What Are the Different Sizes and Shapes of Alumina Ceramic Crucibles Available?

Are you in need of a reliable and durable container for your high-temperature experiments or processes? Alumina ceramic crucibles might be the perfect solution for you. These crucibles offer excellent thermal resistance, chemical inertness, and stability at extreme temperatures. They are widely used in various industries, including metallurgy, chemistry, materials science, and more. In this article, we will explore the different sizes and shapes of alumina ceramic crucibles available, helping you choose the right one for your specific needs.

Table of Contents

|

1. Introduction |

2. Alumina Ceramic Crucibles: An Overview |

|

2.3. Round Crucibles |

2.4. Square Crucibles |

|

2.5. Cylindrical Crucibles |

2.6. Conical Crucibles |

|

2.7. Customized Shapes and Sizes |

3. Crucible Size Considerations |

|

4. Crucible Lid Options |

5. Crucible Accessories |

|

6. Crucible Care and Maintenance |

7. Advantages of Alumina Ceramic Crucibles |

|

8. Applications of Alumina Ceramic Crucibles |

9. Conclusion |

| 10. Frequently Asked Questions (FAQs) | |

Introduction

When conducting experiments or processes involving high temperatures, it is essential to have a container that can withstand such extreme conditions. Alumina ceramic crucibles are specifically designed to meet these requirements. They are made from high-purity alumina, which possesses exceptional thermal properties and resistance to thermal shock. Additionally, alumina is chemically inert, making it suitable for a wide range of applications.

Alumina Ceramic Crucibles: An Overview

Alumina ceramic crucibles are available in various sizes and shapes to accommodate different experimental needs. Let's explore some of the commonly used shapes:

Round Crucibles

Round crucibles are the most traditional and widely used shape. They have a cylindrical body with a rounded bottom, offering excellent heat distribution and efficient melting capabilities. Round crucibles are ideal for general-purpose applications, including melting, calcination, and sample preparation.

Square Crucibles

Square crucibles feature a square or rectangular shape, providing a larger surface area for sample containment. They are commonly used for applications that require more space or for experiments involving powder mixing or grinding.

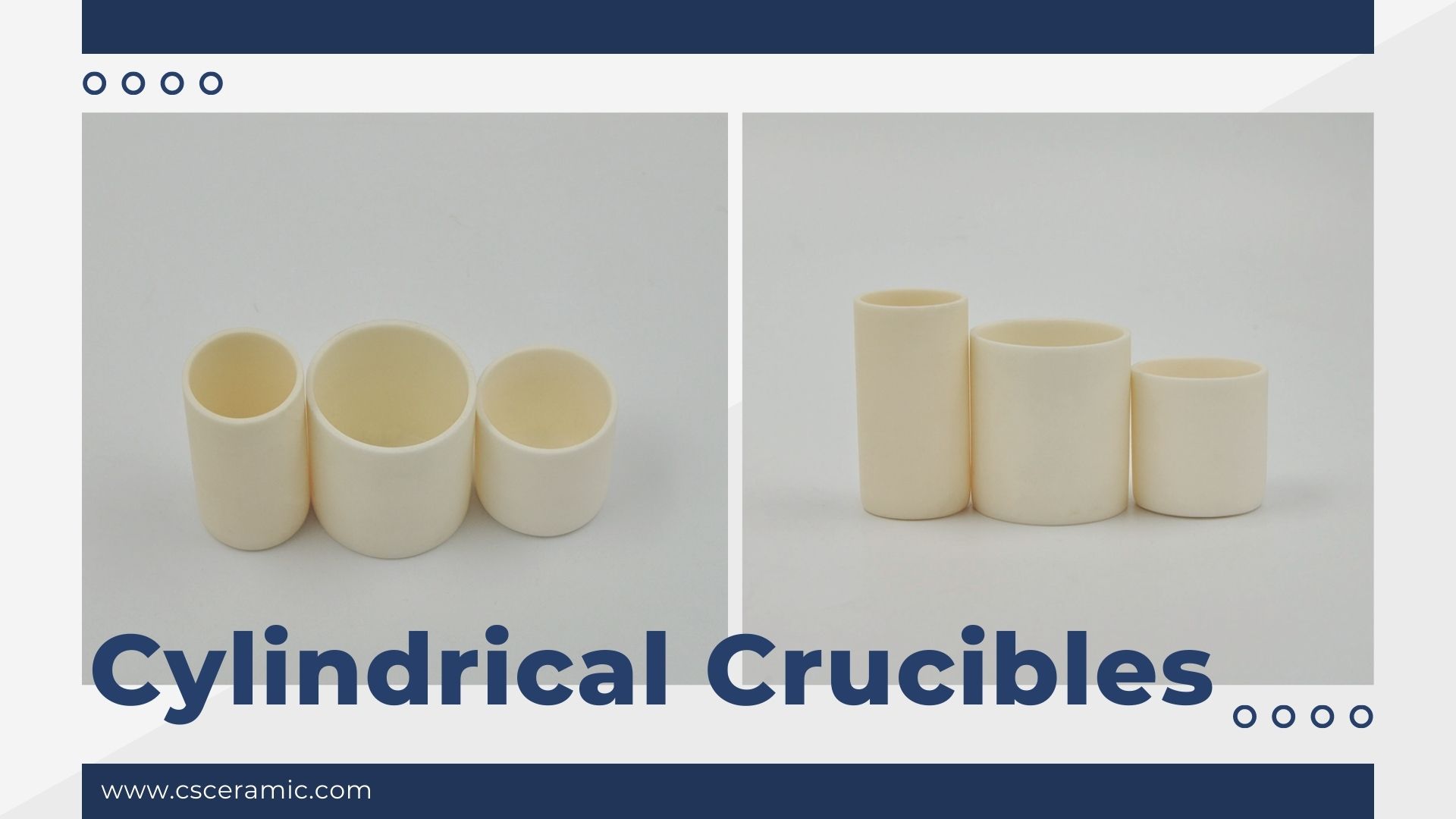

Cylindrical Crucibles

Cylindrical crucibles resemble round crucibles but have straighter sides instead of a curved bottom. This shape allows for easier pouring and transferring of molten materials. Cylindrical crucibles are often used in applications such as metal casting, alloying, and other processes that involve precise pouring techniques.

Conical Crucibles

Conical crucibles, as the name suggests, have a conical shape with a tapered bottom. This design facilitates easy pouring and controlled flow of molten materials. Conical crucibles are commonly utilized in applications that require precise pouring or when working with materials that solidify rapidly.

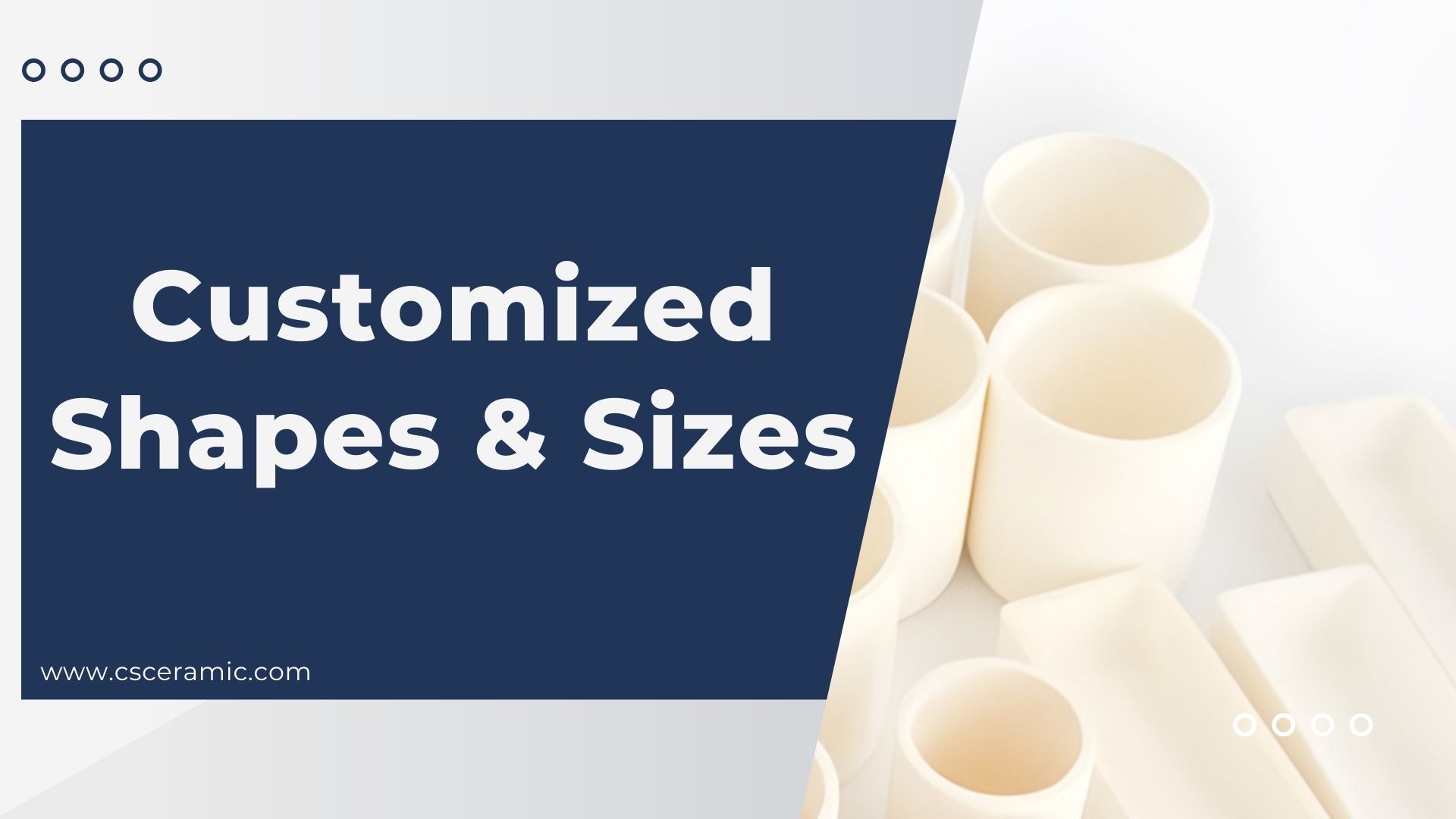

Customized Shapes and Sizes

In addition to the standard shapes mentioned above, manufacturers can create alumina ceramic crucibles in customized shapes and sizes to meet specific requirements. These custom crucibles can be tailored to fit unique experimental setups or specialized applications, providing flexibility and versatility.

Crucible Size Considerations

When selecting an alumina ceramic crucible, it is crucial to consider the size that best suits your needs. Factors such as sample volume, heating method, and available laboratory space should be taken into account. Crucibles are available in a wide range of sizes, from small micro crucibles for microscale experiments to large crucibles for industrial-scale processes.

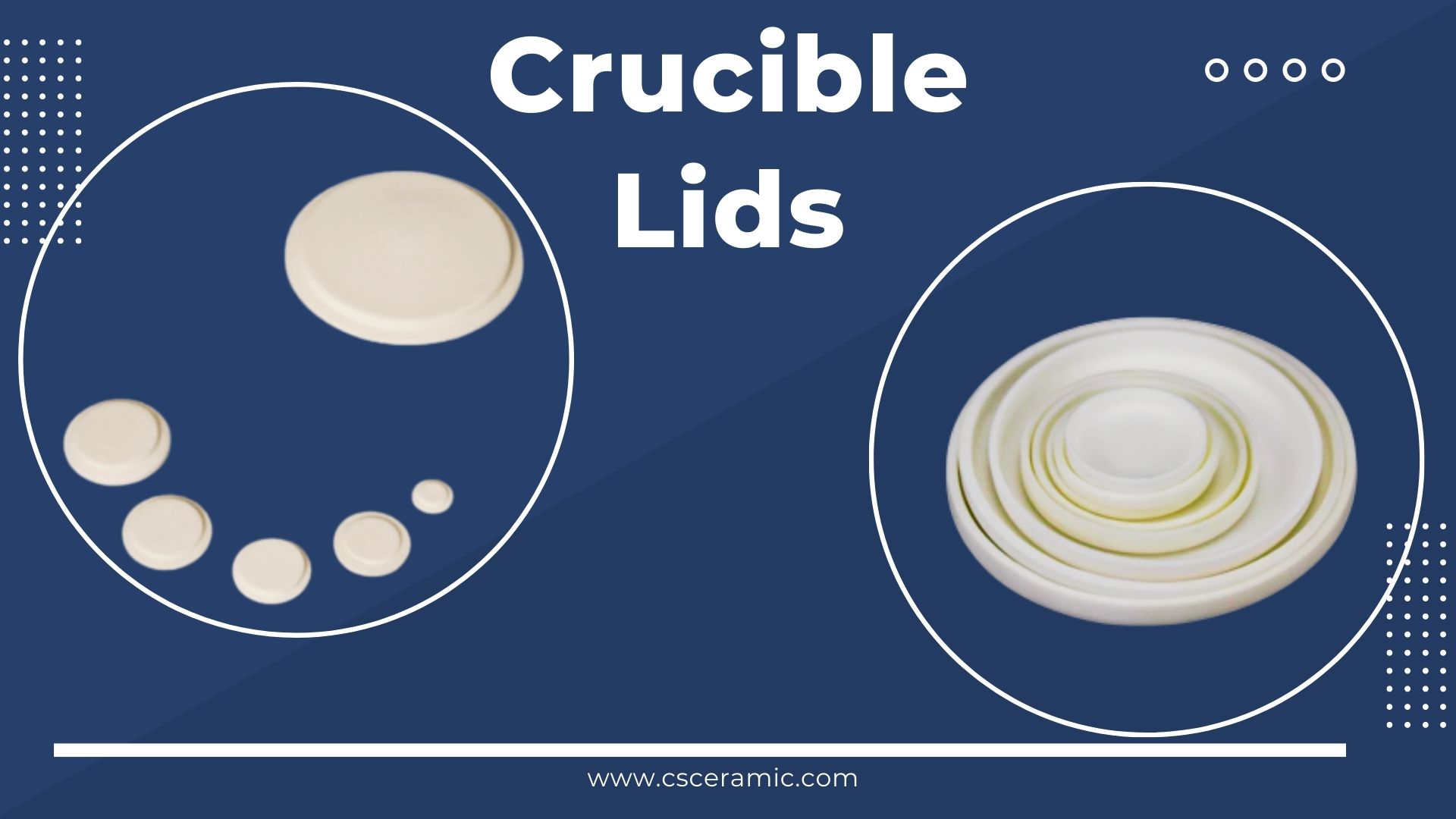

Crucible Lid Options

To further enhance the performance of alumina ceramic crucibles, manufacturers offer various lid options. Crucible lids help retain heat, prevent contamination, and improve temperature uniformity within the crucible. Common lid types include flat lids, domed lids, and lids with holes for introducing gases or inserting thermocouples.

Crucible Accessories

Several accessories can complement the use of alumina ceramic crucibles. These include tongs or holders for safe handling of hot crucibles, crucible liners for easier cleaning, and stirring rods for homogeneous mixing of materials. Using appropriate accessories can improve safety and enhance experimental efficiency.

Crucible Care and Maintenance

To ensure the longevity of your alumina ceramic crucibles, proper care and maintenance are essential. After each use, it is recommended to clean the crucible thoroughly, removing any residue or contaminants. Avoid sudden temperature changes to prevent thermal shock and handle the crucible with care to avoid accidental damage.

Advantages of Alumina Ceramic Crucibles

Alumina ceramic crucibles offer numerous advantages over other materials:

- Exceptional thermal resistance

- High chemical inertness

- Excellent stability at high temperatures

- Low thermal expansion

- Good electrical insulation properties

Applications of Alumina Ceramic Crucibles

Alumina ceramic crucibles find extensive applications across various industries and laboratory settings due to their exceptional properties. Let's explore some specific applications where these crucibles excel:

Melting and Casting of Metals and Alloys

Alumina ceramic crucibles are widely used for melting and casting metals and alloys. Their high thermal resistance allows them to withstand the extreme temperatures required for metal melting processes. Whether you're working with precious metals or industrial alloys, alumina crucibles provide a reliable and durable container for the melting and casting procedures.

Calcination and Sintering of Ceramics

In the field of ceramics, alumina ceramic crucibles are essential for calcination and sintering processes. Calcination involves heating ceramic materials to high temperatures to remove organic impurities or moisture. Alumina crucibles provide a stable and inert environment for this process, ensuring consistent and controlled heating. Similarly, during the sintering process, where ceramic particles are fused together, alumina crucibles offer excellent thermal properties and prevent contamination.

Heat Treatment and Annealing Processes

Alumina ceramic crucibles are commonly used for heat treatment and annealing processes. Heat treatment involves subjecting materials to controlled heating and cooling cycles to alter their properties. Annealing, on the other hand, involves heating materials to relieve internal stresses and enhance their ductility. Alumina crucibles facilitate precise temperature control and provide a chemically inert environment necessary for successful heat treatment and annealing.

Analysis and Sample Preparation in Laboratories

Alumina ceramic crucibles play a crucial role in various laboratory analyses and sample preparation procedures. They are used for weighing, mixing, and heating samples in analytical chemistry, materials science, and other scientific disciplines. These crucibles are compatible with a wide range of chemicals and can withstand the high temperatures required for sample preparation techniques like digestion, ashing, or fusion.

Crucible Furnaces and Kilns

Alumina ceramic crucibles are integral components of crucible furnaces and kilns. These furnaces are used in industries such as metallurgy, glassmaking, and ceramics manufacturing. Alumina crucibles provide a reliable and durable container for heating materials to extremely high temperatures, allowing for efficient and controlled processing.

Chemical Synthesis and Reactions

Alumina ceramic crucibles are also utilized in chemical synthesis and reactions. Their excellent chemical inertness makes them suitable for handling corrosive or reactive chemicals. Whether it's conducting organic syntheses, performing acid-base reactions, or carrying out catalyst testing, alumina crucibles offer a stable and resistant environment for various chemical processes.

By leveraging the unique properties of alumina ceramic crucibles, researchers, scientists, and industrial professionals can confidently perform a wide range of applications. These crucibles contribute to the success and reliability of high-temperature experiments, sample preparation, and material processing in numerous fields.

Conclusion

Alumina ceramic crucibles are an indispensable tool in high-temperature experiments and processes. With their diverse shapes and sizes, these crucibles can accommodate a wide range of applications. Whether you need a round, square, cylindrical, conical, or custom-shaped crucible, there is an option available to suit your specific needs. By choosing alumina ceramic crucibles, you ensure durability, thermal resistance, and chemical inertness for your experimental setup.

Frequently Asked Questions (FAQs)

Q1. Can alumina ceramic crucibles be reused?

Yes, alumina ceramic crucibles can be reused multiple times. It is important to clean them thoroughly after each use to remove any residual materials.

Q2. Are alumina ceramic crucibles suitable for high-temperature applications?

Yes, alumina ceramic crucibles are specifically designed to withstand high temperatures. They exhibit excellent thermal resistance and stability, making them ideal for high-temperature processes.

Q3. Can I use alumina ceramic crucibles in a microwave?

No, alumina ceramic crucibles are not suitable for use in a microwave. They are primarily designed for use in conventional furnaces or kilns.

Q4. How do I choose the right size of crucible for my experiment?

When selecting a crucible size, consider the sample volume, available laboratory space, and heating method. It is advisable to consult the manufacturer's guidelines or seek expert advice if unsure.

Q5. Can I use alumina ceramic crucibles with corrosive chemicals?

Alumina ceramic crucibles are highly resistant to chemical attack and are suitable for use with most corrosive chemicals. However, it is always recommended to check the compatibility with specific chemicals before use.

Thank you for reading. We invite you to visit CSCERAMIC for more information if you would like to learn more about industrial ceramic material and the advanced range of ceramic products we offer.

info@csceramic.com

info@csceramic.com

+86 18273288522

+86 18273288522