Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read MoreSilicon carbide mechanical seals are widely used in machinery, petroleum, chemical industry, water treatment, aerospace, ship, metallurgy and nuclear power.

item no. :

CS-THG-J10001Color :

BlackPort :

Shenzhen China, Express deliverylead date :

Within one monthMaterial : Silicon Carbide

Purity : 98.5%

Shape : Round

Original Country : Made in China

SiC Seal Rings Features

1.High temperature resistance:It can be used in high temperature environment (1300 ° C).

2.High hardness:High hardness, wear resistance, and good anti-corrosion performance.

3.High thermal conductivity:High thermal conductivity, which can reduce the temperature of the equipment.

4.High strength:Good strength, toughness and strength can be improved.

5.Good oxidation resistance:It can resist oxidation and is not easy to corrode.

6.Good thermal shock resistance:High thermal shock resistance, which can reduce the frequency of maintenance.

7.Low coefficient of thermal expansion:Low coefficient of thermal expansion, which can reduce the deformation of the equipment.

8.Easy to install:It is easy to install and maintain, and can be customized according to customer requirements.

Sic Ring Applications

1.Silicon carbide seal rings are used in a wide variety of applications, including pumps, valves, compressors, and mixers.

2.These rings are highly resistant to wear and corrosion, making them ideal for many applications.

3.They are also used in applications where high temperatures are present, such as in the oil and gas industry.

4.Silicon carbide seal rings can be used in a variety of shapes and sizes, including standard O-Rings, V-Rings, and T-Rings, as well as custom-made shapes and sizes.

5.They are also used in applications where a high degree of cleanliness is necessary, such as in medical and food processing equipment.

| Item | Inch | OD(mm) | ID(mm) | Thickness | Height | Purity |

| CS-THG-J10001 | 1-150 | 0.5-140 | 0.25-50 | 1-50 | 98.5 | |

| CS-THG-J10002 | 25 | 15 | 5 | 15 | 98.5 | |

| CS-THG-J10003 | 26 | 12 | 2 | 4 | 98.5 | |

| CS-THG-J10004 | 0.750 | 31.60 | 20.49 | 5.56 | 11.11 | 98.5 |

| CS-THG-J10005 | 0.875 | 34.77 | 23.66 | 5.56 | 11.11 | 98.5 |

| CS-THG-J10006 | 1.000 | 37.95 | 26.95 | 5.50 | 12.70 | 98.5 |

| CS-THG-J10007 | 1.125 | 41.12 | 29.92 | 5.60 | 12.70 | 98.5 |

| CS-THG-J10008 | 1.250 | 47.47 | 33.30 | 7.09 | 12.70 | 98.5 |

| CS-THG-J10009 | 1.375 | 50.65 | 36.40 | 7.13 | 12.70 | 98.5 |

| CS-THG-J10010 | 1.500 | 53.82 | 39.57 | 7.13 | 12.70 | 98.5 |

| CS-THG-J10011 | 1.625 | 57.00 | 42.66 | 7.17 | 12.70 | 98.5 |

| CS-THG-J10012 | 1.750 | 60.17 | 46.03 | 7.07 | 12.70 | 98.5 |

| CS-THG-J10013 | 1.875 | 63.35 | 49.20 | 7.08 | 12.70 | 98.5 |

| CS-THG-J10014 | 2.000 | 66.52 | 52.38 | 7.07 | 12.70 | 98.5 |

| CS-THG-J10015 | 2.125 | 69.70 | 55.86 | 6.92 | 14.90 | 98.5 |

| CS-THG-J10016 | 2.250 | 72.87 | 59.03 | 6.92 | 14.90 | 98.5 |

| CS-THG-J10017 | 2.375 | 76.05 | 62.21 | 6.92 | 14.90 | 98.5 |

| CS-THG-J10018 | 2.500 | 79.22 | 65.38 | 6.92 | 15.88 | 98.5 |

| CS-THG-J10019 | 2.625 | 82.40 | 68.63 | 6.89 | 15.88 | 98.5 |

| CS-THG-J10020 | 2.750 | 85.57 | 71.81 | 6.88 | 15.88 | 98.5 |

| CS-THG-J10021 | 2.875 | 88.75 | 74.98 | 6.89 | 15.88 | 98.5 |

| CS-THG-J10022 | 3.000 | 91.92 | 78.16 | 6.88 | 15.88 | 98.5 |

| CS-THG-J10023 | 3.125 | 95.10 | 81.30 | 6.90 | 15.88 | 98.5 |

| CS-THG-J10024 | 3.250 | 98.27 | 84.51 | 6.88 | 15.88 | 98.5 |

| CS-THG-J10025 | 3.375 | 101.45 | 87.68 | 6.89 | 15.88 | 98.5 |

| CS-THG-J10026 | 3.500 | 104.62 | 90.86 | 6.88 | 17.46 | 98.5 |

| CS-THG-J10027 | 3.625 | 107.80 | 94.16 | 6.82 | 17.46 | 98.5 |

| CS-THG-J10028 | 3.750 | 114.15 | 97.33 | 8.41 | 17.46 | 98.5 |

| CS-THG-J10029 | 3.875 | 117.32 | 100.21 | 8.56 | 17.46 | 98.5 |

| CS-THG-J10030 | 4.000 | 120.20 | 103.68 | 8.26 | 17.46 | 98.5 |

1. Heat resistance: The temperature of the sealing surface shall not be lower than the temperature of the medium in the sealed container by more than 10°C.

2. Leakage: The leakage amount shall not be greater than 0.02 ml/min.

3. Pressure resistance: The sealing ring shall not deform and break when the pressure of the sealed container reaches the specified pressure.

4. Wear resistance: The wear amount of the sealing surface of the sealing ring shall not exceed 0.1 mm.

5. Corrosion resistance: The sealing ring shall not be corroded by the medium in the sealed container.

6. Hardness: The hardness of the sealing ring shall not be lower than HRC60.

OEM Service

1.Silicon carbide seal rings are a popular choice for OEMs because of their excellent performance in a variety of demanding applications.

2.They are made from high-performance materials that are resistant to thermal shock and abrasion.

3.Their superior wear resistance makes them ideal for use in high pressure, high temperature applications.

4.They are also highly resistant to corrosion and have excellent mechanical strength.

5.Silicon carbide seal rings are available in a variety of shapes, sizes, and configurations.

6.They can be customized to meet the specific requirements of your application.

To better ensure the safety of your goods,Professional, Environmentally friendly,Convenient and efficient packing services will be provided.

Why Choose Us

As a professional industrial ceramic supplier, we have a series of advantages that guarantee our market share in the

international trade market.

1.Reliable quality control, complete specifications, support customization of non-standard products.

2.Professional and committed service team.

3.Multiple protection of packaging, secure and reliable.

4.Highly efficient delivery channel, safe and rest-assured.

FAQ

1.Q: How are silicon carbide seal rings manufactured?

A: Silicon carbide seal rings are typically machined from a solid block of silicon carbide material. The individual shapes and sizes of the seal rings are cut, shaped, and polished to meet the exact specifications of each application.

2.Q: What types of industries use silicon carbide seal rings?

A: Silicon carbide seal rings are used in a variety of industries including aerospace, automotive, and medical. They are also used in applications that require high temperature, high wear resistance, and excellent chemical resistance.

Previous:

Silicon Carbide Ceramic Gasket Silicon Carbide Ceramic Gasket

Silicon Carbide Ceramic Gasket

Silicon carbide ceramic gaskets are lightweight and can be manufactured in a range of shapes to meet specific sealing requirements.

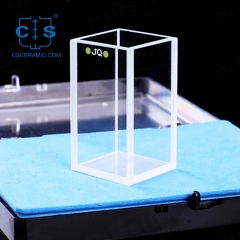

High Purity Quartz Fluorescence Cuvette Light Transmission for Lab Analysis

High Purity Quartz Fluorescence Cuvette Light Transmission for Lab Analysis

Quartz fluorescence cuvette, designed for lab fluorescence analysis, enhancing detection accuracy & sensitivity, and includes a sealed cover to prevent contamination.

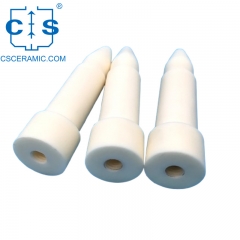

Zirconia Ceramic Positioning Pin for Harsh Environments & Electrical Insulation

Zirconia Ceramic Positioning Pin for Harsh Environments & Electrical Insulation

Premium Zirconia Ceramic Jigs & Fixtures, specifically designed to support, secure, and precisely position workpieces for machining or inspection. These fixtures are engineered to meet the highest standards of precision and reliability, making them an ideal choice for a wide range of industrial applications.

Alumina Ceramic Pin Al2O3 Pin Aluminum Oxide Pin

Alumina Ceramic Pin Al2O3 Pin Aluminum Oxide Pin

The alumina pins are meticulously crafted from high-purity alumina, exhibiting exceptional resistance to high temperatures, corrosion, and wear. These high-performance fasteners are specifically designed to be inserted into holes in components, securely affixing them and playing a crucial role as a vital link between two or more components.

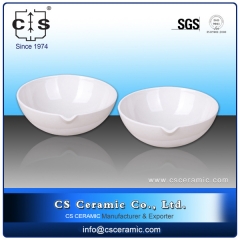

Lab Evaporating Dish Round Bottom with Spout without Handle

Lab Evaporating Dish Round Bottom with Spout without Handle

1. Capacity is from 15ml to 5000ml. 2. Porcelain basins,Round bottom with spout. Labware could satisfied different testing requirement.

Shimadzu Al/ Aluminum Sample Pans with lid D5.7*1.7mm for Shimadzu (DSC Cells)

Shimadzu Al/ Aluminum Sample Pans with lid D5.7*1.7mm for Shimadzu (DSC Cells)

D5.7*1.7mm Shimadzu Aluminum Sample Cells for Shimadzu TDA DSC and TGA measurements. Manufacturer for Shimadzu crucibles and sample cups. Shimadzu Instruments good alternative DSC sample pans.

Black Alumina Rod Al2O3 Ceramic Solid Rod

Black Alumina Rod Al2O3 Ceramic Solid Rod

The black alumina ceramic rod is primarily composed of alumina and is enhanced with a specific proportion of carbon powder, undergoing a unique processing technique to attain its distinctive black hue. This product surpasses traditional alumina rods in terms of electrical insulation, high-temperature resistance, corrosion resistance, and wear resis1

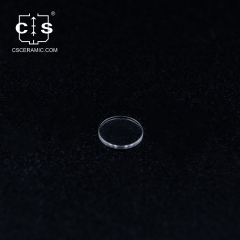

Sapphire disk/disc equivalent to ME-00017759 for Mettler toledo

Sapphire disk/disc equivalent to ME-00017759 for Mettler toledo

Sapphire disk ME-00017759 for Mettler DSC and TGA measurements. Manufacturer for Mettler Toledo crucibles and sample pans. More THERMAL ANALYSIS CONSUMABLES, DSC crucibles are supplied.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522