG-H058 | 70 | 7 | 50-4000 | 95 |

| Item | Cut side height(mm) | Thickness(mm) | Length (mm) | Purity(%) |

| CS-THG-H001 | 20 | 4 | 50-4500 | 95 |

| CS-THG-H002 | 20 | 5 | 50-4500 | 95 |

| CS-THG-H003 | 20 | 4 | 50-4500 | 95 |

| CS-THG-H004 | 20 | 5 | 50-4500 | 95 |

| CS-THG-H005 | 20 | 5 | 50-4500 | 95 |

| CS-THG-H006 | 25 | 5 | 50-2000 | 95 |

| CS-THG-H007 | 25 | 5 | 50-4500 | 95 |

| CS-THG-H008 | 30 | 4 | 50-4500 | 95 |

| CS-THG-H009 | 30 | 5 | 50-4500 | 90 |

| CS-THG-H010 | 30 | 4 | 50-4500 | 95 |

| CS-THG-H011 | 30 | 5 | 50-4500 | 95 |

| CS-THG-H012 | 30 | 6 | 50-4500 | 95 |

| CS-THG-H013 | 30 | 4 | 50-4500 | 95 |

| CS-THG-H014 | 30 | 5 | 50-4500 | 95 |

| CS-THG-H015 | 30 | 6 | 50-4500 | 95 |

| CS-THG-H016 | 30 | 5 | 50-4500 | 90 |

| CS-THG-H017 | 30 | 6 | 50-4500 | 95 |

| CS-THG-H018 | 45 | 4 | 50-4500 | 95 |

| CS-THG-H019 | 45 | 5 | 50-4500 | 95 |

| CS-THG-H020 | 45 | 6 | 50-4500 | 95 |

| CS-THG-H021 | 40 | 5 | 50-4500 | 95 |

| CS-THG-H022 | 40 | 6 | 50-4500 | 95 |

| CS-THG-H023 | 40 | 7 | 50-4500 | 95 |

| CS-THG-H024 | 40 | 6 | 50-4500 | 95 |

| CS-THG-H025 | 40 | 7 | 50-4500 | 95 |

| CS-THG-H026 | 40 | 5 | 50-4500 | 95 |

| CS-THG-H027 | 40 | 6 | 50-4500 | 95 |

| CS-THG-H028 | 40 | 7 | 50-4500 | 95 |

| CS-THG-H029 | 45 | 5 | 50-4500 | 95 |

| CS-THG-H030 | 45 | 6 | 50-4500 | 95 |

| CS-THG-H031 | 45 | 7 | 50-4500 | 95 |

| CS-THG-H032 | 50 | 5 | 50-4500 | 95 |

| CS-THG-H033 | 50 | 6 | 50-4500 | 95 |

| CS-THG-H034 | 50 | 7 | 50-4500 | 95 |

| CS-THG-H035 | 50 | 6 | 50-4500 | 95 |

| CS-THG-H036 | 50 | 7 | 50-4500 | 95 |

| CS-THG-H037 | 50 | 8 | 50-4500 | 95 |

| CS-THG-H038 | 50 | 6 | 50-4500 | 95 |

| CS-THG-H039 | 50 | 7 | 50-4500 | 95 |

| CS-THG-H040 | 50 | 8 | 50-4500 | 95 |

| CS-THG-H041 | 60 | 7 | 50-4500 | 95 |

| CS-THG-H042 | 60 | 8 | 50-4500 | 95 |

| CS-THG-H043 | 60 | 9 | 50-4500 | 95 |

| CS-THG-H044 | 60 | 7 | 50-4500 | 95 |

| CS-THG-H045 | 60 | 8 | 50-4500 | 95 |

| CS-THG-H046 | 60 | 9 | 50-4500 | 95 |

| CS-THG-H047 | 60 | 7 | 50-4500 | 95 |

| CS-THG-H048 | 60 | 8 | 50-4500 | 95 |

| CS-THG-H049 | 60 | 9 | 50-4500 | 95 |

| CS-THG-H050 | 60 | 7 | 50-4500 | 95 |

| CS-THG-H051 | 60 | 8 | 50-4500 | 95 |

| CS-THG-H052 | 60 | 9 | 50-4500 | 95 |

| CS-THG-H053 | 70 | 7 | 50-4500 | 95 |

| CS-THG-H054 | 70 | 8 | 50-4500 | 95 |

| CS-THG-H055 | 70 | 9 | 50-4500 | 95 |

| CS-THG-H056 | 50 | 5 | 50-4000 | 95 |

| CS-THG-H057 | 60 | 6 | 50-4000 | 95 |

| CS-THG-H058 | 70 | 7 | 50-4000 | 95 |

CS’s Silicon Carbide Products are carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

1, silicon carbide tube texture hard and brittle, thread with limited elasticity, installation and disassembly should be fully careful attention, so as not to break, damage. In any case, it should be guaranteed to expand and contract freely, and the existence of mechanical stress should be avoided.

2.Silicon carbon tube aging, life and the use of temperature is very close, generally at 1300℃±50℃ can run 1500 hours or so.

3, the heating can not contain too high moisture, otherwise it will affect the life of silicon carbon tube, can be dried and then heated.

4, silicon carbon tube is not suitable for working in a protective atmosphere, such as hydrogen. Carbon monoxide will also free the carbon in the case of insufficient oxygen supply, thus affecting the life of the SIC tube.

5, the selection of silicon carbon tube surface load varies with the temperature, the working temperature at 1300℃ allows 6w/cm2, and the working temperature at 1000℃ can allow 30 w/cm2, choose the appropriate heating power can extend the life of silicon carbon tube. 6. Clean the inner and outer furnace tubes before installing the silicon carbon tube. Remove the sundry between the silicon carbide pipe thread strips or can cause short circuit, the conductive clip connecting piece should be rotated tightly, and the insulation piece should be reliably insulated.

7, the installation can be energized oven, starting from low temperature and low power for 8 hours, the oven must be used for a long time before not using, especially in the southern humid areas. 8. The spare silicon carbon tube should be placed in a dry place without atmospheric erosion to prevent the delidification of the aluminum plating end.

Pipe diameter, length of heating end, length of cold end, total length, resistance, service temperature need to be provided 2: link mode and series mode can be provided in detail.

Why Choose US

As a professional industrial ceramic supplier, we have a series of advantages that guarantee our market share in the international trade market.

1.Reliable quality control, complete specifications, support customization of non-standard products.

2.Professional and committed service team.

3.Multiple protection of packaging, secure and reliable.

4.Highly efficient delivery channel, safe and rest-assured.

1. What is silicon carbide beam?

Silicon carbide (SiC) beam is a highly durable, low density solid material made from a combination of silicon and carbon atoms. It is often used in applications such as semiconductor wafers, bearings, and bulletproof armor due to its superior strength and heat resistance. SiC beams are extremely lightweight and have excellent mechanical strength, making them ideal for use in a variety of industrial and consumer applications.

2. How does silicon carbide beam compare to other materials?

Silicon carbide beams offer many advantages over other materials, such as steel and aluminum. SiC beams are much lighter in weight than steel, making them easier to transport and install.

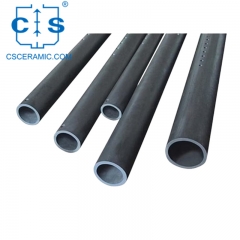

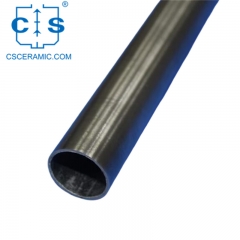

Silicon carbide Pipe ends open

Silicon carbide Pipe ends open

Silicon carbide tube is a non-metallic component refined from high purity green silicon carbide.Widely used in ceramics, rare earth chemicals, electronic components and other industries.

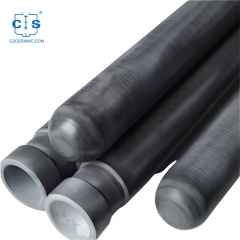

Silicon Carbide Thermocouple Protection Tube with One end Closed

Silicon Carbide Thermocouple Protection Tube with One end Closed

Silicon carbide(RSiC) thermocouple protection tube is anon-metallic component refined from high purity green silicon carbide. Widely used in ceramics, rare earth chemicals, electronic components and other industries.

U-Type Sic Spiral Heating Element Rod

U-Type Sic Spiral Heating Element Rod

SiC heating element is widely used in high temperatue furnaces. It can be used in air, vacuum and other protection gas enviroments.

Spiral Sic Heating Element

Spiral Sic Heating Element

SiC heating element, for high temperatue furnaces, can be used in air, vacuum and other protection gas enviroments.

SiC Beams High-Temp Load-Bearing Oxidation-Resistant Kiln Furniture for Kilns

SiC Beams High-Temp Load-Bearing Oxidation-Resistant Kiln Furniture for Kilns

SiC Beams, ideal kiln furniture for tunnels, shuttles, double-rollers, & other industrial kilns, feature high-temp load-bearing, oxidation resistance, long lifespan, & energy savings.

Strong Oxidation Resistant SiC Air Cooling Tube for Roller Kilns

Strong Oxidation Resistant SiC Air Cooling Tube for Roller Kilns

The SiC air cooling tube, featuring strong oxidation resistance, durability against thermal shock, low CTE, and no deformation over time, is primarily used in roller kiln cooling zones with a lifespan 10+ times longer than stainless steel pipes.

SiC Roller Tube Core Tool for Supporting & Transporting in Refractory Kiln

SiC Roller Tube Core Tool for Supporting & Transporting in Refractory Kiln

SiC roller tubes, essential refractory kiln tools, support and convey ceramic bodies and products in roller kilns and dryers, serving as the core component of roller furnaces.

High-Purity SSiC Protection Tube Pressureless Sintered for Furnaces & Industries

High-Purity SSiC Protection Tube Pressureless Sintered for Furnaces & Industries

High-purity SSiC protection tube, sintered at 2100-2200°C, offers high strength, hardness, and corrosion resistance, used in furnaces, ceramics, glass, chemicals, metal smelting.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522