1.Brief introduction

Due to influence of thermal history, various properties of polymers will change, especially thermal properties of crystalline polymers. Thermal history of polymer is affected by various factors such as preparation process, storage conditions, and usage environment. Usually, thermal history of materials is studied by thermal analysis and viscoelasticity measurement.

This paper introduces a case, in which PET has different viscoelastic properties due to different thermal history.

2. Experiment

The sample used this time was an extruded 0.5mm-thickness PET sheet. First, the sample was heated up for the first time until the cold crystallization process was completed, then cooled down slowly, and then heated up for the second time until the sample was about to but did not melt.

Instruments: SDM 5600H Rheological workstation and DMS 200 dynamic thermomechanical instrument.

Deformation mode: stretching.

Measurement frequency: 0.5, 1, 2, 5, 10 Hz;

Temperature program: first heating 150~200 ℃, second heating 150~250 ℃, heating rate 1℃/min, thermal analysis crucibles.

3. Measurement results

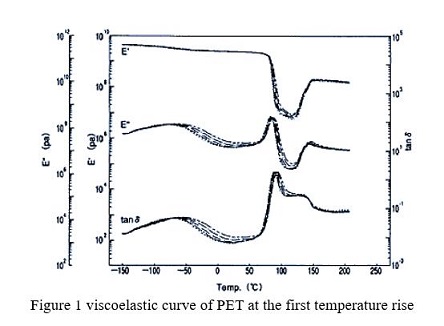

Fig.1 is viscoelastic curve of PET at the first temperature rise. This curve shows the E', E" and tanδ curves measured when temperature and frequency of the sample change simultaneously. It can be observed from the first heating curve (Figure 1) that, Alpha phase transition and Beta phase transition occurred near 80~90℃ and -150~20℃ respectively. Among them, Alpha phase transition belongs to glass transition and Beta phase transition belongs to local relaxation. In addition, it can also be observed that the peaks on the curves of E" and tanδ with the increase of E' near 120~140℃. Since PET is processed and formed by rapid cooling in the molten state, there are a lot of amorphous crystals, and the phase change peak at around 120~140 ℃ during the first heating process is cold crystallization of the amorphous part.

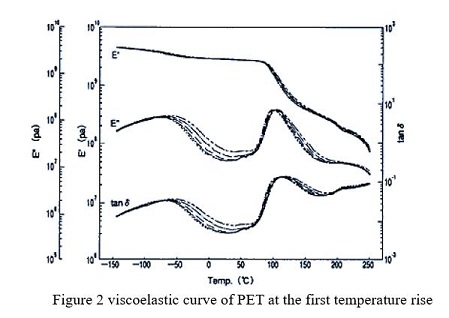

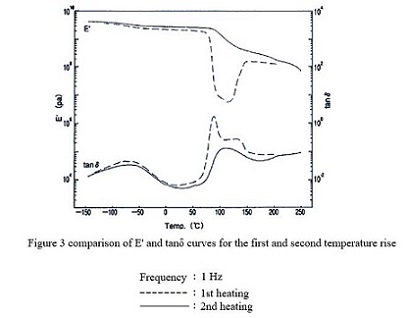

Fig.2 is a viscoelasticity curve of the second temperature rise. Fig.3 is the E' and tanδ curves for the first and second temperature rise. In fig.2 and fig.3, Alpha phase change and Beta phase change in the second heating process can be observed, but the cold crystallization process similar to that in the first heating process can not be observed. Since in the first heating process, sample was heated up until the cold crystallization process completed and then cooled slowly, so cold crystallization in the second heating process did not appear. Since the sample is cooled to a glassy state, the part where cold crystallization occurs will still show a crystalline state.

4. Summary

In this paper, influence of thermal history on PET dynamic viscoelastic properties, especially the difference between the cold crystallization phenomenon in the first and second heating curves is studied.

info@csceramic.com

info@csceramic.com

+86 18273288522

+86 18273288522