Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

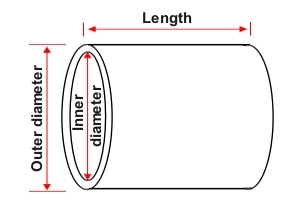

item no. :

CS-AT-047Material : Alumina ceramic

Length : 1-2500mm

Shape : One side open

1. Alumina tubes with low coefficient of thermal expansion of 10.3 x 10-6/K, ideal for use thermal stability in applications.

2. Alumina tubes have a low thermal conductivity of approximately 25 W/mK

3. Alumina tubes with high tensile strength and a modulus of elasticity of up to 200 GPa.

4. Alumina tubes resistance to corrosion and chemical attack, making them ideal for use in harsh environments.

5. Alumina tubes are non-toxic and do not release any hazardous substances, making them ideal for use in medical and food-grade applications.

6. High temperature resistance, 1600℃ in long use,1800℃ in short use (Al2O3≥99%).

1. Alumina tubes with one side end are made of high-grade alumina, offering superior heat and chemical resistance.

2. The design of the alumina tubes with one side end allows for maximum air flow and efficient heat transfer.

3. The alumina tubes with one side end are lightweight and easy to install, making them a great choice for a wide variety of applications.

4. The alumina tubes with one side end are designed for durability and long-term use, ensuring you get the most out of your investment.

Alumina Tube (One side open)

Item NO.

Length & Purity

Item NO.

Length & Purity

Item NO.

Length & Purity

CS-AT-049

4.0*2.5

CS-AT-065

25.4*19.05

CS-AT-10242

33*28

CS-AT-050

5.0*3.0

CS-AT-066

26.0*20.0

CS-AT-10243

34*18

CS-AT-051

6.0*3.5

CS-AT-067

28.0*22.0

CS-AT-10244

34*22

CS-AT-052

6.35*3.96

CS-AT-068

30.0*23.0

CS-AT-10245

34*23

CS-AT-053

7.95*4.78

CS-AT-10230

30*15

CS-AT-10246

34*30

CS-AT-054

8.0*5.5

CS-AT-10231

30*20

CS-AT-10247

35*27

CS-AT-055

9.53*6.35

CS-AT-10232

30*21

CS-AT-10248

35*29.5

CS-AT-056

10.0*6.0

CS-AT-10233

30*22

CS-AT-10249

36*30

CS-AT-057

10.0*7.0

CS-AT-10234

30*24

CS-AT-10250

36*31

CS-AT-058

11.13*7.95

CS-AT-10235

30*26

CS-AT-10251

37*29

CS-AT-059

12.0*8.0

CS-AT-10236

31*23

CS-AT-10252

37*31.5

CS-AT-060

12.7*8.9

CS-AT-10237

31*25

CS-AT-10253

37*32

CS-AT-061

20.0*15.0

CS-AT-10238

31*26

CS-AT-10254

38*31

CS-AT-062

22.23*15.88

CS-AT-10239

31*27

CS-AT-10255

45*38.5

CS-AT-063

23.83*17.48

CS-AT-10240

32*26

CS-AT-10256

46*38.5

CS-AT-064

25*18.8

CS-AT-10241

32*27

CS-AT-10257

60*30

20≤L≤2000

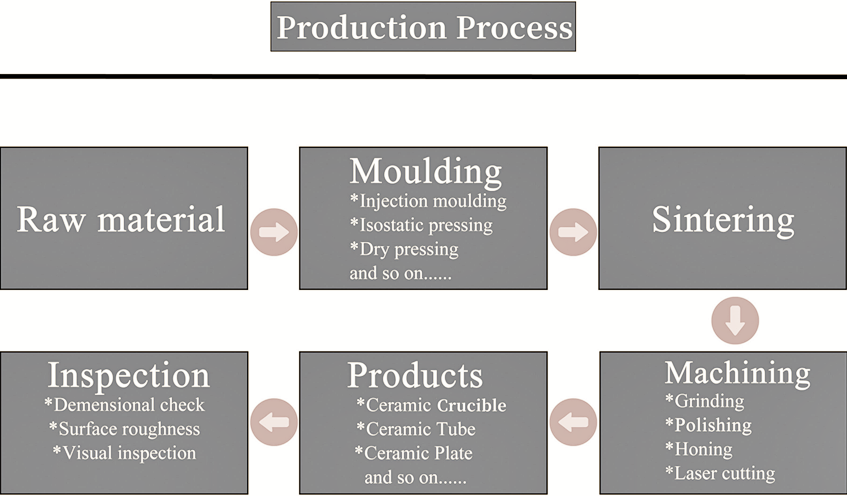

![]() How to make alumina ceramic tubes?

How to make alumina ceramic tubes?

1. Alumina tubes with one side end can be used in heat exchangers, where they provide an efficient method of heat transfer.

2. It can also be used as a catalyst support in chemical reactions, as they provide an inert surface material.

3. It can be employed in the production of medical devices, such as stents, where their inert nature and resistance to corrosion are ideal.

4. The alumina tubes can be used as an electrical insulator, particularly in high voltage applications.

5. Alumina tubes with one side end can be used in the manufacture of semiconductor devices such as transistors, diodes and integrated circuits.

6. The tubes can also be employed as a support for chromatography columns, where their inert nature and high temperature resistance provide an ideal material for this purpose.

7. Alumina tubes with one side end can be used in fuel cells, where their inert nature and thermal stability provide an ideal material for this application.

8. It can also be used as a support for electrodes in electrochemical cells, where their inert nature and electrical resistance make them an ideal material.

| Item | Test Condition | 95% Al2O3 | 99% Al2O3 | 99.5% Al2O3 | ||

| Physical properties | Density | g/cm3 | >3.6 | 3.89 | 3.96 | |

| Moisture absorption | % | 0 | 0 | 0 | ||

| Mechanical properties | ROHS Hardness | ≥85 | ≥89 | ≥89 | ||

| Flexural strength | psiX103 | 20℃ | 358 | 550 | 550 | |

| Compressive strength | psiX103 | 20℃ | 2068(300) | 2600(377) | 2600(377) | |

| Fracture toughness | Mpa.m3/2 | K(l c) | 4.3 | 5.6 | 6 | |

| Thermal properties | Maximum use temperature | ℃ | 1450 | 1600 | 1650 | |

| Thermal expansion coefficient | 1X10-6/℃ | (25-1000℃) | 7.6 | 7.9 | 8.2 | |

| Thermal shock resistance | ℃ | Tc | 250 | 200 | 200 | |

| Thermal conductivity | w/mok | 20℃ | 16 | 30 | 30.4 | |

| Electrical properties | Volume resistivity | Ohm/cm2 | 100℃ | >1013 | >1014 | >1014 |

| Dielectric breakdown strength | KV/mm | 8.7(220) | 8.7(220) | 8.7(220) | ||

| Dielectric constant | (E) | 1MHz25℃ | 9 | 9.7 | 9.7 | |

| Dielectric constant (100MHz) | (E) | 9.5 | ||||

Q1. What information should we supply to get a quote?

Please offer the specification of ceramic tube for furnace, such as shape, dimension, quantity, application etc.

Q2. What type or material should we choose?

If you are not sure about the type/material needed, please kindly supply more details about working condition and application. Then our technical staff will check and offer you the most suitable type or material.

Q3. Is the alumina tube with one side end available in different colors?

Yes, the alumina tube with one side end is available in a variety of colors. Please contact us for more information.

Q4.Is the alumina tube with one side end compatible with other materials?

Yes, the alumina tube with one side end is compatible with other materials such as glass, quartz, and ceramics.

Q5. What is the lead time for the alumina tube with one side end?

The lead time for the alumina tube with one side end is dependent on the size and quantity required. Please contact us for more infor.

1. Begin by vacuuming the outside of the tube to remove any debris or dust.

2. Use a mild detergent and scrub the tube with a soft cloth or brush.

3. Use a mild abrasive or a toothbrush to scrub the inside of the tube.

4. Rinse the inside and outside of the tube with warm water and a soft cloth.

5. Use a clean, lint-free cloth to dry it.

1. Visual inspection of the tube for any signs of damage or irregularities.

2. Measurement of the length, width, and thickness of the tube to check for accuracy.

3. Confirmation that the end of the tube is properly sealed.

4. Checking for any leaks or pinhole defects in the tube.

5. Testing for proper adhesion of the end cap to the tube.

6. Verification of the material and chemical composition of the tube.

1. We offer personalized and customized services to meet your individual needs.

2. We are experienced professionals with a proven track record of success.

3. We provide excellent customer service and timely responses to all inquiries.

4. We have competitive rates and work to ensure that you get the best value for your money.

5. We use the latest technology and tools to ensure that your project is completed to the highest standards.

6. We take pride in our work and strive for complete customer satisfaction.

Square Alumina Rod Alumina Ceramic Rods Length 1-2500mm

Square Alumina Rod Alumina Ceramic Rods Length 1-2500mm

Square alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Circle Alumina Rod Ceramic Rods Length 1-2500mm

Circle Alumina Rod Ceramic Rods Length 1-2500mm

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Triangle Alumina Rod Alumina Ceramic Rods

Triangle Alumina Rod Alumina Ceramic Rods

Triangle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Thermocouple protection alumina tubes is mainly used to divide the different electrode of themometric element, they are lightweight and cost-effective, making them a great choice for cost-conscious applications.

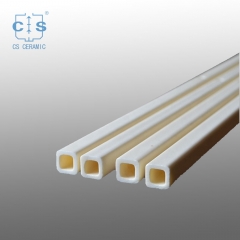

Square Alumina Ceramic Tubes One hole 1-2000mm

Square Alumina Ceramic Tubes One hole 1-2000mm

Square alumina tubes have high corrosion resistance, excellent thermal shock resistance, high thermal insulation. A variety of specifications available. OEM/ODM is acceptable.

Alumina Ceramic Tubes/Pipes Both Open Single Bore Tubes Length 1mm-2500mm

Alumina Ceramic Tubes/Pipes Both Open Single Bore Tubes Length 1mm-2500mm

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

OEM Alumina Rod Ceramic Rods

OEM Alumina Rod Ceramic Rods

Alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.All sizes can be customized and can be made into various complex shapes with high dimensional accuracy.

Small Alumina Ceramic Rods for Textile Machine

Small Alumina Ceramic Rods for Textile Machine

Alumina rods/tubes are lightweight and durable, making them suitable for use in a variety of textile applications. Available in a variety of sizes and shapes.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522