Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read More

Alumina crucible with high alumina purity,high temperature resistance,good thermal shock, no easy to crack,high slip casting density.

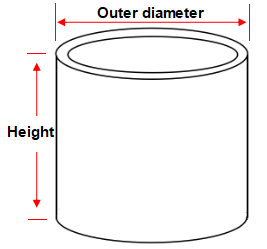

item no. :

CS-OA-191Color :

WhiteMaterial : Alumina ceramic

Volume : : 5-200ml

Shape : Cylindrical

1. High temperature resistance: Long-term use at 1600 ℃, short-term use at 1800 ℃.

2. High caloric shock resistance: The laboratory sintering furnace alumina melting pot is resistant to rapid temperature changes, allowing for quick and safe warming and cooling.

3. Excellent chemical substance stability: The laboratory sintering furnace alumina melting pot is highly resistant to acids, alkalis, and strange corrosive materials.

4. Low caloric conductivity: The laboratory sintering furnace alumina melting pot has a moo thermal conductivity, which allows for more efficient and uniform heating.

1. The laboratory alumina ceramic crucible for sintering furnace is a high-quality and durable vessel designed for use in high-temperature applications.

2. It features a smooth, non-porous surface that ensures consistent results during sintering processes, and helps to prevent contamination of samples.

3. The laboratory alumina ceramic crucible is designed to fit perfectly into sintering furnaces and can withstand high temperatures.

4. With its superior thermal stability, excellent resistance to chemical attack, and high mechanical strength, the laboratory alumina ceramic crucible is a reliable and efficient solution for sintering applications.

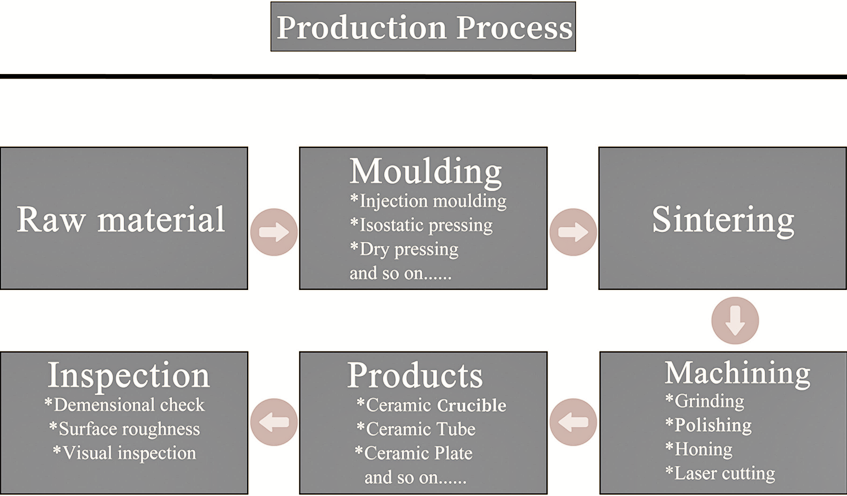

| Cylindrical Alumina crucible (99% ) | |||||||||||

| Item NO. |

Volume

(ml)

|

Outer

diameter

(mm)

|

Height

(mm)

|

Item NO. |

Volume

(ml)

|

Outer

diameter

(mm)

|

Height

(mm)

|

Item NO. |

Volume

(ml)

|

Outer

diameter

(mm)

|

Height

(mm)

|

| CS-AC-070 | 0.5 | 20 | 4 | CS-AC-126 | 40 | 35 | 58 | CS-AC-124-16 | 330 | 75 | 95 |

| CS-AC-071 | 0.7 | 12 | 8 | CS-AC-126-1 | 40 | 50 | 30 | CS-AC-135-1 | 330 | 80 | 80 |

| CS-AC-071-1 | 0.8 | 12 | 12 | CS-AC-110 | 45 | 40 | 50 | CS-AC-158 | 330 | 80 | 80 |

| CS-AC-072 | 0.9 | 12 | 10 | CS-AC-127 | 45 | 42 | 45 | CS-AC-120 | 350 | 80 | 80 |

| CS-AC-073 | 1 | 20 | 5 | CS-AC-127-2 | 45 | 35 | 65 | CS-AC-159 | 350 | 80 | 80 |

| CS-AC-074 | 1 | 12 | 10 | CS-AC-127-3 | 45 | 40 | 50 | CS-AC-159-1 | 350 | 90 | 30 |

| CS-AC-075 | 1 | 18 | 5 | CS-AC-128 | 45 | 35 | 70 | CS-AC-159-2 | 350 | 70 | 120 |

| CS-AC-076 | 1 | 18 | 8 | CS-AC-131-2 | 45 | 50 | 100 | CS-AC-154-4 | 370 | 65 | 150 |

| CS-AC-077 | 1 | 10 | 15 | CS-AC-128-1 | 50 | 40 | 60 | CS-AC-160-5 | 380 | 80 | 100 |

| CS-AC-078 | 1 | 11 | 20 | CS-AC-129 | 50 | 30 | 100 | CS-AC-119-6 | 400 | 85 | 85 |

| CS-AC-079 | 1.5 | 12 | 20 | CS-AC-107 | 55 | 40 | 60 | CS-AC-160 | 400 | 70 | 120 |

| CS-AC-080 | 1.5 | 12 | 25 | CS-AC-130 | 60 | 40 | 70 | CS-AC-160-1 | 400 | 66 | 150 |

| CS-AC-081 | 1.5 | 9 | 40 | CS-AC-131 | 60 | 50 | 50 | CS-AC-160-4 | 400 | 85 | 85 |

| CS-AC-082 | 1.5 | 13 | 25 | CS-AC-132 | 65 | 35 | 100 | CS-AC-161 | 400 | 85 | 85 |

| CS-AC-083 | 2 | 10 | 25 | CS-AC-134 | 75 | 45 | 65 | CS-AC-160-2 | 450 | 90 | 90 |

| CS-AC-083-1 | 2 | 20 | 20 | CS-AC-136 | 80 | 75 | 27 | CS-AC-160-3 | 450 | 90 | 90 |

| CS-AC-085 | 2 | 30 | 5 | CS-AC-134-1 | 80 | 75 | 27 | CS-AC-135-2 | 480 | 90 | 90 |

| CS-AC-086 | 2 | 12 | 39 | CS-AC-135 | 80 | 37 | 69 | CS-AC-162 | 480 | 90 | 90 |

| CS-AC-083-2 | 2.5 | 22 | 20 | CS-AC-137 | 80 | 60 | 40 | CS-AC-124-8 | 500 | 95 | 90 |

| CS-AC-087 | 3 | 18 | 18 | CS-AC-135-4 | 85 | 50 | 60 | CS-AC-160-10 | 500 | 95 | 90 |

| CS-AC-088 | 3 | 16 | 28 | CS-AC-138 | 85 | 50 | 60 | CS-AC-164-1 | 500 | 80 | 130 |

| CS-AC-088-1 | 3 | 12.7 | 25 | CS-AC-135-5 | 90 | 35 | 120 | CS-AC-174-10 | 500 | 80 | 120 |

| CS-AC-088-2 | 3 | 14 | 31 | CS-AC-131-3 | 110 | 50 | 120 | CS-AC-165-10 | 510 | 95 | 95 |

| CS-AC-088-3 | 3 | 15 | 5 | CS-AC-138-1 | 110 | 60 | 60 | CS-AC-124-9 | 550 | 95 | 95 |

| CS-AC-088-5 | 3 | 15 | 20 | CS-AC-138-2 | 110 | 40 | 120 | CS-AC-160-11 | 550 | 95 | 95 |

| CS-AC-089 | 3 | 15 | 75 | CS-AC-119-4 | 115 | 40 | 120 | CS-AC-163 | 600 | 100 | 100 |

| CS-AC-090 | 3 | 10 | 30 | CS-AC-119-5 | 115 | 47 | 85 | CS-AC-164 | 600 | 100 | 100 |

| CS-AC-091 | 3.4 | 17 | 21 | CS-AC-141 | 120 | 90 | 35 | CS-AC-124-15 | 630 | 70 | 210 |

| CS-AC-091-1 | 4 | 14 | 44 | CS-AC-139 | 120 | 50 | 80 | CS-AC-165-11 | 630 | 100 | 100 |

| CS-AC-092 | 4 | 20 | 20 | CS-AC-140 | 120 | 60 | 60 | CS-AC-165 | 650 | 100 | 100 |

| CS-AC-093 | 5 | 32 | 10 | CS-AC-141 | 120 | 90 | 35 | CS-AC-165-2 | 650 | 100 | 100 |

| CS-AC-094 | 5 | 12 | 60 | CS-AC-142 | 125 | 41 | 137 | CS-AC-165-12 | 750 | 88 | 150 |

| CS-AC-094-1 | 5 | 10 | 40 | CS-AC-124-10 | 130 | 60 | 60 | CS-AC-165-5 | 800 | 110 | 100 |

| CS-AC-094-3 | 5 | 11.5 | 50 | CS-AC-131-6 | 130 | 60 | 60 | CS-AC-166 | 800 | 115 | 110 |

| CS-AC-094-4 | 5 | 11.5 | 15 | CS-AC-143 | 130 | 60 | 60 | CS-AC-167 | 800 | 80 | 200 |

| CS-AC-095 | 5 | 11 | 20 | CS-AC-143-1 | 130 | 65 | 45 | CS-AC-135-3 | 880 | 100 | 100 |

| CS-AC-096 | 5 | 10.5 | 20 | CS-AC-143-2 | 130 | 75 | 30 | CS-AC-168 | 880 | 110 | 110 |

| CS-AC-097 | 5 | 20 | 30 | CS-AC-144 | 130 | 45 | 110 | CS-AC-160-6 | 950 | 80 | 250 |

| CS-AC-098 | 5 | 15 | 50 | CS-AC-145 | 130 | 60 | 60 | CS-AC-123-2 | 1000 | 80 | 250 |

| CS-AC-099 | 5 | 28 | 17 | CS-AC-145-1 | 130 | 45 | 110 | CS-AC-168-1 | 1000 | 115 | 155 |

| CS-AC-099-1 | 5 | 35 | 8.5 | CS-AC-084 | 150 | 37 | 175 | CS-AC-169-5 | 1080 | 120 | 120 |

| CS-AC-100 | 5 | 16 | 50 | CS-AC-146 | 150 | 50 | 100 | CS-AC-165-7 | 1100 | 120 | 120 |

| CS-AC-101 | 5 | 54 | 8 | CS-AC-146-1 | 160 | 90 | 35 | CS-AC-169-1 | 1100 | 120 | 120 |

| CS-AC-102 | 5.4 | 17 | 37 | CS-AC-124-5 | 170 | 90 | 35 | CS-AC-160-7 | 1140 | 80 | 300 |

| CS-AC-103 | 6 | 16 | 60 | CS-AC-146-2 | 170 | 70 | 70 | CS-AC-169 | 1140 | 120 | 120 |

| CS-AC-104 | 6 | 17 | 40 | CS-AC-146-3 | 170 | 48 | 120 | CS-AC-124-2 | 1200 | 80 | 300 |

| CS-AC-104-1 | 6 | 16 | 56 | CS-AC-147 | 170 | 65 | 65 | CS-AC-169-6 | 1200 | 110 | 150 |

| CS-AC-105 | 6 | 19 | 35 | CS-AC-160-8 | 175 | 90 | 35 | CS-AC-169-7 | 1200 | 135 | 30 |

| CS-AC-105-1 | 6 | 16 | 80 | CS-AC-148 | 180 | 59 | 87 | CS-AC-169-8 | 1200 | 135 | 110 |

| CS-AC-105-2 | 6 | 20 | 30 | CS-AC-124-11 | 195 | 60 | 90 | CS-AC-165-3 | 1300 | 100 | 200 |

| CS-AC-108 | 7 | 22 | 25 | CS-AC-151 | 200 | 100 | 35 | CS-AC-170 | 1300 | 115 | 155 |

| CS-AC-106 | 8 | 25 | 25 | CS-AC-152 | 200 | 100 | 40 | CS-AC-178 | 1300 | 100 | 200 |

| CS-AC-109 | 9 | 20 | 40 | CS-AC-149 | 200 | 55 | 90 | CS-AC-170-1 | 1400 | 130 | 130 |

| CS-AC-109-1 | 10 | 19 | 58 | CS-AC-149-1 | 200 | 100 | 40 | CS-AC-169-2 | 1450 | 130 | 130 |

| CS-AC-109-2 | 10 | 20 | 50 | CS-AC-149-2 | 200 | 45 | 150 | CS-AC-170-2 | 1450 | 130 | 130 |

| CS-AC-110-1 | 10 | 25 | 30 | CS-AC-150 | 200 | 60 | 100 | CS-AC-165-6 | 1500 | 110 | 195 |

| CS-AC-110-2 | 10 | 30 | 28 | CS-AC-151 | 200 | 100 | 35 | CS-AC-171 | 1500 | 125 | 150 |

| CS-AC-112 | 10 | 19 | 100 | CS-AC-152 | 200 | 100 | 40 | CS-AC-165-8 | 1800 | 120 | 200 |

| CS-AC-113 | 10.2 | 22 | 36 | CS-AC-154-2 | 200 | 70 | 70 | CS-AC-171-1 | 1800 | 140 | 140 |

| CS-AC-083-3 | 15 | 30 | 30 | CS-AC-124-12 | 215 | 60 | 100 | CS-AC-169-3 | 1850 | 140 | 140 |

| CS-AC-114 | 15 | 47 | 13 | CS-AC-132-1 | 215 | 70 | 70 | CS-AC-172 | 1850 | 140 | 140 |

| CS-AC-114-1 | 15 | 23 | 60 | CS-AC-153 | 215 | 70 | 70 | CS-AC-173 | 2000 | 135 | 160 |

| CS-AC-115 | 15 | 30 | 30 | CS-AC-124-6 | 220 | 95 | 40 | CS-AC-174 | 2000 | 135 | 200 |

| CS-AC-115-1 | 15 | 47 | 13 | CS-AC-152-1 | 220 | 50 | 150 | CS-AC-174-1 | 2000 | 150 | 80 |

| CS-AC-115-2 | 15 | 30 | 30 | CS-AC-152-2 | 220 | 60 | 120 | CS-AC-174-2 | 2000 | 170 | 165 |

| CS-AC-115-3 | 15 | 30 | 30 | CS-AC-152-3 | 220 | 55 | 120 | CS-AC-180 | 2200 | 100 | 210 |

| CS-AC-116 | 20 | 35 | 35 | CS-AC-131-4 | 225 | 55 | 120 | CS-AC-169-4 | 2250 | 150 | 150 |

| CS-AC-117 | 20 | 25 | 60 | CS-AC-160-9 | 230 | 95 | 40 | CS-AC-173-1 | 2250 | 160 | 160 |

| CS-AC-118 | 20 | 25 | 60 | CS-AC-119-1 | 250 | 60 | 115 | CS-AC-174-11 | 2250 | 150 | 150 |

| CS-AC-118-1 | 20 | 35 | 30 | CS-AC-154 | 250 | 60 | 120 | CS-AC-181 | 2600 | 140 | 200 |

| CS-AC-119 | 20 | 28 | 58 | CS-AC-154-1 | 250 | 90 | 60 | CS-AC-174-3 | 2700 | 150 | 180 |

| CS-AC-119-2 | 25 | 35 | 35 | CS-AC-124-13 | 260 | 60 | 120 | CS-AC-165-9 | 3300 | 130 | 300 |

| CS-AC-121 | 25 | 28 | 58 | CS-AC-165-1 | 260 | 100 | 40 | CS-AC-175 | 3350 | 170 | 170 |

| CS-AC-122 | 30 | 30 | 60 | CS-AC-165-4 | 260 | 105 | 40 | CS-AC-176 | 4000 | 180 | 180 |

| CS-AC-123 | 30 | 36 | 45 | CS-AC-174-6 | 260 | 60 | 120 | CS-AC-174-8 | 5400 | 185 | 240 |

| CS-AC-123-1 | 30 | 40 | 32 | CS-AC-124-14 | 270 | 70 | 90 | CS-AC-174-9 | 5500 | 200 | 200 |

| CS-AC-124 | 30 | 40 | 35 | CS-AC-119-3 | 300 | 90 | 60 | CS-AC-177 | 5500 | 200 | 200 |

| CS-AC-124-1 | 30 | 30 | 60 | CS-AC-131-5 | 300 | 55 | 170 | CS-AC-174-5 | 5700 | 120 | 600 |

| CS-AC-124-3 | 34 | 26 | 82 | CS-AC-155 | 300 | 95 | 60 | CS-AC-174-7 | 6000 | 176 | 280 |

| CS-AC-124-4 | 35 | 40 | 40 | CS-AC-156 | 300 | 70 | 100 | CS-AC-173-2 | 7400 | 220 | 220 |

| CS-AC-125 | 35 | 40 | 40 | CS-AC-156-1 | 300 | 80 | 80 | CS-AC-178-1 | 7400 | 220 | 220 |

| CS-AC-111 | 36 | 40 | 40 | CS-AC-157 | 300 | 80 | 80 | CS-AC-179 | 9700 | 240 | 240 |

| CS-AC-124-7 | 40 | 40 | 50 | CS-AC-154-3 | 320 | 60 | 170 | CS-AC-174-4 | 23000 | 315 | 315 |

OEM/ODM is acceptable. Your goods will be produced exactly according to your drawings or inquiry

1. Material Testing: Laboratory alumina ceramic crucibles are perfect for testing and analyzing the properties of various materials. These crucibles can withstand high temperatures, making them ideal for sintering and annealing.

2. Thermal Analysis: They are often used in thermal analysis applications such as differential thermal analysis (DTA) and thermogravimetric analysis (TGA). They are designed to resist thermal shock and can provide accurate results at high temperatures.

3. Fuel Cell Development: They are used in the development of fuel cells for testing the performance of various fuel cell components. These crucibles can withstand high temperatures and offer excellent chemical stability, making them ideal for fuel cell testing applications.

4. Metallurgy: Alumina ceramic crucibles are utilized in metallurgy applications for melting and casting metal alloys.

5. Powder Processing: Can be used in powder processing applications such as mixing, grinding, and pulverizing. They are also suitable for ball milling and can be used to produce fine powders.

| Item | Test Condition | 95% Al2O3 | 99% Al2O3 | 99.5% Al2O3 | ||

| Physical properties | Density | g/cm3 | >3.6 | 3.89 | 3.96 | |

| Moisture absorption | % | 0 | 0 | 0 | ||

| Mechanical properties | ROHS Hardness | ≥85 | ≥89 | ≥89 | ||

| Flexural strength | psiX103 | 20℃ | 358 | 550 | 550 | |

| Compressive strength | psiX103 | 20℃ | 2068(300) | 2600(377) | 2600(377) | |

| Fracture toughness | Mpa.m3/2 | K(l c) | 4.3 | 5.6 | 6 | |

| Thermal properties | Maximum use temperature | ℃ | 1450 | 1600 | 1650 | |

| Thermal expansion coefficient | 1X10-6/℃ | (25-1000℃) | 7.6 | 7.9 | 8.2 | |

| Thermal shock resistance | ℃ | Tc | 250 | 200 | 200 | |

| Thermal conductivity | w/mok | 20℃ | 16 | 30 | 30.4 | |

| Electrical properties | Volume resistivity | Ohm/cm2 | 100℃ | >1013 | >1014 | >1014 |

| Dielectric breakdown strength | KV/mm | 8.7(220) | 8.7(220) | 8.7(220) | ||

| Dielectric constant | (E) | 1MHz25℃ | 9 | 9.7 | 9.7 | |

| Dielectric constant (100MHz) | (E) | 9.5 | ||||

Q1. What is a laboratory sintering furnace alumina crucible?

A1. A laboratory sintering furnace aluminium oxide melting pot is a ceramic vessel old to make materials during high-temperature processes so much as sintering.

Q2. What are the benefits of laboratory sintering furnace atomic alumina crucible?

A2. The main benefits of using a testing ground sintering furnace aluminum oxide melting toilet are its high temperature resistance, durability, and chemical message inertness. It is also non-porous and tin withstand extreme point temperatures without cracking or breaking.

Q3. What types of materials can be situated in a testing ground sintering furnace alumina crucible?

A3. Testing ground sintering furnace aluminium oxide crucibles can be used to hold a variety usher of materials, including metals, alloys, ceramics, and glass.

Q4. What is the lead time for the alumina ceramic crucible?

A4. The lead time is dependent on the size and quantity required. Please contact us for more information.

1. Wear protective gear much as gloves, goggles, and a face mask before start to clean the testing ground sintering furnace alumina crucible.

2. Use a easy sweep to remove whatever dust from the surface of the crucible.

3. Soak the crucible in a cleanup solution much as diluted hydrochloric acid for several hours.

4. Rinse the crucible with water and dry out it with a soft cloth.

1. Ensure that the aluminium oxide melting pot is free from whatsoever visible defects.

2. Confirm the crucible is made of the correct material and is of the right size.

3. Confirm the temperature uniformity of the crucible and ensure it is within the specified range.

4. Verify that the furnace is able to exert the set temperature for a certain period of time.

5. Test the sintering process to check that the product meets the required quality standards.

1. We offer personalized and customized services to meet your individual needs.

2. We are experienced professionals with a proven track record of success.

3. We provide excellent customer service and timely responses to all inquiries.

4. We have competitive rates and work to ensure that you get the best value for your money.

5. We use the latest technology and tools to ensure that your project is completed to the highest standards.

6. We take pride in our work and strive for complete customer satisfaction.

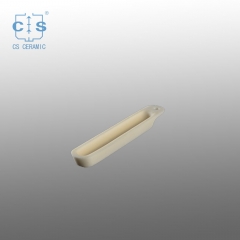

Furnace Alumina Ceramic Combustion Boats

Furnace Alumina Ceramic Combustion Boats

Alumina ceramic combustion boats are available in different sizes and shapes to accommodate various sample, they are a versatile tool for high-temperature applications that require a durable and inert container.

TGA alumina ceramic crucible is a reliable and innovative tool that delivers consistent and precise results in thermal analysis testing.This crucible comes in a variety of and sizes,making it ideal for a range of experimental setups.

Cylindrical Alumina Ceramic Crucible 0.5ml-23000ml

Cylindrical Alumina Ceramic Crucible 0.5ml-23000ml

Cylindrical alumina ceramic crucibles come in a variety of sizes and are widely used in research laboratories, industrial facilities, and educational institutions. The durable nature of alumina ceramic makes them long lasting.

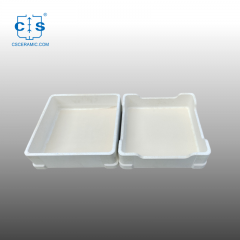

Alumina Ceramic Tray Ceramic Ash Boats for Coal Analysis

Alumina Ceramic Tray Ceramic Ash Boats for Coal Analysis

Alumina ceramic tray ash cone bracket is a high-quality accessory used for holding ash cones on top of alumina trays.It is available in different sizes and shapes and can be used with a variety of ash cone types.

Square Alumina Ceramic Crucible Boat

Square Alumina Ceramic Crucible Boat

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Alumina Ceramic Tray Rectangular Trays

Alumina Ceramic Tray Rectangular Trays

Alumina ceramic tray is inert to hydrogen, carbon and refractory metals, can be used at operating temperatures to 1600°C in both oxidizing and reducing atmospheres. Available in various sizes and shapes.

Alumina Ceramic Mortar and Pestle Sets

Alumina Ceramic Mortar and Pestle Sets

Alumina mortar and pestle has high chemical etching resistance,resistant to sudden cold and hot, un-explosive.Low cost and high efficiency,available in various sizes and shapes.

Short Form of Alumina Ceramic Crucible with Lid

Short Form of Alumina Ceramic Crucible with Lid

Alumina Crucibles with good insulation performance ,Wear resistant performance,refractory and high temperature resistance.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522