How to Choose the Right Alumina Ceramic Furnace Tube for Your Application?

Are you in need of an alumina ceramic furnace tube for your application? Choosing the right one can be crucial for the success of your process. Alumina ceramic tubes offer excellent thermal and chemical resistance, making them ideal for high-temperature applications. In this article, we will guide you through the process of selecting the right alumina ceramic furnace tube that meets your specific requirements.

Introduction: Understanding Alumina Ceramic Furnace Tubes

Alumina ceramic furnace tubes are widely used in various high-temperature applications, such as heat treatment, sintering, and chemical reactions. These tubes are made from alumina (aluminum oxide), which exhibits excellent thermal and chemical resistance properties. Alumina ceramic tubes can withstand extreme temperatures and corrosive environments, making them an ideal choice for industries like chemical processing, metallurgy, and semiconductor manufacturing.

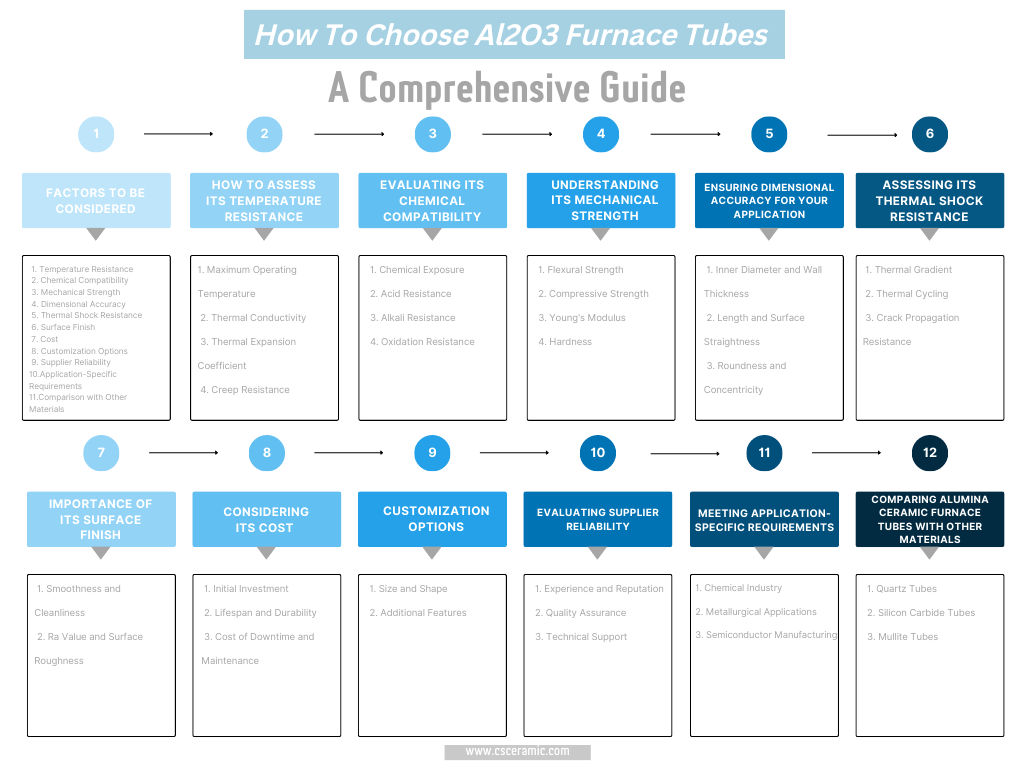

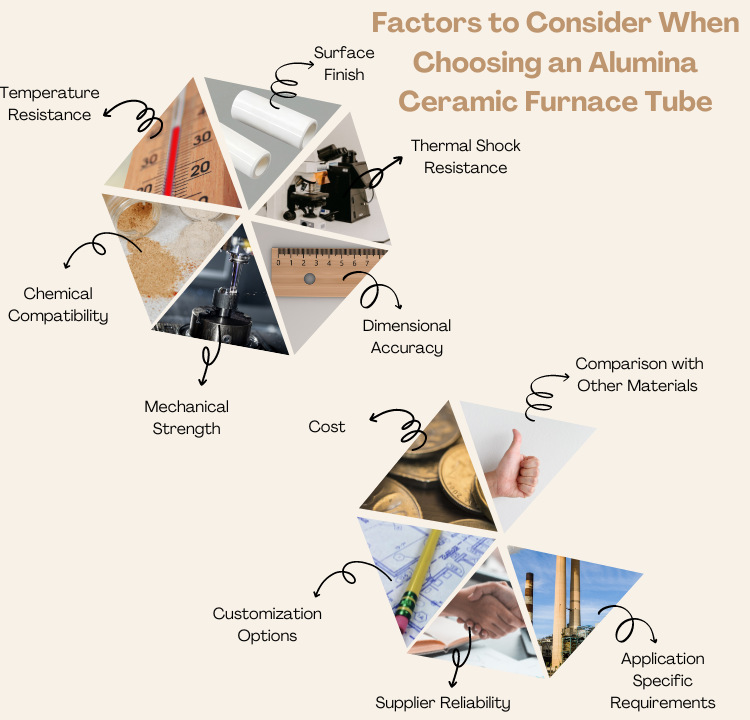

Factors to Consider When Choosing an Alumina Ceramic Furnace Tube

When selecting an alumina ceramic furnace tube, several factors should be taken into consideration to ensure optimal performance and longevity. Let's explore these factors in detail.

1. Temperature Resistance

The temperature resistance of an alumina ceramic furnace tube is a critical factor. It should be able to withstand the maximum operating temperature of your application without compromising its structural integrity. Consider the temperature range you will be working with and choose a tube that has a higher temperature rating than your requirements.

2. Chemical Compatibility

Chemical compatibility is crucial when selecting an alumina ceramic furnace tube. Determine the chemicals present in your application environment and ensure that the tube is resistant to them. Alumina ceramic has excellent resistance to acids, alkalis, and most organic solvents, but it's important to verify its compatibility with the specific chemicals involved.

3. Mechanical Strength

The mechanical strength of the tube is essential to withstand thermal stresses, mechanical loading, and potential impacts. Flexural strength, compressive strength, Young's modulus, and hardness are important parameters to consider. Assess the mechanical requirements of your application and choose a tube that meets or exceeds those requirements.

4. Dimensional Accuracy

The dimensional accuracy of the alumina ceramic furnace tube is crucial for a proper fit within your application setup. Consider factors such as inner diameter, wall thickness, length, surface straightness, roundness, and concentricity. Ensure that the tube dimensions align with your specific requirements to avoid any issues during installation and operation.

5. Thermal Shock Resistance

Thermal shock resistance refers to a material's ability to withstand rapid temperature changes without cracking or breaking. Evaluate the thermal gradient and cycling conditions of your application. Choose a tube that exhibits high thermal shock resistance to prevent thermal stress-related failures.

6. Surface Finish

The surface finish of the alumina ceramic furnace tube impacts factors such as smoothness, cleanliness, and surface roughness (Ra value). A smooth and clean surface minimizes the risk of contamination and enhances heat transfer. Consider the surface finish requirements of your application and choose a tube that meets those criteria.

7. Cost

Cost is a significant consideration when choosing any equipment. Evaluate the initial investment cost of the tube, its expected lifespan, and the cost of potential downtime and maintenance. While it's important to consider your budget, remember that choosing a high-quality tube can result in long-term cost savings.

8. Customization Options

Depending on your application's unique requirements, you may need a custom-sized or shaped alumina ceramic furnace tube. Consider whether the supplier offers customization options to meet your specific needs. Customization can include adjustments to size, shape, and additional features like flanges, grooves, or holes.

CSCERAMIC offer a range of customization options to meet your specific requirements. Whether you need tubes of different lengths, diameters, or configurations, our team of experts is ready to work closely with you to deliver tailored solutions that fit your furnace perfectly.

9. Supplier Reliability

Selecting a reliable supplier is crucial to ensure the quality and performance of the alumina ceramic furnace tube. Consider the supplier's experience, reputation, and customer reviews. A reputable supplier will provide technical support, quality assurance, and timely delivery.

CSCERAMIC takes pride in our commitment to supplier reliability. As a trusted manufacturer, we prioritize delivering consistent and high-quality products to our customers. Our manufacturing processes follow stringent quality control measures, and we have a proven track record of timely product delivery and excellent customer support.

10. Application-Specific Requirements

Different industries have specific requirements for alumina ceramic furnace tubes. Evaluate how well the tube meets the demands of your particular industry. For example, the chemical industry may require resistance to corrosive gases, while semiconductor manufacturing may demand high-purity tubes.

11. Comparison with Other Materials

Compare alumina ceramic furnace tubes with alternative materials to make an informed decision. Quartz tubes offer excellent transparency, while silicon carbide tubes provide superior thermal conductivity. Mullite tubes offer a balance between thermal shock resistance and cost. Assess the pros and cons of each material to determine which one best suits your application.

How to Assess the Temperature Resistance of Alumina Ceramic Furnace Tubes

Assessing the temperature resistance of alumina ceramic furnace tubes is crucial to ensure their suitability for your application. Consider the following parameters:

1. Maximum Operating Temperature

Check the manufacturer's specifications for the maximum operating temperature of the alumina ceramic tube. Ensure that it exceeds the highest temperature reached in your application to avoid structural failure.

2. Thermal Conductivity

Evaluate the thermal conductivity of the tube. Higher thermal conductivity allows for efficient heat transfer, which can be beneficial for applications requiring uniform temperature distribution.

3. Thermal Expansion Coefficient

The thermal expansion coefficient of the tube should be compatible with other components in your setup. Mismatched coefficients can lead to thermal stress and potential failure.

4. Creep Resistance

Creep resistance refers to the ability of the tube to withstand deformation under prolonged exposure to high temperatures. Verify that the alumina ceramic furnace tube exhibits excellent creep resistance for long-term stability.

Evaluating the Chemical Compatibility of Alumina Ceramic Furnace Tubes

Assessing the chemical compatibility of alumina ceramic furnace tubes is essential to ensure their resistance to corrosive substances. Consider the following factors:

1. Chemical Exposure

Identify the chemicals present in your application environment. Alumina ceramic is highly resistant to acids, alkalis, and most organic solvents, but verify its compatibility with the specific chemicals involved.

2. Acid Resistance

Check if the tube has excellent acid resistance, especially if your application involves acidic environments. Alumina ceramic has remarkable resistance to various acids, including sulfuric acid and hydrochloric acid.

3. Alkali Resistance

Evaluate the alkali resistance of the alumina ceramic furnace tube, particularly if your application deals with alkaline substances. Alumina ceramic is known for its resistance to strong alkaline solutions.

4. Oxidation Resistance

Assess the tube's resistance to oxidation, as some applications involve exposure to oxygen or oxidizing atmospheres. Alumina ceramic exhibits good resistance to oxidation, ensuring its stability and longevity.

Understanding the Mechanical Strength of Alumina Ceramic Furnace Tubes

The mechanical strength of alumina ceramic furnace tubes is crucial for their structural integrity and durability. Consider the following parameters:

1. Flexural Strength

Flexural strength determines the tube's ability to resist bending or deformation under external forces. A higher flexural strength ensures better resistance to mechanical stresses.

2. Compressive Strength

Compressive strength refers to the tube's ability to withstand compressive forces. It is essential for applications that involve pressure or heavy loads.

3. Young's Modulus

Young's modulus measures the stiffness of the tube material. Higher Young's modulus indicates greater rigidity and resistance to deformation.

4. Hardness

Hardness determines the tube's resistance to surface abrasion and indentation. A higher hardness value ensures better wear resistance and durability.

Ensuring Dimensional Accuracy for Your Application

Dimensional accuracy is crucial when selecting an alumina ceramic furnace tube to ensure a proper fit within your application setup. Consider the following factors:

1. Inner Diameter and Wall Thickness

Evaluate the required inner diameter and wall thickness of the tube to ensure compatibility with your system. Precise dimensions are necessary for efficient heat transfer and optimal performance.

2. Length and Surface Straightness

Verify the required length of the tube and ensure that it has good surface straightness. Straight and uniform tubes are easier to install and provide reliable performance.

3. Roundness and Concentricity

Check the roundness and concentricity of the tube to ensure it fits well with other components. Precise roundness and concentricity minimize the risk of leaks or inefficiencies in heat transfer.

Assessing the Thermal Shock Resistance of Alumina Ceramic Furnace Tubes

Thermal shock resistance is vital for alumina ceramic furnace tubes exposed to rapid temperature changes. Consider the following factors:

1. Thermal Gradient

Evaluate the thermal gradient that the tube will be subjected to during operation. A high thermal gradient can induce thermal stress, so choose a tube with the appropriate thermal shock resistance to prevent cracking.

2. Thermal Cycling

Consider the frequency and magnitude of thermal cycling in your application. Alumina ceramic tubes with excellent thermal shock resistance can withstand repeated heating and cooling cycles without failure.

3. Crack Propagation Resistance

Assess the tube's ability to resist crack propagation. A tube with good crack propagation resistance will prevent cracks from spreading, ensuring its longevity and reliability.

Importance of Surface Finish for Alumina Ceramic Furnace Tubes

The surface finish of alumina ceramic furnace tubes can impact their performance and usability. Consider the following aspects:

1. Smoothness and Cleanliness

A smooth and clean surface minimizes the risk of contamination and enhances heat transfer efficiency. Ensure that the tube has a smooth surface free from defects, roughness, or contaminants.

2. Ra Value and Surface Roughness

Check the Ra value, which represents the surface roughness. Lower Ra values indicate smoother surfaces, which can reduce friction and improve performance.

Considering the Cost of Alumina Ceramic Furnace Tubes

Cost is an important consideration when choosing an alumina ceramic furnace tube. Consider the following aspects:

1. Initial Investment

Evaluate the upfront cost of the tube. While high-quality alumina ceramic tubes may have a higher initial cost, they often offer better performance, longer lifespan, and cost savings in the long run.

2. Lifespan and Durability

Consider the expected lifespan and durability of the tube. Tubes with longer lifespans may justify a higher upfront cost due to reduced replacement frequency and maintenance.

3. Cost of Downtime and Maintenance

Assess the potential cost of downtime and maintenance associated with the tube. A reliable and durable tube can minimize downtime, maintenance requirements, and associated costs.

Customization Options for Alumina Ceramic Furnace Tubes

Depending on your application's unique requirements, customization options may be necessary. Consider the following aspects:

1. Size and Shape

If standard sizes and shapes do not meet your requirements, ensure that the supplier offers customization options. Custom-sized or shaped tubes can ensure a perfect fit within your application.

2. Additional Features

Consider whether additional features like flanges, grooves, or holes are required for your specific application. Customization options can provide the necessary modifications to meet your needs.

Evaluating Supplier Reliability

Choosing a reliable supplier is crucial to ensure the quality and performance of the alumina ceramic furnace tube. Consider the following factors:

1. Experience and Reputation

Evaluate the supplier's experience in manufacturing alumina ceramic tubes and their reputation in the industry. A supplier with a proven track record is more likely to provide high-quality products.

With years of experience in the industry, CSCERAMIC has built a strong reputation for delivering high-quality furnace-grade alumina ceramic tubes. We have successfully served numerous clients, earning their trust and establishing long-term partnerships. Our proven track record demonstrates our commitment to excellence and customer satisfaction.

2. Quality Assurance

Ensure that the supplier has a robust quality assurance process in place. Look for certifications or standards that validate their commitment to quality.

We understand that quality is of utmost importance to our customers. That's why CSCERAMIC adhere to strict quality control measures throughout the manufacturing process. Our furnace-grade alumina ceramic tubes undergo rigorous testing to ensure they meet the highest industry standards. By maintaining consistent quality, we aim to provide you with reliable and durable products that will meet your specific requirements.

3. Technical Support

Verify if the supplier offers technical support and assistance during the selection and installation process. A reliable supplier should be able to address your queries and provide guidance when needed.

CSCERAMIC believes that excellent technical support is crucial for a seamless customer experience. Our team of knowledgeable and skilled engineers is readily available to assist you with any technical inquiries or challenges you may face. Whether it's providing guidance on product selection, troubleshooting, or customization, we are dedicated to offering comprehensive technical support to help you achieve optimal results.

4. Timely Delivery

Consider the supplier's ability to deliver the alumina ceramic furnace tube within the required timeframe. Timely delivery is essential to avoid delays in your application setup.

CSCERAMIC understands the importance of timely delivery to your operations. Our efficient production processes and streamlined supply chain management enable us to meet your deadlines without compromising on quality. We prioritize punctuality to ensure that your projects progress smoothly, allowing you to stay on schedule and avoid unnecessary disruptions.

Conclusion

Choosing the right alumina ceramic furnace tube for your application requires careful consideration of various factors. Assessing temperature resistance, chemical compatibility, mechanical strength, dimensional accuracy, thermal shock resistance, surface finish, cost, customization options, and supplier reliability is crucial to make an informed decision. By evaluating these aspects and understanding your application's specific requirements, you can select a high-quality tube that ensures optimal performance and longevity.

FAQs

1. Can alumina ceramic furnace tubes be reused after use?

Yes, alumina ceramic furnace tubes can be reused after use, provided they are undamaged and free from contamination. Proper cleaning and inspection are necessary to ensure their suitability for subsequent applications.

2. Are alumina ceramic furnace tubes suitable for high-pressure applications?

Yes, alumina ceramic furnace tubes can be used in high-pressure applications. Their excellent mechanical strength and resistance to thermal and chemical stresses make them suitable for demanding conditions.

3. Can alumina ceramic furnace tubes withstand rapid temperature changes?

Alumina ceramic furnace tubes exhibit good thermal shock resistance, allowing them to withstand rapid temperature changes without cracking or breaking. However, it's essential to choose a tube with suitable thermal shock resistance for specific application requirements.

4. Can alumina ceramic furnace tubes be custom-designed for specific applications?

Yes, many suppliers offer customization options for alumina ceramic furnace tubes. Customization can include adjustments to size, shape, and additional features to meet the specific needs of your application.

5. How long do alumina ceramic furnace tubes typically last?

The lifespan of alumina ceramic furnace tubes can vary depending on factors such as application conditions, operating temperatures, and maintenance practices. With proper care and usage, these tubes can last several years, providing reliable performance.

Thank you for reading. We invite you to visit CSCERAMIC for more information if you would like to learn more about industrial ceramic material and the advanced range of ceramic products we offer.

info@csceramic.com

info@csceramic.com

+86 18273288522

+86 18273288522