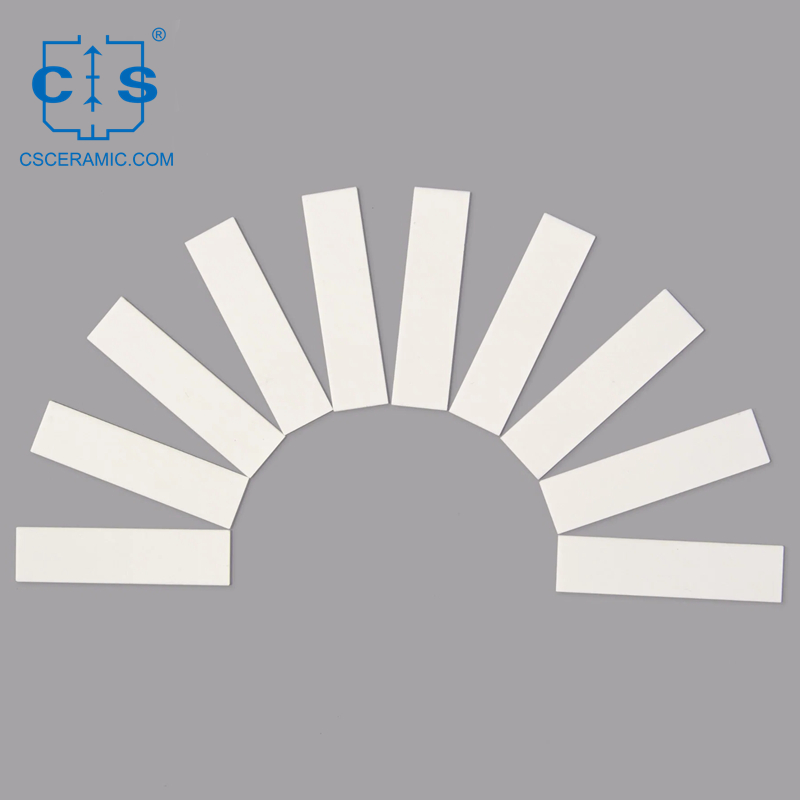

Alumina ceramic substrates embody the essence of durability and versatility, offering a myriad of applications that span across various industries. From the demanding realm of industrial processes to the intricate world of medical technology, these discs continue to prove their worth.

In industrial settings, alumina ceramic discs shine as a vital component due to their unparalleled resistance to high temperatures, corrosion, and wear. This resilience enables them to thrive in environments that involve abrasive materials, harsh chemicals, or extreme heat, ensuring uninterrupted operation.

The medical field, too, recognizes the significance of alumina ceramic discs. Their exceptional biocompatibility and hardness make them ideal for use in implants and prosthetic devices, providing patients with reliable and long-lasting solutions.

Moreover, alumina ceramic discs are highly sought after in the electronics industry for their superior electrical insulation and thermal conductivity properties, which are crucial for ensuring the safe and efficient operation of electronic devices.

With their remarkable versatility, longevity, and resistance to various elements, alumina ceramic discs have carved a niche for themselves in numerous industries, underlining their importance as an invaluable asset.

Properties of alumina ceramic Substrates

Uniquely positioned as a versatile engineering material, alumina ceramic substrates are celebrated for their exceptional blend of characteristics that cater to a wide array of applications. Core to their composition is aluminum oxide, a ceramic renowned for its exceptional hardness, strength, and steadfastness in extreme temperatures. Notably, these substrates possess a Mohs hardness rating of 9, positioning them just shy of diamond in terms of resistance to scratches, abrasion, and wear, thereby guaranteeing long-lasting durability in even the most challenging industrial and medical settings. Their thermal prowess, characterized by both superior heat conductivity and remarkable insulation abilities, renders them invaluable in high-temperature applications, including industrial furnaces, gas turbine components, and advanced electronics.

Advantages of using alumina ceramic Substrates

Alumina ceramic substrates boast a remarkable array of benefits that render them highly desirable across multiple industries. Their unparalleled durability and long service life, attributed to their exceptional hardness, strength, and resilience to wear, corrosion, and thermal cycling, are significant advantages. Versatility is another key feature, enabling customization to meet the precise needs of various applications, spanning automotive, aerospace, medical, and electronics fields. Their resistance to high temperatures, corrosive environments, and mechanical loads positions them as a top choice for demanding tasks. Additionally, their outstanding thermal management abilities, which blend efficient heat conduction with insulation capabilities, are invaluable in applications where temperature control is paramount, such as electronics and high-performance engines. Despite an initially higher cost, their long-term cost-effectiveness stems from reduced replacement cycles and maintenance expenses, making them a financially prudent choice for industries facing stringent operational challenges.

Applications of alumina ceramic substrates in the automotive industry

The automotive industry has long recognized the benefits of using alumina ceramic substrates in a variety of applications. These substrates are particularly well-suited for use in high-performance and high-stress automotive components due to their exceptional durability, thermal management capabilities, and resistance to wear and corrosion.

One of the primary applications of alumina ceramic substrates in the automotive industry is in engine components. The high thermal conductivity of these substrates allows for efficient heat transfer, which is crucial in the high-temperature environments of modern engines. Alumina ceramic substrates are commonly used in components such as spark plug insulators, glow plugs, and turbocharger housings, where their ability to withstand extreme temperatures and thermal cycling is essential.

Another important application of alumina ceramic substrates in the automotive industry is in braking systems. The exceptional hardness and wear resistance of these substrates make them an ideal choice for use in brake pads and discs, where they can provide superior performance and longevity compared to traditional materials. The low thermal conductivity of alumina ceramic substrates also helps to dissipate heat generated during braking, improving overall brake system efficiency and reducing the risk of overheating.

Alumina ceramic substrates are also finding increasing use in the manufacturing of automotive sensors and electronic components. Their excellent electrical insulation properties and resistance to harsh environmental conditions make them well-suited for use in sensors that monitor engine performance, emissions, and other critical parameters. Additionally, the thermal management capabilities of these substrates are crucial in the design of electronic control units and other automotive electronics, ensuring reliable and efficient operation.

Beyond engine and electronic components, alumina ceramic substrates are also utilized in the production of various structural and decorative automotive parts. Their exceptional hardness and resistance to wear and corrosion make them ideal for use in components such as gearbox housings, suspension parts, and even decorative trim pieces. The versatility and longevity of alumina ceramic substrates make them an increasingly valuable material in the ever-evolving automotive industry.

Conclusion

This article underscores the paramount significance of alumina ceramic substrates in automotive industries, attributed to their multi-faceted functionality and enduring durability. Their exceptional attributes, encompassing supreme hardness, exceptional thermal endurance, impeccable electrical non-conductivity, and formidable chemical resistance, have cemented their position as a vital element in numerous pivotal processes.

Glimpsing into the future, it is evident that the clamor for alumina ceramic substrates will intensify as industries endeavor to forge ahead with more proficient, steadfast, and eco-friendly solutions. The substrates' unparalleled capacity to thrive in the most arduous settings and function flawlessly under extreme circumstances will become increasingly sought-after as technological advancements escalate the need for elite materials.

info@csceramic.com

info@csceramic.com

+86 18273288522

+86 18273288522