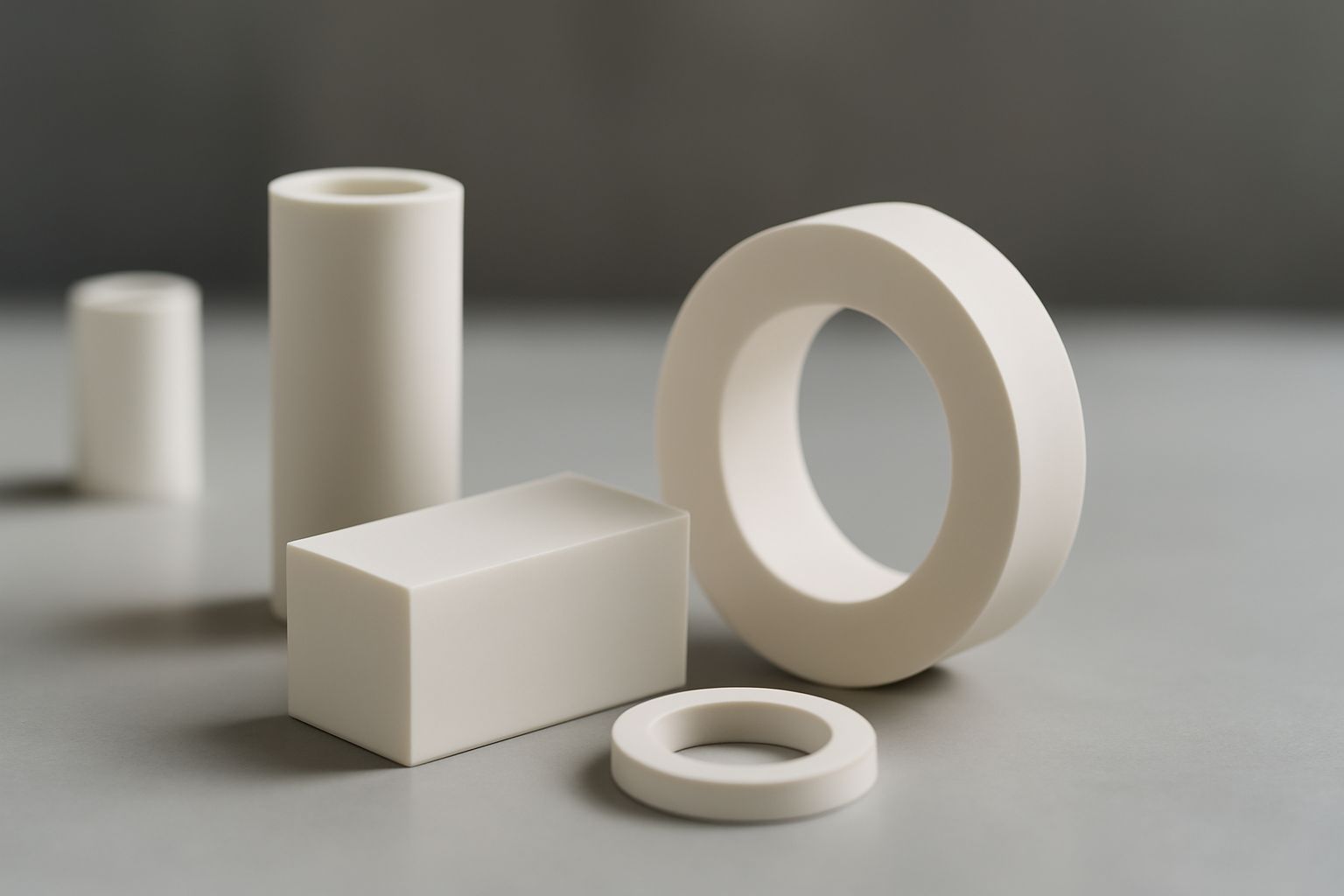

CSCERAMIC delivers high-precision custom alumina ceramic solutions backed by fast prototyping, engineering support, and reliable B2B service. OEM buyers benefit through tailored designs, tight tolerances, and dependable on-time shipment—even for complex specs.

How Does CSCERAMIC Support Engineering From Spec to Delivery?

CSCERAMIC provides seamless engineering collaboration, from early specification refinement through final shipment of custom alumina ceramic components. Our project engineers work directly with OEM and industrial clients to optimize drawings, recommend appropriate material purity (such as ≥99.7% Al2O3), and advise on design-for-manufacturability. We routinely supply detailed 2D/3D proposals, and proactively communicate all critical tolerances and QA checkpoints during quoting.

From my experience, this "engineer-to-order" process dramatically reduces delays and risks. We have helped EU automation clients reduce late revisions by 30% and avoid downstream rework in 2024 by mapping critical-to-function tolerances in the initial RFQ. Our documented workflow ensures each part meets drawing and quality targets before shipment, with inspection photos and data reports as backup.

| Process Step | CSCERAMIC Service | Buyer Benefit |

|---|---|---|

| Specification Review | DXF/3D formats, tolerances, QA discussion | Accurate quote, early risk disclosure |

| Prototyping/Drawing Optimization | Engineering consultation, DFM advice, simulation on request | Reduced design errors, faster DVT |

| Quality Control & Pre-shipment | Full inspection, illustrated QC data and test reports | Assured compliance, smooth acceptance |

What Technical Services and Support Are Available for OEM Projects?

OEM projects using alumina ceramic require advanced technical support for reliable outcomes. At CSCERAMIC, I frequently provide material selection guidance, review compatibility with chemical and temperature environments, and consult on production feasibility of complex geometries. We also support third-party certification needs for industrial buyers, and provide full documentation for each custom order.

Notably, clients in automotive sensor manufacturing have relied on our prompt technical response to refine tolerances and validate 99.7% purity requirements—cutting qualification time by 20% in recent projects. For new OEM launches, our engineers participate in early reviews, helping clients select the right alumina grade and optimize design for both performance and cost.

| Service Provided | Typical Use Case | Reference |

|---|---|---|

| Material Recommendation | Selection by application (insulation, wear resistance) | Alumina technical data |

| Engineering Drawing Review | Tolerance check, DFM feedback | Kyocera application cases |

| Rapid Prototyping | Small lot, proofing, trial production | ScienceDirect: Alumina ceramics |

How Fast Can CSCERAMIC Deliver Samples and Standard Alumina Parts?

CSCERAMIC is recognized for speedy sample turnarounds and high availability of standard alumina ceramic products. For stocked parts such as rods and tubes, I routinely ship within 24 hours after PO confirmation. For custom pieces, simple prototypes are often ready in under 14 working days, and batch manufacturing is completed in 3–5 weeks depending on complexity.

Recent feedback shows that our expedited sample dispatch reduced OEM project delays for a German automation client by nearly three weeks, compared to prior suppliers with 8+ week cycles. Our digital workflow and local inventory ensure urgent B2B projects meet critical development schedules.

| Item Type | Lead Time | Remarks |

|---|---|---|

| Standard Alumina Rod/Tube | 24–48 hrs (in stock) | Rapid FedEx/DHL shipping |

| Custom Prototyping | 10–14 working days | Complexity-dependent |

| Batch Production (OEM) | 3–5 weeks | Full QA, fastest via DDP |

How Do Buyers Leverage Expert Guidance When Selecting Alumina Ceramics?

Expert application support at CSCERAMIC empowers buyers to specify the most cost-effective and performance-matched alumina grade for each scenario. Through one-on-one consultations, we help clients compare physical, electrical, and thermal properties, offering reference data and technical certificates as needed. Our team explains critical differences—such as 99.7% purity versus 95%—for each application, enabling optimal cost and longevity.

Industrial buyers appreciate the ability to evaluate lifetime cost, test options, and analyze common failure modes before placing orders. For instance, we recently assisted a North American lab instrument firm to reduce returns by advising on exact surface roughness parameters, based on field failure analysis. This approach results in more confident selections and improved device performance.

| Key Factor | How CSCERAMIC Supports | Buyer Outcome |

|---|---|---|

| Material Purity & Certification | Advises ≥99.7%/95% based on use, provides test report | Fewer part failures, traceable QA |

| Optimal Tolerances & Finish | Guides on achievable tolerances (±0.02mm), recommends polish | Improved fit, lower scrap rate |

| Life-Cycle Cost Analysis | Shares typical use failures, provides references | Better ROI, confident selection |

CSCERAMIC stands out in custom alumina ceramic by aligning deep engineering support with fast delivery and continuous technical guidance. Industrial and OEM buyers benefit from more accurate, efficient, and cost-effective ceramic sourcing.

Need custom alumina ceramics or fast B2B engineering support?

info@csceramic.com

info@csceramic.com

+86 18273288522

+86 18273288522