Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read Moreitem no. :

CS-FT-9001Material : Alumina ceramic

Aluminum oxide membrane tube can be reused, easy to clean, so operating cost can be reduced.

Applications of Alumina Filtration Tube

Alumina membrane filter wall abounds with microholes, the raw material liquid flows in the membrane tube or outside the membrane, small molecular substances (or liquid) through the membrane, macromolecular substances (or solid) are trapped by the membrane, in food and beverage manufacturing, biomedicine, fine chemical industry and many other fields have a very important application, can be used in the process of separation, clarification, purification, concentration, sterilization, desalt, etc.

1. Food and beverage industry

Alumina membrane filter tube can be used in milk filtration, juice concentration, natural plant extract, wine/tea beverage production, etc.

2. Chemical industry

Alumina membrane tubular filter is widely used for solid-liquid separation, gas-solid separation, and organics separation and purification, such as benzene, phenol, alcohol, various pigments.

3. Environmental protection

It is used for purifying oily wastewater, textile wastewater, urban sewage and paper-making wastewater, as well as high temperature waste gas purification.

4. Biomedical field

It can be used to seperate particles, bacteria and macromolecular impurities in the medicine, and decolor medicine, or refine and concentrate medicine liquid, extract the active ingredients, effective monomers, etc.

Size Chart of Alumina Tubular Filtration Tube

| Alumina Tubular Filtration Tube | ||||||||

| Item No. | Numbers of channels | External Diameter (mm) | End Diaemter (mm) | Channels Diameter (mm) | Cross-Sectional Area of Channel (cm2) | Membrane Areas(M2) for 1-meter-long tube | Membrane Areas(M2) for 1.2-meter-long tube | |

| CS-FT-9001 | 7 | 25.5 | 25 | 6 | 1.98 | 0.14 | 0.158 | |

| CS-FT-9002 | 19 | 25.5 | 25 | 3.5 | 1.62 | 0.2 | 0.246 | |

| CS-FT-9003 | 19 | 30.5 | 30 | 3.8 | 2.55 | 0.227 | 0.272 | |

| CS-FT-9004 | 19 | 41 | 40 | 6 | 5.37 | 0.36 | 0.43 | |

| CS-FT-9005 | 37 | 41 | 40 | 3.8 | 4.19 | 0.442 | 0.53 | |

Usage Instructions

1. Prepare

Before using the alumina membrane tube, it needs to be cleaned and disinfected. Generally use hot water or detergent to clean, and use steam for disinfection. If there is damage or defect, it should be replaced or repaired.

2. Use method

(1) Selection: choose appropriate alumina membrane tube specification, to get the best filtration accuracy;

(2) Installation: when install alumina membrane tube in the corresponding filter equipment, operation shall be carried out in strict accordance with the instructions;

(3) Starting and closing of the membrane tube: Before starting the membrane tube, make sure it is well connected to pipeline and water pump in the equipment, and be sure to turn on the water pump first, and then start the filter membrane; After the membrane is closed, it's better to clean it to get the best service life.

3. Maintenance precautions

(1) Check the membrane tube regularly, and deal with problems such as blockage or damage.

(2) Regularly clean and disinfect the filter membrane to ensure its normal operation.

(3) Record maintenance and replancement of the membrane tube, to decide reasonable maintenance cycle and service life.

(4) Replace the membrane tube or filter membrane accessories regularly to ensure its filtration effect and stability.

We are committed to delivering high-quality alumina ceramic tubes tailored to your exact specifications. Our dedicated team ensures meticulous adherence to your instructions, striving to exceed customer expectations. Additionally, we offer the flexibility of custom sizes to accommodate your unique requirements.

Send Requirements for Custom Design

Kindly furnish the necessary customized information listed below for further assistance:

1. Application scenario

2. The liquid and impurity composition to be filtered, impurity particle size

3. Designed fluid flow rate

4. Membrane tube size and other requirements

Valuable Information

Material: high purity alumina

Pore size: 1-500μm

Maximum operating pressure: 1MPa

Hardness: Mohs hardness 9; Vickers hardness HV1500-1700

Elastic modulus :380GPa

Flexural strength :300Mpa

Compressive strength: 2000MPa

Maximum operating temperature: 1600℃

Linear expansion coefficient: 7.2~8.6X10-6/℃

In compliance with EU ROHS environmental standards

Square Alumina Rod Alumina Ceramic Rods Length 1-2500mm

Square Alumina Rod Alumina Ceramic Rods Length 1-2500mm

Square alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Circle Alumina Rod Ceramic Rods Length 1-2500mm

Circle Alumina Rod Ceramic Rods Length 1-2500mm

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Triangle Alumina Rod Alumina Ceramic Rods

Triangle Alumina Rod Alumina Ceramic Rods

Triangle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Alumina Ceramic Pipes Thermocouple Insulator Ceramic Protection Tube(Closed one End) 1-2500mm

Alumina Ceramic Pipes Thermocouple Insulator Ceramic Protection Tube(Closed one End) 1-2500mm

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Thermocouple protection alumina tubes is mainly used to divide the different electrode of themometric element, they are lightweight and cost-effective, making them a great choice for cost-conscious applications.

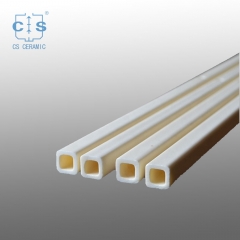

Square Alumina Ceramic Tubes One hole 1-2000mm

Square Alumina Ceramic Tubes One hole 1-2000mm

Square alumina tubes have high corrosion resistance, excellent thermal shock resistance, high thermal insulation. A variety of specifications available. OEM/ODM is acceptable.

Alumina Ceramic Tubes/Pipes Both Open Single Bore Tubes Length 1mm-2500mm

Alumina Ceramic Tubes/Pipes Both Open Single Bore Tubes Length 1mm-2500mm

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

OEM Alumina Rod Ceramic Rods

OEM Alumina Rod Ceramic Rods

Alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.All sizes can be customized and can be made into various complex shapes with high dimensional accuracy.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522