Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

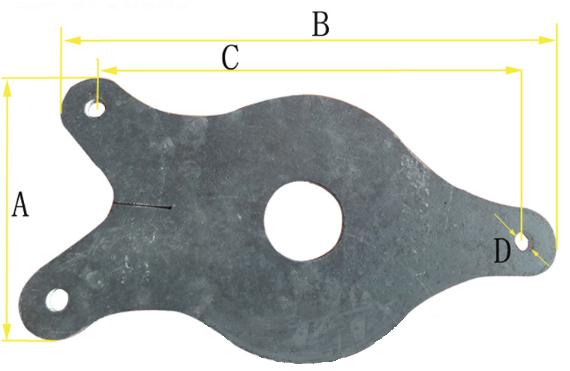

Read Moreitem no. :

CS-THG-B9001Color :

BlackPort :

Shenzhen China, Express deliverylead date :

1-7 daysMaterial : Silicon Carbide

Purity : 90%

Shape : Fish

Original Country : Made in China

Silicon Carbide Fish Shaped Kiln Shelves Ceramic Regualr SiC plates for Firing Dishware

Silicon Carbide Kiln Shelves Features

1.Superior wear resistance, impact resistance and corrosion resistance;

2.Excellent flatness and temperature resistance up to 1380℃;

3.Excellent oxidation resistance;

4.Good dimensional control of complex shapes;

5.Easy installation;

6.Longer service life ( about 5 times more than that of alumina ceramic and 6 times more than that of polyurethane).

Silicon Carbide Fish Shaped Plates Specification

| ITEM | Fish Plate Size Range | A(mm) | B(mm) | C(mm) | D(mm) |

| CS-THG-B9001 | 6 | 165 | 285 | 240 | φ18 |

| CS-THG-B9002 | 6 | 170 | 288 | 238 | φ18 |

| CS-THG-B9003 | 8 | 187 | 363 | 313 | φ18 |

| CS-THG-B9004 | 8 | 195 | 350 | 295 | φ18 |

| CS-THG-B9005 | 8.5 | 200 | 370 | 320 | φ18 |

| CS-THG-B9006 | 9.5 | 220 | 390 | 335 | φ18 |

| CS-THG-B9007 | 10 | 218 | 406 | 350 | φ18 |

| CS-THG-B9008 | 10 | 230 | 405 | 350 | φ18 |

| CS-THG-B9009 | 10.5 | 230 | 410 | 355 | φ18 |

| CS-THG-B9010 | 11 | 230 | 410 | 360 | φ18 |

| CS-THG-B9011 | 12 | 230 | 430 | 400 | φ18 |

| CS-THG-B9012 | 15 | 300 | 460 | 470 | φ18 |

Thickness 7-10mm can be Customized

| Items | SIC brick and tube | SIC burner | SIC path brick | SIC and infrared painting |

| SIC % ≥ | 60-85 | 90 | 85 | 42 |

| Fe2O3 ≤ | 1 | 1 | 1 | / |

| Bulk Density g/cm3 ≥ | 2.3 | 2.5 | 2.5 | |

| Compressive Strength Mpa ≥ | 30 | 50 | 60-80 | |

| Refractoriness °C ≥ | 1500 | 1500 | 1500 | |

| Permanent Linear Change % ≤ | 1400°C 3h 0.5 | 1500°C 3h 0.5 | 1400°C 3h 0.5 | |

| Heat Shock Stability 850°C Water Cooling Times | ≥10 | ≥10 | ≥10 | |

| 0.2Mpa refractoriness under load °C | 1400 | 1500 | 1400 | 1000°C air cooling ≥30 |

Silicon carbide ceramic fish shaped plate is applied in daily ceramic Kiln,sanitary ceramic kiln,electronic ceramic kiln and other kilns.

1.When it can be used in daily ceramic,such as reinforce ceramics, white ceramic and high-class ceramics.

2.Through the burning of 1400°C,it can offer mild,bright and white enamel feeling.

3.When silicon carbide ceramic fish shaped plates can be used in high class washing basin high-class bowl and bowl urinal.

4.Through the burning of 1300°C, SiC plate kiln shelves provides high enamel and high abrasion resistance.It can keep gloss and quality for more than 10 years.

5.Silicon carbide ceramic fish shaped plates are used in electronic ceramic, emery wheel and magnetic material.

Please choose our silicon carbide ceramic fish plates and it can save your using cost,giving you high economic benefit.

2. The placement of sic refractory board should avoid plane stacking, and the upright arrangement method should be adopted.

3. The surface of sic refractory board is sprayed with alumina refractory coating, so it should be placed at the edge of the kiln before use.

4. In order to ensure that the sic refractory board is used for a long time without damage, the fired articles should be placed dry and then installed in the kiln.

5. glaze after the product, contact with the refractory board part of the glaze should be wiped clean.

6. When constructing the refractory board, the refractory pillar should be kept vertical and straight to ensure uniform and smooth stress.

7. The distance of the refractory board should be greater than 15-20mm.

8. The design of the firing curve should be in line with the normal operating conditions, and should not be rapid hot and cold.

9. cooling should be used to cool, avoid the use of cold air rapid cooling, and affect the refractory board.

10. carefully handle the kiln, avoid handling by hand in high temperature, and avoid collision.

SiC Kiln Shelves Fish Plates Packing & Shipping

Silicon Carbide fish plate test standard

1.The test standard for Si Carbide fish plates depends on the type of material and application of the fish plate.

2.Generally, the standard for examination the effectiveness of a angle shell would be supported on ASTM A 370 or ASTM A 617, which provide test methods for the determination of physical science properties of steel products.

3.Other standards such as ASTM A 681 and ASTM A 682 Crataegus oxycantha also be used to test the mechanical properties of a fish plate. 4.Additionally, the monetary standard for non-destructive testing of a angle plate would depend on the type of material and application.

5.ASTM E 23 is a standard for testing the insensibility of metallic materials, which tin be used to test the insensibility of a angle plate.

OEM Requirements

1. If there are drawings, please send drawings (CAD,PDF, hand sketch), etc.

2. Specify the size, quantity, thickness and other specifications.

3. Determine the processing technology (simple cutting, drilling, to map custom parts, grinding, milling saw cutting, etc.).

4. Pay according to the actual quotation.

Note: If the size requirements are particularly accurate, please explain to customer service. Because there are certain tolerances in normal process standards such as cutting, grinding and drilling, please explain in advance if there are precision requirements for irregular parts.

Why Choose Us

As a professional industrial ceramic supplier, we have a series of advantages that guarantee our market share in the international trade market.

1.Reliable quality control, complete specifications, support customization of non-standard products.

2.Professional and committed service team.

3.Multiple protection of packaging, secure and reliable.

4.Highly efficient delivery channel, safe and rest-assured.

FAQ

1.Q: What is the difference between silicon carbide kiln plates and other kiln plates?

A: Silicon carbide kiln plates are more durable and resistant to higher temperatures than other types of kiln plates. They also provide superior thermal shock resistance and are more chemically resistant than other kiln plates.

2. How is silicon carbide kiln plate made?

A:Silicon carbide kiln plate is made by heating a mixture of silicon carbide and other materials such as alumina and magnesia at high temperatures. The resulting material is then pressed into plates and cooled. The plates are then cut to the desired size and shape.

3. What are the benefits of using silicon carbide kiln plates?

A:Silicon carbide kiln plates are known for their high heat resistance, making them ideal for use in high temperature kilns. They are also highly durable and have a low thermal expansion rate, making them ideal for use in industrial applications.

Multiple Shape Silicon Carbide Ceramic Plates

Multiple Shape Silicon Carbide Ceramic Plates

Silicon carbide ceramics are known for their lightweight and high strength, allowing them to provide superior protection from bullets, shrapnel, and other ballistic threats.

NIJ IV Level SiC Ceramic Bulletproof Plate for Armor Lining & Protective Shielding

NIJ IV Level SiC Ceramic Bulletproof Plate for Armor Lining & Protective Shielding

The SiC ceramic bulletproof plate boasts high hardness (HV2600+), NIJ IV-level protection, ideal for body armor lining & vehicle, aircraft, & ship armor.

High-Power SiC Ceramic Substrate Conductive & Semi-Insulating Types

High-Power SiC Ceramic Substrate Conductive & Semi-Insulating Types

SiC substrate, basic material for semiconductor chips, in conductive & semi-insulating types, supports high-temp, high-voltage, large-power apps, available in 2-8 inches (50-200mm) diameters.

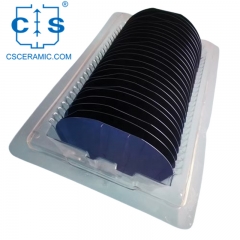

SiC Wafer for MOSFETs, Schottky Diodes, & Photodiodes

SiC Wafer for MOSFETs, Schottky Diodes, & Photodiodes

Silicon carbide wafer, a new-gen semiconductor material, is used to manufacture MOSFETs, Schottky diodes, photodiodes, & other electronic devices.

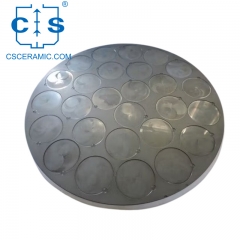

High-Purity SiC Tray for Semiconductor RTA PVD ICP CMP Processes

High-Purity SiC Tray for Semiconductor RTA PVD ICP CMP Processes

The high-purity silicon carbide tray, formed through sintering, serves as a durable carrying device in semiconductor manufacturing processes like RTA, PVD, ICP, and CMP.

High-Speed SOI Wafers Low-Power Silicon-on-Insulator for ICs & MEMS

High-Speed SOI Wafers Low-Power Silicon-on-Insulator for ICs & MEMS

SOI wafers, silicon-on-insulator where a thin layer of silicon sits on an insulating substrate, enable high-speed, low-power operation by reducing capacitance, leakage current, and enhancing switching speeds, widely adopted in microelectronics and emerging in photonics & MEMS.

Graphite Lid equivalent to GB399957 for Netzsch STA 449 DSC 404 TG 209 (Sample covers)

Graphite Lid equivalent to GB399957 for Netzsch STA 449 DSC 404 TG 209 (Sample covers)

85μl φ 6.8 mm Netzsch graphite crucibles for NetzschSTA 449 F1/F3/F5 Jupiter and DSC 404 F1/T3 Pegasus, TG 209 F1 Libra, TG 209 F3 Tarsus Netzsch DSC and TGA measurements. Manufacturer for Netzsch crucibles and sample cups. Netzsch Instruments good alternative DSC sample pans.

Ceramic Sample Pans with cover equivalent to PE-N5200045 PE-N5200040 with lid for PerkinElmer TGA 4000,STA 6000/8000,DSC 4000/6000

Ceramic Sample Pans with cover equivalent to PE-N5200045 PE-N5200040 with lid for PerkinElmer TGA 4000,STA 6000/8000,DSC 4000/6000

STA 6000/TGA 4000 Ceramic sample pans.Alumina crucible for PE N5200040 N5200045.DSC used in all TGA6 series products,including:TGA6, Pyris6TGA, TGA4000 and STA6000 measurements.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522