Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

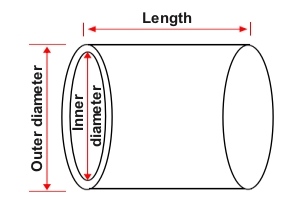

item no. :

CS-AT-001Material : Alumina ceramic

Length : 1mm--2500mm

Shape : Both open

Aluminum oxide ceramic tube, also known as alumina ceramic tube, is cylindrical structures made from aluminum oxide (Al2O3) material.

| 1. |

Aluminum oxide tubes are made of high-grade alumina, offering superior heat and chemical resistance. |

| 2. |

The design of the alumina tubes allows for maximum air flow and efficient heat transfer. |

| 3. |

They are lightweight and easy to install, making them a great choice for a wide variety of applications. |

| 4. |

Alumina tubes are designed for durability and long-term use, ensuring you get the most out of your investment. |

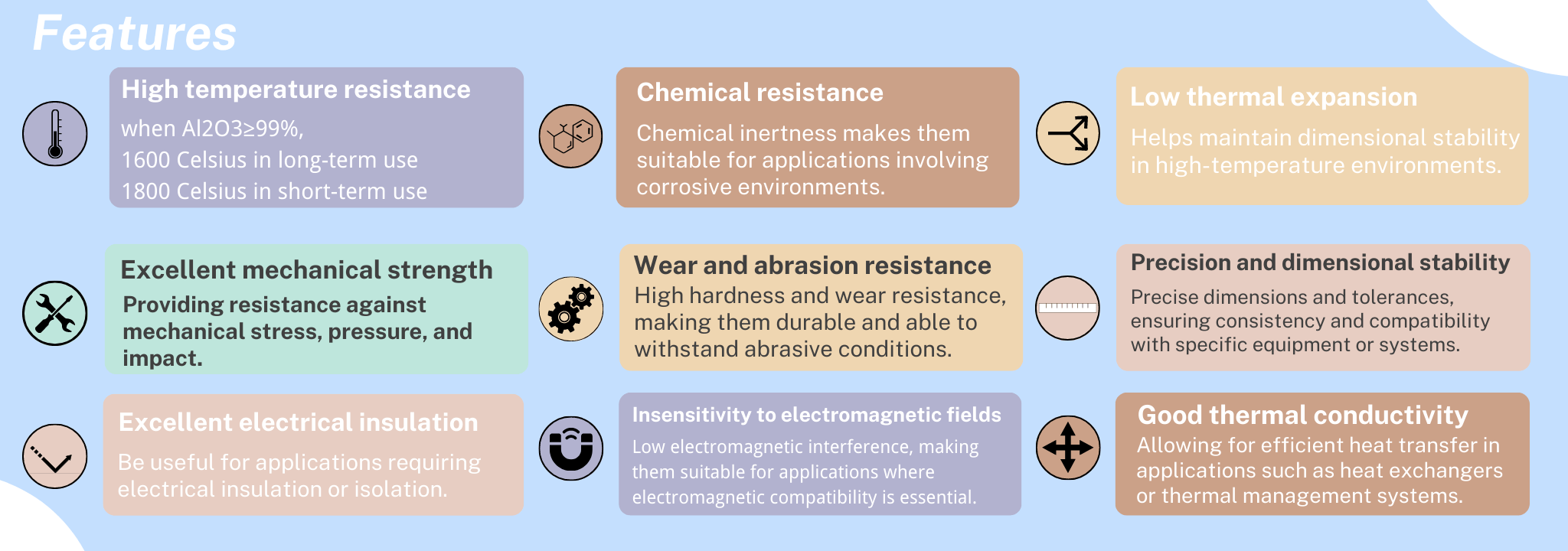

Aluminum oxide ceramic tubes can withstand extreme temperatures(1600℃), making them suitable for applications involving high-temperature environments and thermal processes.

These ceramic tubes exhibit a high tensile strength and modulus of elasticity (up to 200 GPa), providing resistance against mechanical stress, pressure, and impact.

Alumina ceramic tubes possess excellent electrical insulation properties, making them useful for applications requiring electrical insulation or isolation.

They have exceptional resistance to various chemicals, acids, and bases. This chemical inertness makes them suitable for applications involving corrosive environments.

Aluminum oxide ceramic tubes exhibit high hardness and wear resistance, making them durable and able to withstand abrasive conditions.

These tubes have a low coefficient of thermal expansion (10.3 x 10-6/K), meaning they expand or contract minimally with changes in temperature. This property helps maintain dimensional stability in high-temperature environments.

Alumina ceramic tubes have relatively high thermal conductivity (approximately 25 W/mK), allowing for efficient heat transfer in applications such as heat exchangers or thermal management systems.

Aluminum oxide ceramic tubes can be manufactured with precise dimensions and tolerances, ensuring consistency and compatibility with specific equipment or systems.

Alumina ceramic tubes exhibit low electromagnetic interference, making them suitable for applications where electromagnetic compatibility is essential.

| Alumina Tube (both sides open) | ||||||||

| Item NO. |

Outer diameter*

Inner diameter

(mm)

|

Length & Purity | Item NO. |

Outer diameter*

Inner diameter

(mm)

|

Length & Purity | Item NO. |

Outer diameter*

Inner diameter

(mm)

|

Length & Purity |

| CS-AT-001 | 0.7*0.3 |

L≤1000mm

Al2O3=95%

Al2O3=99%

Al2O3=99.5%

|

CS-AT-018 | 7.0*4.5 |

L≤2500mm

Al2O3=95%

Al2O3=99%

Al2O3=99.5%

|

CS-AT-035 | 40*30 |

L≤2500mm

Al2O3=95%

Al2O3=99%

Al2O3=99.5%

|

| CS-AT-002 | 0.8*0.4 | CS-AT-019 | 8.0*4.0 | CS-AT-036 | 44*38 | |||

| CS-AT-003 | 0.9*0.4 | CS-AT-020 | 8.0*5.0 | CS-AT-037 | 50*40 | |||

| CS-AT-004 | 1.0*0.5 | CS-AT-021 | 9.0*6.0 | CS-AT-038 | 60*50 | |||

| CS-AT-005 | 1.1*0.6 | CS-AT-022 | 10.0*4.0 | CS-AT-039 | 70*60 |

L≤2000mm

Al2O3=95%

Al2O3=99%

Al2O3=99.5%

|

||

| CS-AT-006 | 1.2*0.6 | CS-AT-023 | 10.0*6.0 | CS-AT-040 | 80*70 | |||

| CS-AT-007 | 1.3*0.7 | CS-AT-024 | 10.0*7.0 | CS-AT-041 | 90*80 | |||

| CS-AT-008 | 1.4*0.8 | CS-AT-025 | 12.0*4.0 | CS-AT-042 | 100*90 | |||

| CS-AT-009 | 1.5*0.8 |

L≤2500mm

Al2O3=95%

Al2O3=99%

Al2O3=99.5%

|

CS-AT-026 | 12.0*8.0 | CS-AT-043 | 110*100 | ||

| CS-AT-010 | 2.0*1.0 | CS-AT-027 | 14.0*4.0 | CS-AT-044 | 120*110 | |||

| CS-AT-011 | 3.0*1.5 | CS-AT-028 | 14*10 | CS-AT-045 | 150*140 |

L≤1500mm

Al2O3=95%/

99%/99.5%

|

||

| CS-AT-012 | 3.0*2.0 | CS-AT-029 | 15*11 | CS-AT-046 | 200*190 | |||

| CS-AT-013 | 4.0*2.0 | CS-AT-030 | 16*12 | CS-AT-20216 | 37 32 |

20mm≤L≤2000mm

Al2O3=99%

|

||

| CS-AT-014 | 4.0*3.0 | CS-AT-031 | 18*14 | CS-AT-20217 | 38 31 | |||

| CS-AT-015 | 5.0*3.0 | CS-AT-032 | 20*15 | CS-AT-20218 | 45 38.5 | |||

| CS-AT-016 | 5.0*3.5 | CS-AT-033 | 25*19 | CS-AT-20219 | 46 38.5 | |||

| CS-AT-017 | 6.0*4.0 | CS-AT-034 | 30*25 | CS-AT-20220 | 60*30 | |||

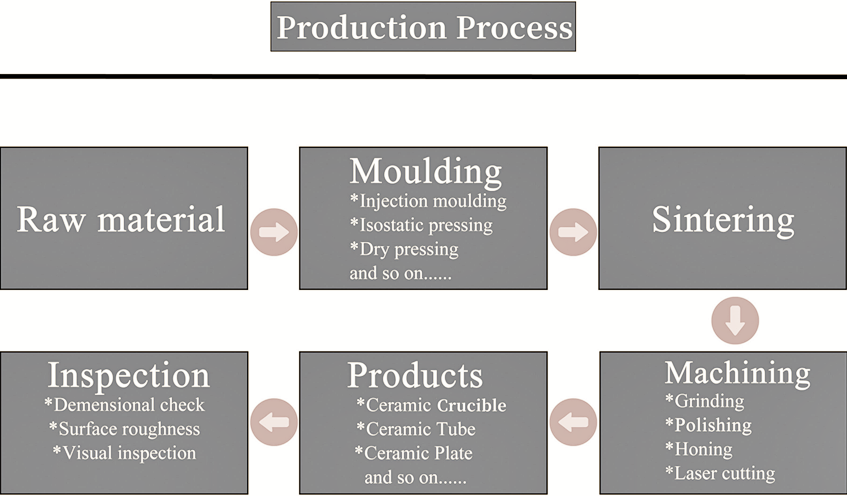

OEM/ODM is acceptable. Your goods will be produced exactly according to your drawings or inquiry.

The Versatile World of Alumina Tubes: Common Applications Unveiled

Industries involved in metallurgical processes, such as steel production, often require alumina tubes for use as furnace tubes, thermocouple protection tubes, and other high-temperature applications.

![]() How to Choose the Right Alumina Ceramic Furnace Tube for Your Application?

How to Choose the Right Alumina Ceramic Furnace Tube for Your Application?

Companies in the chemical processing industry often use alumina tubes for their excellent chemical resistance. These tubes can be used in various equipment, such as reactors, distillation columns, and pipelines, to handle corrosive substances.

The semiconductor industry relies on alumina tubes for applications such as insulating components, wafer handling boats, and crucibles used in crystal growth processes.

Power plants, including those involved in thermal, nuclear, or renewable energy generation, may require alumina tubes for applications such as high-temperature furnace tubes, boiler components, and heat exchangers.

Various research institutions, laboratories, and universities may need alumina tubes for experimental setups, high-temperature furnaces, thermal analysis equipment, and other scientific applications.

The aerospace and defense sectors utilize alumina tubes in applications such as rocket nozzles, high-temperature sensors, and insulation for electronic components due to their excellent thermal and electrical properties.

Manufacturers of glass and ceramic products use alumina tubes for kilns, glass melting furnaces, and other high-temperature processes where thermal stability and chemical resistance are crucial.

The aluminum oxide tubes' ability to withstand extreme temperatures without deformation or degradation.

Ceramic tubes are capable of handling rapid temperature changes without cracking or breaking.

The alumina ceramic tubes can resist chemical reactions or corrosion from molten metals or other substances present in the metallurgical processes.

The ceramic tubes are highly resistant to corrosive chemicals, acids, and bases.

These tubes have low levels of impurities to prevent contamination of the chemical processes.

They have a smooth surface that can minimize chemical buildup and facilitate easy cleaning.

Al2O3 tubes are provided with excellent electrical insulation to protect sensitive semiconductor components.

These ceramic tubes provide precise dimensions in order to ensure compatibility with semiconductor manufacturing equipment.

Our tubes can minimizing the release of volatile compounds that could contaminate the semiconductor manufacturing environment.

The ceramic tubes are capable of withstanding the high temperatures found in power generation processes.

Our tubes have sufficient mechanical strength to withstand the pressures and stresses present in power generation equipment.

They are resistant to corrosion from combustion byproducts, flue gases, or other corrosive elements encountered in power plants.

CSCERAMIC provide flexibility in producing ceramic tubes with specific dimensions, shapes, and configurations to meet research requirements.

Our ceramic tubes are able to withstand high temperatures and thermal cycling for various experimental setups.

These alumina ceramic tubes are compatible with other experimental apparatus, such as fittings, connectors, and holders.

Ceramic tubes offered by CSCERAMIC are capable of withstanding extreme temperatures encountered in aerospace applications.

The ceramic tubes are resistant to mechanical stress and vibration in aerospace and defense environments.

Our ceramic tubes can provide lightweight properties to meet the weight requirements of aerospace applications.

The alumina ceramic tubes are able to withstand rapid temperature changes involved in glass and ceramic production processes.

They are resistant to reactions with molten glass or ceramic materials.

Aluminum oxide ceramic tubes possess durability and extended lifespan to minimize frequent replacements and downtime.

Item

Test Condition

95% Al2O3

99% Al2O3

99.5% Al2O3

Physical properties

Density

g/cm3

>3.6

3.89

3.96

Moisture absorption

%

0

0

0

Mechanical properties

ROHS Hardness

≥85

≥89

≥89

Flexural strength

psiX103

20℃

358

550

550

Compressive strength

psiX103

20℃

2068(300)

2600(377)

2600(377)

Fracture toughness

Mpa.m3/2

K(l c)

4.3

5.6

6

Thermal properties

Maximum use temperature

℃

1450

1600

1650

Thermal expansion coefficient

1X10-6/℃

(25-1000℃)

7.6

7.9

8.2

Thermal shock resistance

℃

Tc

250

200

200

Thermal conductivity

w/mok

20℃

16

30

30.4

Electrical properties

Volume resistivity

Ohm/cm2

100℃

>1013

>1014

>1014

Dielectric breakdown strength

KV/mm

8.7(220)

8.7(220)

8.7(220)

Dielectric constant

(E)

1MHz25℃

9

9.7

9.7

Dielectric constant (100MHz)

(E)

9.5

a)

Q:

What is the maximum operating temperature of the alumina ceramic tubes, and can they withstand the thermal cycles in our furnace?

A:

The maximum operating temperature of our alumina ceramic tubes is typically around 1700°C, and they are designed to withstand rapid thermal cycles commonly encountered in furnaces.

b)

Q:

Are the alumina ceramic tubes resistant to chemical reactions with molten metals, such as aluminum or steel?

A:

Our alumina ceramic tubes exhibit excellent resistance to chemical reactions with molten metals, including aluminum and steel.

c)

Q:

Can the supplier provide certificates or test reports verifying the high-temperature and chemical resistance properties of the alumina ceramic tubes?

A:

We can provide comprehensive test reports and certificates demonstrating the high-temperature and chemical resistance properties of our alumina ceramic tubes.

a)

Q:

Are the alumina ceramic tubes compatible with aggressive chemicals like strong acids and alkalis commonly used in our processes?

A:

Our alumina ceramic tubes are highly compatible with aggressive chemicals, such as strong acids and alkalis commonly used in chemical processes.

b)

Q:

What is the expected lifespan of the alumina ceramic tubes when exposed to corrosive chemicals, and how often do they require replacement?

A:

The expected lifespan of our alumina ceramic tubes in corrosive chemical environments depends on the specific operating conditions but can range from several months to several years. Regular inspection and maintenance are recommended.

c)

Q:

Can the supplier customize the dimensions and configurations of the alumina ceramic tubes to fit our existing chemical processing equipment?

A:

We offer customization options for dimensions and configurations of alumina ceramic tubes to ensure seamless integration with your existing chemical processing equipment.

a)

Q:

Do the alumina ceramic tubes have low outgassing properties to prevent contamination of the cleanroom environment?

A:

Our alumina ceramic tubes have low outgassing properties, making them suitable for cleanroom environments in semiconductor manufacturing.

b)

Q:

Are the alumina ceramic tubes electrically insulating to ensure isolation between different components or parts?

A:

Alumina ceramic tubes provide excellent electrical insulation, ensuring effective isolation between different components or parts.

c)

Q:

Can the supplier provide documentation demonstrating the compatibility of alumina ceramic tubes with semiconductor fabrication processes, such as etching or deposition?

A:

We have extensive experience supplying alumina ceramic tubes to semiconductor fabrication processes and can provide documentation showcasing their compatibility with various manufacturing techniques.

a)

Q:

How does the thermal conductivity of alumina ceramic tubes impact heat transfer efficiency in our power generation system?

A:

The high thermal conductivity of our alumina ceramic tubes facilitates efficient heat transfer in power generation systems, improving overall performance.

b)

Q:

Can the alumina ceramic tubes withstand thermal shock caused by rapid temperature fluctuations during power generation operations?

A:

Our alumina ceramic tubes are specifically engineered to withstand thermal shock caused by rapid temperature fluctuations, ensuring reliable operation.

c)

Q:

What is the mechanical strength of the alumina ceramic tubes, and how do they perform under high-pressure conditions in power plants?

A:

With robust mechanical strength, our alumina ceramic tubes can withstand high-pressure conditions commonly encountered in power plants without deformation or failure.

a)

Q:

Can you offer customized alumina ceramic tubes with unique shapes or dimensions for our specific experimental setups?

A:

We specialize in offering customized alumina ceramic tubes with unique shapes or dimensions tailored to your specific experimental setups.

b)

Q:

What is the tolerance level for the dimensions of the alumina ceramic tubes, ensuring precise fitting with our research equipment?

A:

Our alumina ceramic tubes adhere to precise dimensional tolerances, ensuring precise fitting with your research equipment and minimizing any potential discrepancies.

c)

Q:

Are there any ongoing research projects or collaborations involving the development of novel alumina ceramic tube materials or applications?

A:

As a company focused on innovation, we actively participate in research projects and collaborations to develop advanced alumina ceramic tube materials and explore new applications.

a)

Q:

Do the alumina ceramic tubes meet the stringent requirements for weight reduction and high-temperature performance in aerospace applications?

A:

Our alumina ceramic tubes are designed to meet the stringent requirements of weight reduction and high-temperature performance in aerospace applications.

b)

Q:

Can the supplier provide traceability documentation and quality control measures to ensure the reliability of alumina ceramic tubes used in defense systems?

A:

We maintain strict traceability protocols and implement rigorous quality control measures to guarantee the reliability of alumina ceramic tubes used in defense systems.

c)

Q:

Are the alumina ceramic tubes resistant to vibration, shock, and other mechanical stresses experienced in aerospace and defense environments?

A:

Through extensive testing and validation, our alumina ceramic tubes demonstrate exceptional resistance to vibration, shock, and mechanical stresses, ensuring their suitability for aerospace and defense environments.

|

a) |

|

|

Q: |

What is the expected lifespan of alumina ceramic tubes used in glass or ceramic production processes, and how do they resist thermal cycling? |

|

A: |

Our alumina ceramic tubes have a prolonged lifespan in glass or ceramic production processes, exhibiting excellent resistance to thermal cycling. |

|

b) |

|

|

Q: |

Can the supplier provide references or case studies demonstrating the successful use of alumina ceramic tubes in glass or ceramic manufacturing applications? |

|

A: |

We can provide references and case studies showcasing successful applications of our alumina ceramic tubes in the glass and ceramics industry. |

|

c) |

|

|

Q: |

Are there any specific precautions or guidelines for handling, installing, or maintaining alumina ceramic tubes in the glass or ceramic industry? |

|

A: |

Our technical team can offer guidelines and recommendations for the proper handling, installation, and maintenance of alumina ceramic tubes in the glass and ceramics industry, ensuring optimal performance and longevity. |

1. Begin by vacuuming the outside of the tube to remove any debris or dust.

2. Use a mild detergent and scrub the tube with a soft cloth or brush.

3. Use a mild abrasive or a toothbrush to scrub the inside of the tube.

4. Rinse the inside and outside of the tube with warm water and a soft cloth.

5. Use a clean, lint-free cloth to dry it.

1. Visual inspection of the tube for any signs of damage or irregularities.

2. Measurement of the length, width, and thickness of the tube to check for accuracy.

3. Checking for any leaks or pinhole defects in the tube.

4. Testing for proper adhesion of the end cap to the tube.

5. Verification of the material and chemical composition of the tube.

Consistent quality

Ensuring reliable and consistent product quality with minimal defects.

Timely delivery

Meeting agreed-upon delivery schedules to avoid disruptions in the production or research processes.

Customization options

Offering the ability to produce tubes with specific dimensions, shapes, or compositions based on unique requirements.

Technical support

Providing expertise and assistance in selecting the most suitable tube specifications for the intended applications.

Competitive pricing

Offering competitive pricing structures that align with industry standards and market conditions.

Regulatory compliance

Ensuring compliance with relevant industry standards, certifications, and safety regulations.

Related product

Square Alumina Rod Alumina Ceramic Rods Length 1-2500mm

Square Alumina Rod Alumina Ceramic Rods Length 1-2500mm

Square alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Circle Alumina Rod Ceramic Rods Length 1-2500mm

Circle Alumina Rod Ceramic Rods Length 1-2500mm

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Triangle Alumina Rod Alumina Ceramic Rods

Triangle Alumina Rod Alumina Ceramic Rods

Triangle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Alumina Ceramic Pipes Thermocouple Insulator Ceramic Protection Tube(Closed one End) 1-2500mm

Alumina Ceramic Pipes Thermocouple Insulator Ceramic Protection Tube(Closed one End) 1-2500mm

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Thermocouple protection alumina tubes is mainly used to divide the different electrode of themometric element, they are lightweight and cost-effective, making them a great choice for cost-conscious applications.

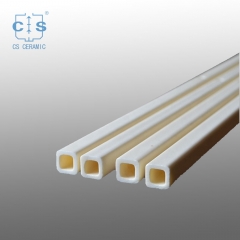

Square Alumina Ceramic Tubes One hole 1-2000mm

Square Alumina Ceramic Tubes One hole 1-2000mm

Square alumina tubes have high corrosion resistance, excellent thermal shock resistance, high thermal insulation. A variety of specifications available. OEM/ODM is acceptable.

OEM Alumina Rod Ceramic Rods

OEM Alumina Rod Ceramic Rods

Alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.All sizes can be customized and can be made into various complex shapes with high dimensional accuracy.

Small Alumina Ceramic Rods for Textile Machine

Small Alumina Ceramic Rods for Textile Machine

Alumina rods/tubes are lightweight and durable, making them suitable for use in a variety of textile applications. Available in a variety of sizes and shapes.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522