What Safety Precautions Should You Follow When Using Alumina Ceramic Crucibles in the Lab?

In the laboratory, safety should always be a top priority. When working with alumina ceramic crucibles, it is essential to follow certain safety precautions to ensure a safe and productive work environment. Alumina ceramic crucibles are commonly used in various laboratory applications, including sample preparation, heating, and chemical reactions. This article will guide you through the safety precautions that should be when using alumina ceramic crucibles in the lab.

Introduction

In the laboratory, using the right equipment and following safety protocols is crucial to prevent accidents and ensure accurate results. Alumina ceramic crucibles are popular due to their excellent thermal properties, chemical resistance, and durability. However, it is essential to understand the necessary safety precautions associated with their use to minimize risks.

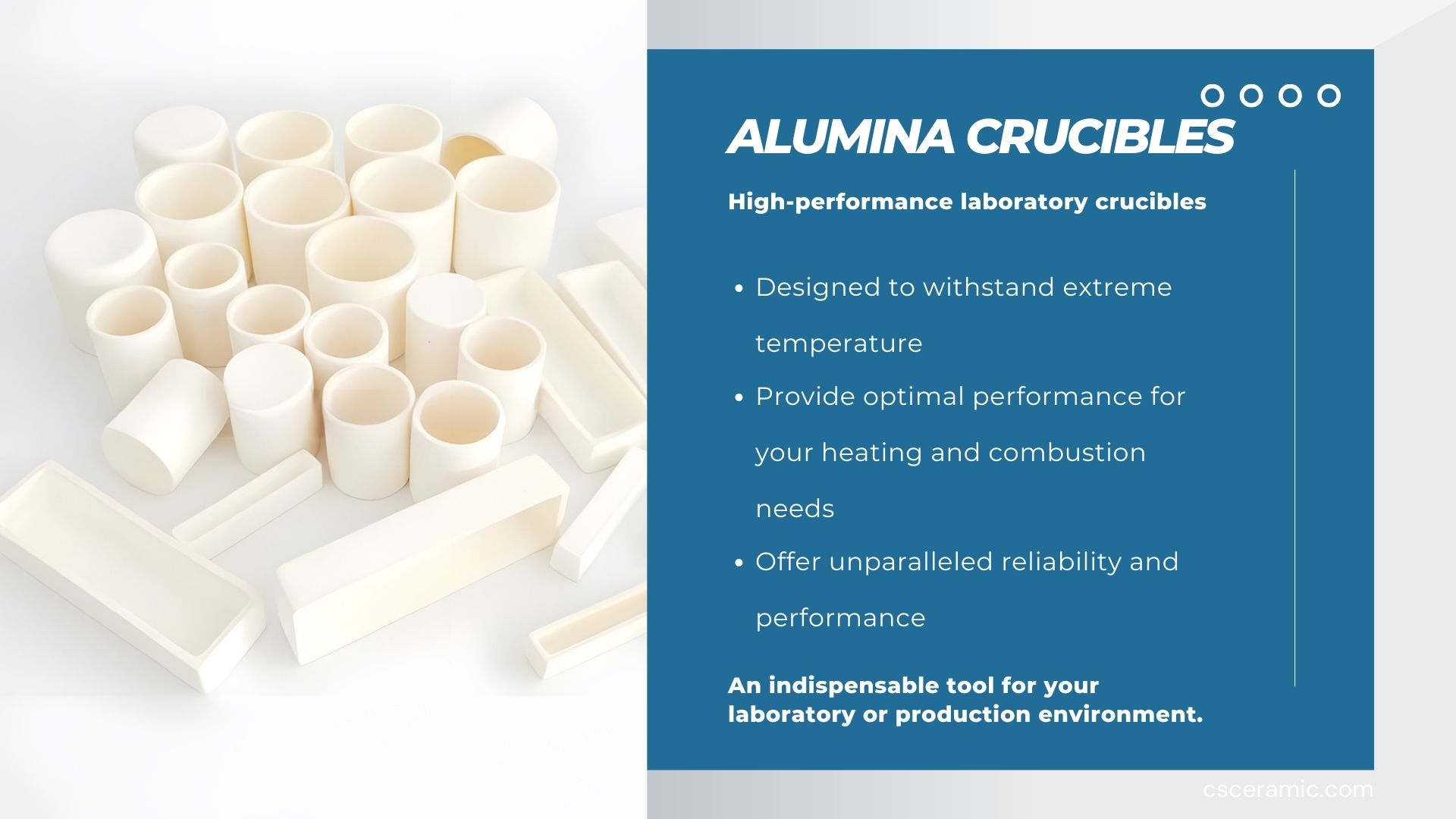

Understanding Alumina Ceramic Crucibles

Alumina ceramic crucibles are containers made of high-purity aluminum oxide, a type of ceramic material known for its exceptional resistance to high temperatures and corrosive substances. They are often used in high-temperature applications, such as melting, sintering, and heat treatment of samples.

Preparing the Workstation

1. Ensure a clean and organized workspace to minimize the risk of accidents.

2. Remove any flammable materials or chemicals from the vicinity of the workstation.

3. Have a fire extinguisher and a first aid kit readily available.

Handling Alumina Ceramic Crucibles

1. Before use, inspect the crucible for any cracks, chips, or other visible damage. Do not use a damaged crucible, as it may lead to breakage during heating or chemical reactions.

2. Always handle alumina ceramic crucibles with clean, dry hands or appropriate gloves to avoid contamination.

3. Use suitable tongs or crucible holders to handle hot crucibles.

4. Avoid applying excessive force or impact on the crucible, as it may cause breakage.

Heating and Cooling Procedures

1. Gradually heat the alumina ceramic crucible to prevent thermal shock. Sudden temperature changes can lead to cracking or shattering.

2. Use a compatible heating method and ensure that the crucible is placed securely in the heating apparatus.

3. Allow the crucible to cool down naturally after heating. Do not quench it in water or any other cooling medium, as it may cause thermal stress.

Avoiding Chemical Reactions

1. Before adding any substances to the crucible, ensure compatibility with alumina ceramic.

2. Avoid mixing incompatible chemicals that may react violently or produce toxic fumes.

3. Follow established protocols and safety data sheets (SDS) for handling and transferring chemicals into the crucible.

Cleaning and Maintenance

1. Allow the crucible to cool down completely before cleaning.

2. Clean the crucible with mild detergent and water, using non-abrasive tools.

3. Avoid using metal scrubbers or abrasive materials that can scratch the crucible's surface.

4. Rinse the crucible thoroughly to remove any detergent residue before reuse.

Proper Storage

1. Store alumina ceramic crucibles in a designated area away from direct sunlight, extreme temperatures, and moisture.

2. Place them on a stable surface, away from edges or areas where they may accidentally fall.

Personal Protective Equipment (PPE)

1. Always wear appropriate PPE, including heat-resistant gloves, safety goggles, and a lab coat, when handling alumina ceramic crucibles.

2. Consider using a face shield for additional protection, especially during high-temperature applications.

Emergency Response

1. Familiarize yourself with the location and operation of emergency equipment, such as eyewash stations and safety showers.

2. Develop an emergency response plan and ensure all laboratory personnel are aware of the procedures.

Disposal of Alumina Ceramic Crucibles

1. Check local regulations and guidelines for the proper disposal of alumina ceramic crucibles.

2. If the crucible is contaminated with hazardous substances, follow the appropriate disposal protocols to prevent environmental contamination.

Common Mistakes to Avoid

1. Using damaged or cracked crucibles.

2. Applying excessive force or impact on the crucible.

3. Rapidly cooling the crucible after heating.

4. Mixing incompatible chemicals without proper precautions.

Conclusion

Using alumina ceramic crucibles in the laboratory offers many advantages, but it is crucial to prioritize safety. By following the outlined safety precautions, you can minimize the risk of accidents, ensure accurate experimental results, and maintain a safe working environment.

FAQs

Q1: Can alumina ceramic crucibles be used with corrosive substances?

Yes, alumina ceramic crucibles are highly resistant to corrosive substances and can be safely used with a wide range of chemicals.

Q2: Can I reuse alumina ceramic crucibles?

Yes, alumina ceramic crucibles can be reused after proper cleaning and inspection for any damage or contamination.

Q3: Are alumina ceramic crucibles suitable for high-temperature applications?

Absolutely. Alumina ceramic crucibles are specifically designed for high-temperature applications and can withstand extreme heat without significant deformation.

Q4: What should I do if an alumina ceramic crucible breaks during use?

In case of a broken crucible, exercise caution and dispose of the broken pieces properly to prevent injury. Clean the area thoroughly to remove any remaining fragments.

Q5: Are there any special storage requirements for alumina ceramic crucibles?

Store alumina ceramic crucibles in a cool, dry place, away from direct sunlight and moisture. Ensure they are placed on a stable surface to avoid accidental falls.

Thank you for reading. We invite you to visit CSCERAMIC for more information if you would like to learn more about industrial ceramic material and the advanced range of ceramic products we offer.

info@csceramic.com

info@csceramic.com

+86 18273288522

+86 18273288522