Brand :CSCERAMIC Factory :CS CERAMIC CO.,LTD

YB/T 4145-2006 (China)

Dedicated Carbon Sulfur Analyzing Crucible

1. Scope

This standard defines terminologies, structure, technical requirements, usage requirements, package, storage and transportation, marks, and quality certificates of dedicated carbon sulfur analyzing crucible.

This standard is applicable to dedicated carbon sulfur analyzing crucibles (hereinafter referred as to carbon sulfur crucibles) those made from natural mineral rock, by process of pressing and sintering.

2. Normative Reference Documents

Items in following documents are quoted so become items of this standard. Reference documents those with date noted, their later modification list (exclude corrigendum content) and revised edition are applicable to this standard. However, for application of latest edition of the documents, discussion and agreement according to this standard will be encouraged. Documents those without noted date, their latest edition is applicable to this standard.

GB/T 3299 Method for determination of water absorption of daily ceramics

GB/T 3301 Method for determination of volume deviation, diameter deviation, height deviation, weight deviation and defect size of daily ceramics

3. Terminologies and definitions

The following terminologies and definitions are applicable to this standard.

3.1 Edge-lack

Breakage in rim of crucible

3.2 Fissure

Tiny crack in surface of crucible

3.3 Crackle

Striped fault due to crack of the crucible body

3.4 Fusion hole

Cavity formed due to fusion of fusible content during the process of sintering.

3.5 Speaks or Iron spots

Colored stain in product surface, also called iron spots.

3.6 Heat-resistance

The capability that when put the crucible in high temperature furnace and raise the temperature to 1500℃, it can still keep unbroken.

3.7Ratio of crack

When put crucibles in high temperature furnace and raised the temperature to 1500℃, the ratio of crucible that crack appears.

3.8 Percent of water absorption

When the open pores of crucible body are saturated with water, the weight percentage of absorbed water to constant weight after drying the crucible at 110℃.

4、 Structure and codes

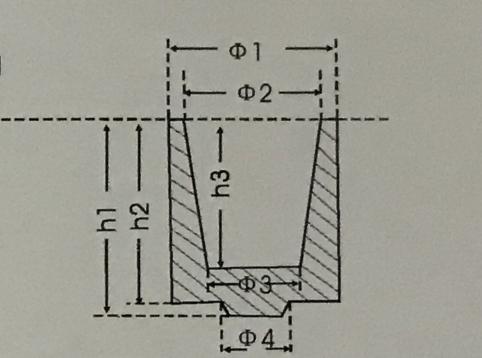

4.1 Main structure of crucible, see figure 1

4.2 Codes of crucibles are denoted by capital phonetic alphabet, PT for normal carbon sulfur crucible and CD for super low carbon sulfur crucible, the Arabic numerals are height and external diameter.

For example, PT 23*23 means normal carbon sulfur crucible with height of 23mm and external diameter of 23mm.

5、 Technical requirements

5.1 Raw material of carbon sulfur crucibles

5.1.1Usually mixture of Kaolin (Al2O3) and quartzite(SiO2) with certain ratio are used as raw material, main technical are as table 1.

|

ram material name |

Kaolin |

quartzite |

|

main chemical component |

|

|

|

(mass fraction)% |

Al₂O₃:70-80 |

SiO₂≥90 |

|

mixing ratio % |

40-60 |

40-60 |

5.1.3 Free carbon and impurity oxide in raw material should be removed before molding.

5.1.4 Before molding, carbon content in raw material should be less than 0.001% and sulfur content should be less than 0.001%.

5.2 Appearance and specification of crucible

5.2.1 Any crackle or defect like edge lack, fusion hole, fissure, iron sport that may affect normal use is not acceptable.

5.2.2 Surface defect of crucible should conform to the standard in table 2

|

surface defect assessing standard of carbon sulfur crucible |

|||||

|

Defect item |

range |

criterion |

defect item |

range |

criterion |

|

Edge lack |

length>2.0mm |

not acceptable |

fusion hole |

diameter ≤1.5mm |

no more than 3 |

|

width>1.5mm |

not acceptable |

depth ≤1.0mm |

no more than 3 |

||

|

length 1.0mm~2mm |

no more than 3 |

fissure |

internal surface |

not acceptable |

|

|

width 1.0mm~1.5mm |

no more than 3 |

external surface |

no limit |

||

|

length <1.0mm |

no limit |

crackle |

internal surface |

not acceptable |

|

|

width <1.0mm |

no limit |

|

external surface |

not acceptable |

|

5.2.3 Surface color and luster should be even, mottle or spot in internal surface are not acceptable. In external surface, total mottle area should be less than 10% of column superficial area.

5.2.4 dimension and allowable deviation of crucible should conform to the standard in

Table 3 dimension and allowable deviation of crucible

|

|

h1 |

h2 |

h3 |

⌀1 |

⌀2 |

⌀3 |

⌀4 |

|||||||

|

Cs ceramic crucible code |

basic dimension |

Allowable deviation |

basic dimension |

Allowable deviation |

basic dimension |

Allowable deviation |

basic dimension |

Allowable deviation |

basic dimension |

Allowable deviation |

basic dimension |

Allowable deviation |

basic dimension |

Allowable deviation |

|

PT 23*23 |

24 |

±1 ±0 |

23 |

±1 ±0 |

15 |

±0 |

23 |

±0.5 |

18 |

±0.5 |

14 |

±0.5 |

11 |

0-1 |

|

PT 25*25 |

26 |

±1 |

25 |

±1 |

18 |

±0.5 |

25 |

±0.5 |

19 |

±0.5 |

16 |

±1 |

11 |

0-1 |

|

CT 25*25 |

26 |

±1 |

25 |

±1 |

18 |

±0.5 |

25 |

±0.5 |

19 |

±0.5 |

18 |

±1 |

11 |

0-1 |

5.2.5 Thickness of crucible wall thickness should be uniform.

5.3 chemical performance

5.3.1 Baseline value of crucible: for normal crucible, carbon baseline value should be less than 0.0005%, and sulfur less than 0.0005%; for super low carbon sulfur crucible, carbon baseline value should be less than 0.0003%, and sulfur less than 0.0002%.

5.4 Physical performance

5.4.1 Thermal endurance of crucible: usually no higher than 150℃

5.4.2 Wracking ratio of crucible: less than 3%

5.4.3 Water absorption: larger than 3%

5.5 Inspection items

5.5.1 Carbon and sulfur element content in raw material

Inspection method of carbon and sulfur element content should conform to regulation in appendix A

5.5.2 Appearance inspection

Usually self-inspection is implemented under natural light, conform to requirements in table 2 (the measuring implement should with qualified precision)

5.5.3 Specification inspection

Main dimension inspection of crucible should conform to standard GB/T3301

5.5.4 Baseline value test

Baseline value test should conform to appendix A, carbon and sulfur content test with at least 40 samples continuously, and the arithmetic average will be regarded as carbon and sulfur baseline value of crucible.

5.5.5 Cracking ratio inspection

When test baseline value, cracking ratio can be inspected simultaneously, which is the number of crucibles that with crackle divided by total quantity of crucible.

5.5.6 thermal endurance test

Put crucibles in high temperature furnace, raise the temperature to 1500℃ and keep for 5 minutes. Then turn of the power, wait until the furnace drop to room temperature and take out the crucibles, deformation should not occur, and the dimension should conform to standard in table 3.

5.5.7 water absorption test

Water absorption test should be implemented as per standard GB/T3299.

5.5.8 Final inspection before delivery and judgement

Factory should implement sample inspection for every batch (kiln) of product, and sample quantity should be 0.1% of total product quantity, or no less than 100 pieces. If sample inspection is qualified, then the current batch (kiln) of products are judged as being qualified, and delivery is allowable. If sample inspection is not qualified, then extra tightened sample inspection can be implemented, sample 0.2% of total quantity or no less than 200 pieces and inspect, if still not qualified, then the current batch (kiln) of products are judged as being unqualified and delivery is now allowable.

6、Use requirements

Besides raw material and fabrication process, crucible baseline may also from absorption. Before using, influence of water, SO2 and CO2 to analyzing result should be avoided. For this purpose, two methods below are recommended.

Method 1, put carbon sulfur ceramic crucible in high temperature furnace, raise the temperature to 1200℃ and burn it for 2 hours, then take it out and get cooled, put into desiccator for demand (preservation time no longer than 4 hours)

Method 2, put carbon-sulfuric analysis crucible in tube-type crucible furnace, induce pure oxygen (purity 99.% or higher), and burn it no less than 1 hour at 1200℃.

info@csceramic.com

info@csceramic.com

+86 18273288522

+86 18273288522