Comparison of Different Grades of Alumina Ceramic Tubes and Their Price-Performance Ratio

Are you in search of high-quality alumina ceramic tubes for your industrial applications? Choosing the right grade of alumina ceramic is crucial to ensure optimal performance and durability. With various grades available in the market, it's essential to understand their characteristics and the price-performance ratio they offer. In this article, we will compare different grades of alumina ceramic tubes and explore their unique features, benefits, and cost-effectiveness.

Introduction

Alumina ceramic tubes are widely used in industries such as aerospace, automotive, chemical, electronics, and more. These tubes offer exceptional mechanical strength, resistance to high temperatures, corrosion resistance, electrical insulation properties, and excellent wear resistance. However, different grades of alumina ceramic tubes exhibit variations in these properties, making it important to select the right grade based on your specific requirements.

Understanding Alumina Ceramic Tubes

Alumina ceramic tubes are primarily composed of aluminum oxide (Al2O3) and other additives. The percentage of aluminum oxide and the type of additives determine the properties and characteristics of the ceramic tubes. Manufacturers produce various grades of alumina ceramic tubes by altering the composition and processing techniques.

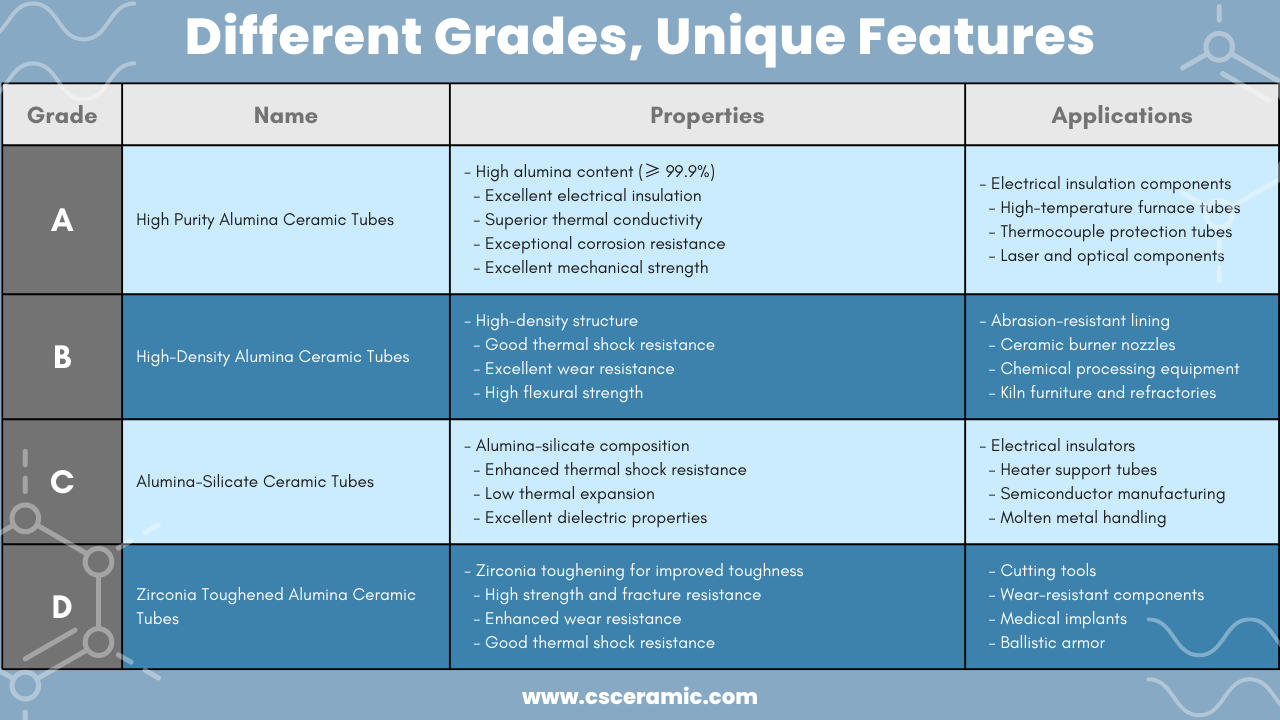

Different Grades, Unique Features

Now, let's delve into the different grades of alumina ceramic tubes and their unique features.

Grade A: High Purity Alumina Ceramic Tubes

- Properties:

- High alumina content (≥ 99.9%)

- Excellent electrical insulation

- Superior thermal conductivity

- Exceptional corrosion resistance

- Excellent mechanical strength

- Applications:

- Electrical insulation components

- High-temperature furnace tubes

- Thermocouple protection tubes

- Laser and optical components

Grade B: High-Density Alumina Ceramic Tubes

- Properties:

- High-density structure

- Good thermal shock resistance

- Excellent wear resistance

- High flexural strength

- Applications:

- Abrasion-resistant lining

- Ceramic burner nozzles

- Chemical processing equipment

- Kiln furniture and refractories

Grade C: Alumina-Silicate Ceramic Tubes

- Properties:

- Alumina-silicate composition

- Enhanced thermal shock resistance

- Low thermal expansion

- Excellent dielectric properties

- Applications:

- Electrical insulators

- Heater support tubes

- Semiconductor manufacturing

- Molten metal handling

Grade D: Zirconia Toughened Alumina Ceramic Tubes

- Properties:

- Zirconia toughening for improved toughness

- High strength and fracture resistance

- Enhanced wear resistance

- Good thermal shock resistance

- Applications:

- Cutting tools

- Wear-resistant components

- Medical implants

- Ballistic armor

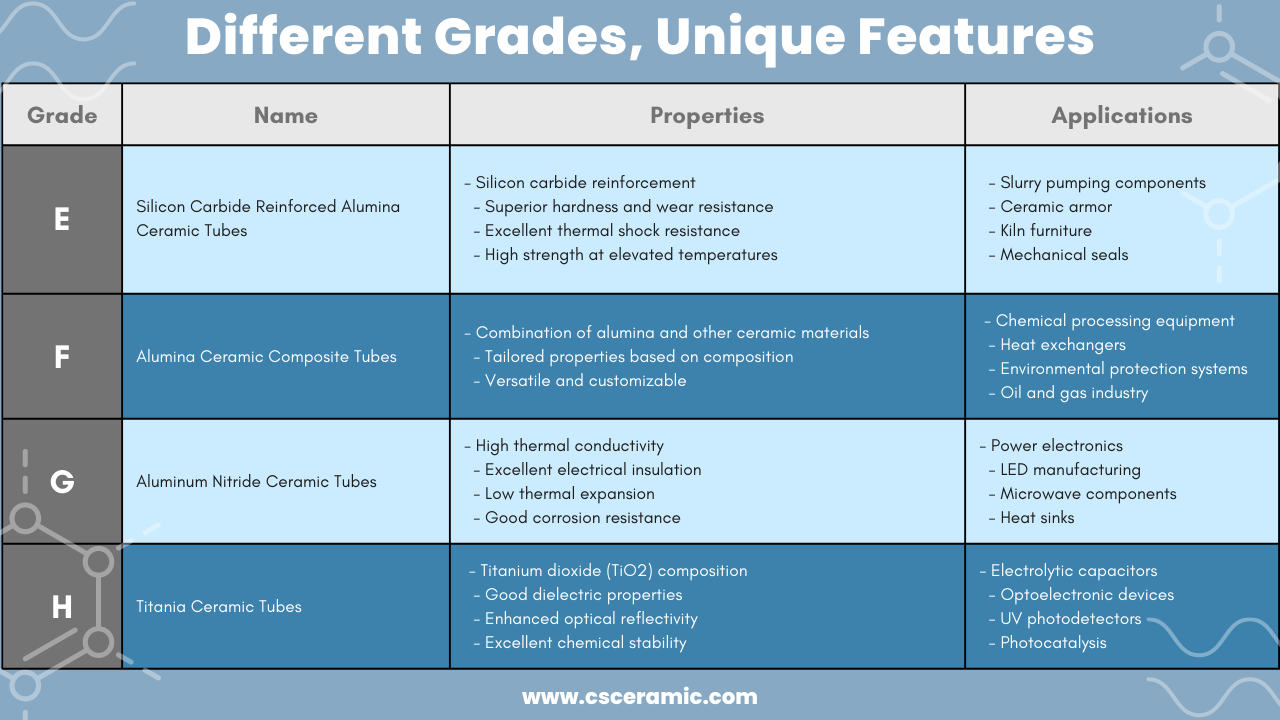

Grade E: Silicon Carbide Reinforced Alumina Ceramic Tubes

- Properties:

- Silicon carbide reinforcement

- Superior hardness and wear resistance

- Excellent thermal shock resistance

- High strength at elevated temperatures

- Applications:

- Slurry pumping components

- Ceramic armor

- Kiln furniture

- Mechanical seals

Grade F: Alumina Ceramic Composite Tubes

- Properties:

- Combination of alumina and other ceramic materials

- Tailored properties based on composition

- Versatile and customizable

- Applications:

- Chemical processing equipment

- Heat exchangers

- Environmental protection systems

- Oil and gas industry

Grade G: Aluminum Nitride Ceramic Tubes

- Properties:

- High thermal conductivity

- Excellent electrical insulation

- Low thermal expansion

- Good corrosion resistance

- Applications:

- Power electronics

- LED manufacturing

- Microwave components

- Heat sinks

Grade H: Titania Ceramic Tubes

- Properties:

- Titanium dioxide (TiO2) composition

- Good dielectric properties

- Enhanced optical reflectivity

- Excellent chemical stability

- Applications:

- Electrolytic capacitors

- Optoelectronic devices

- UV photodetectors

- Photocatalysis

Price-Performance Ratio Evaluation

When evaluating the price-performance ratio of different grades of alumina ceramic tubes, it's crucial to consider your specific application requirements. Each grade offers unique properties and performance characteristics, which directly impact their cost. Higher purity and specialized compositions generally lead to higher prices. However, the enhanced performance and longevity of premium grades often justify the investment in certain applications.

Conclusion

Selecting the right grade of alumina ceramic tubes is vital for achieving optimal performance, durability, and cost-effectiveness in industrial applications. By understanding the unique properties of different grades, you can make an informed decision that aligns with your specific requirements. Whether you prioritize electrical insulation, thermal conductivity, wear resistance, or other properties, there is a suitable alumina ceramic grade available to meet your needs.

FAQs

1. What are the primary factors to consider when choosing an alumina ceramic tube grade?

When selecting a grade, consider factors such as electrical insulation, thermal conductivity, thermal shock resistance, wear resistance, and corrosion resistance based on your application requirements.

2. Are higher-priced grades always better in terms of performance?

Higher-priced grades often offer superior performance due to higher purity and specialized compositions. However, the suitability depends on your specific application needs.

3. Which grade is recommended for high-temperature applications?

Grade A (High Purity Alumina Ceramic Tubes) and Grade D (Zirconia Toughened Alumina Ceramic Tubes) are commonly used for high-temperature applications due to their exceptional thermal stability.

4. Can alumina ceramic tubes be customized for specific applications?

Yes, alumina ceramic tubes can be customized by adjusting the composition, additives, and processing techniques to meet the specific requirements of diverse applications.

Thank you for reading. We invite you to visit CSCERAMIC for more information if you would like to learn more about industrial ceramic material and the advanced range of ceramic products we offer.

info@csceramic.com

info@csceramic.com

+86 18273288522

+86 18273288522