Aluminum Nitride (AlN) ceramics

Aluminum Nitride (AlN) ceramics have recently become a prevalent material for a wide range of applications due to their combination of desirable properties. AlN is a hard, low-density material with excellent thermal and electrical insulation properties, making it an ideal choice for many applications. One of the primary advantages of AlN is its high thermal conductivity. This makes it an ideal material for heat sinks and heat spreaders, as well as for applications that require efficient thermal management. AlN also has excellent electrical insulation properties, making it an ideal material for use in electronics, medical devices, and high-temperature insulation.

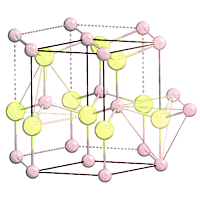

What is Aluminum Nitride?

Aluminum Nitride (AlN) is a covalently bonded ceramic material formed from the two abundant elements, aluminum and nitrogen. It is highly stable in an atmosphere that is inert at temperatures over 2000°C and has a remarkable combination of properties, boasting high thermal conductivity, electrical insulation properties and strong dielectric strength. This makes it an indispensable material for a variety of applications in the fields of electronics, optics, lighting, renewable energy, thermal management and electrical applications.

Aluminum Nitride (AlN)

It is also an in-demand alternative to Beryllium Oxide (BeO) in the semiconductor industry, as machining it does not pose a health hazard. Furthermore, Aluminum Nitride's coefficient of thermal expansion and electrical insulation properties match those of Silicon wafer materials, which makes it a great choice for electronics applications that are subject to intense temperatures and require effective heat dissipation.

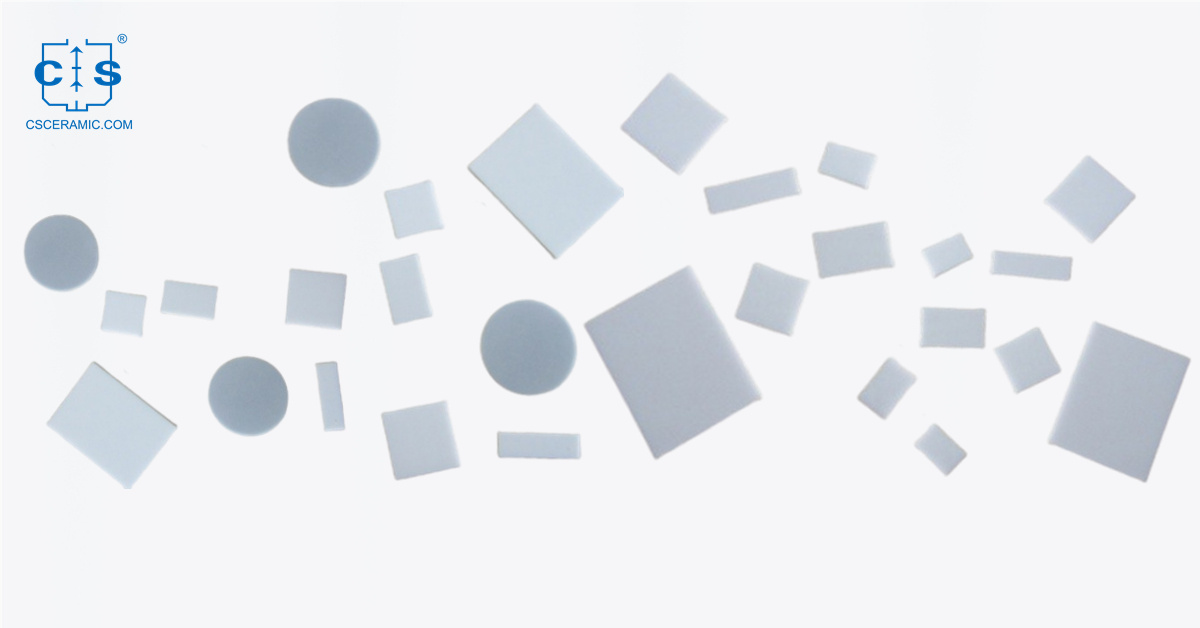

What is Aluminium Nitride used for?

l Heat sinks & Heat spreaders

l Electrical insulators

l Chucks and clamp rings for semiconductor processing equipment

l Silicon wafer handling and processing

l Substrates for electronic packages

l Chip carriers for sensors and detectors

l Laser heat management components

l Molten metal fixtures

l Packaging for microwave devices

l Opto electronic devices

l Serves as substrates and insulators microelectronic packages

AlN's superior characteristics make it the perfect choice for many industrial and commercial applications.

Why is AlN a in-demand material for substrate and thermal management applications?

Aluminum Nitride is a one-of-a-kind ceramic material that offers both excellent thermal conductivity and high electrical resistivity. While Beryllium Oxide and cubic Boron Nitride also possess high thermal conductivity, usage of BeO is limited due to its toxicity and it is quite challenging to manufacture c-BN.

The capacity of a material to move heat while under the effect of a temperature differential is known as "thermal conductivity". In dielectrics such as AlN, heat transmission happens through lattice oscillations (or "phonons"). Elements having a straightforward composition, covalent bonding and low atomic mass normally demonstrate elevated thermal conductivity.

The thermal conductivity of a material is impacted by elements that hamper phonon dissemination. Such factors include temperature, impurities, pore size and placement, grain size, compositional homogeneity and alignment, all of which can significantly affect the lattice vibrations and, subsequently, the thermal conductivity.

The thermal conductivity of aluminium nitride, theoretically, is approximately 280 Wm-1K-1. The real thermal conductivity, on the other hand, is dependent on the processing parameters and the raw material quality. The incorporation of oxygen impurities into the lattice is a great disadvantage. As oxyge-n displaces nitrogen in the lattice, it forms vacancies that impede phonon propagation and scatter the phonons, thus leading to a decrease in thermal conductivity.

In conclusion, AlN ceramics offer a combination of desirable properties that make it an ideal choice for many applications. Its high thermal conductivity and electrical insulation properties make it ideal for heat sinks and heat spreaders, while its low coefficient of thermal expansion makes it suitable for semiconductor fabrication equipment.

Thank you for reading. We invite you to visit CSCERAMIC for more information if you would like to learn more about industrial ceramic material and the advanced range of ceramic products we offer.

info@csceramic.com

info@csceramic.com

+86 18273288522

+86 18273288522