|

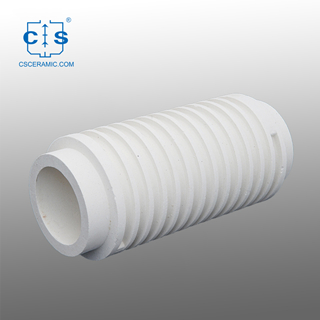

Alumina ceramics, renowned for their excellent conductivity, mechanical strength, and high-temperature resistance, find extensive applications across various domains such as electronics, electrical engineering, mechanics, textiles, aerospace, and more. However, due to their high sintering temperature requirements, these ceramics consume substantial energy and necessitate specialized thermal equipment. Consequently, the utilization of alumina ceramics is somewhat constrained by these factors. |

To effectively lower the sintering temperature of alumina ceramics, we can explore employing distinctive sintering techniques. In this context, can the utilization of hot pressing sintering technology contribute to the reduction of sintering temperatures for alumina ceramics?

Hot Pressing Sintering Technique: A Game-Changer for Alumina Ceramics

The hot pressing sintering process involves applying pressure while heating the compacted ceramic powder. This technique not only relies on diffusion for mass transfer during sintering but also capitalizes on plastic deformation, significantly lowering the required sintering temperature compared to conventional pressureless sintering. As a crucial technology, hot pressing sintering presents a pathway to decreasing the sintering temperature of alumina ceramics. Whereas typical atmospheric pressure sintering necessitates temperatures above 1800°C for alumina ceramics, hot pressing sintering can achieve effective sintering at around 1500°C.

Synergizing Techniques for Optimal Results

In practical manufacturing scenarios, achieving optimal economic efficiency often involves the synergistic use of various low-temperature sintering techniques. Among these, the method of incorporating auxiliary combustion additives stands out for its cost-effectiveness, impressive outcomes, and straightforward implementation. Additionally, from a material perspective, alumina ceramics' mechanical and electrical properties witness significant enhancement through techniques like doping and modification. By substituting ceramics with lower alumina content for those with higher content, companies can frequently employ this effective approach to reduce sintering temperatures for alumina ceramics.

A Holistic Approach to Lower Sintering Temperatures

To summarize, it is evident that the application of hot pressing sintering technology indeed contributes to the partial reduction of sintering temperatures for alumina ceramics. Beyond hot pressing sintering, other avenues for achieving lower sintering temperatures exist as well. These include optimizing formulation systems, enhancing the fineness and reactivity of raw material powders, and incorporating sintering aids. By adopting a holistic strategy that combines these techniques, manufacturers can significantly diminish the sintering temperature requirements for alumina ceramics.

Conclusion

In conclusion, the utilization of hot pressing sintering technology represents a remarkable advancement in the realm of alumina ceramics. This technique's ability to lower sintering temperatures, coupled with other synergistic approaches, paves the way for enhanced energy efficiency, cost savings, and expanded application possibilities for alumina ceramics. As the field of ceramic engineering continues to evolve, these innovations hold the promise of reshaping industries and driving further advancements in material science.

Thank you for reading. We invite you to visit CSCERAMIC for more information if you would like to learn more about industrial ceramic material and the advanced range of ceramic products we offer.

info@csceramic.com

info@csceramic.com

+86 18273288522

+86 18273288522