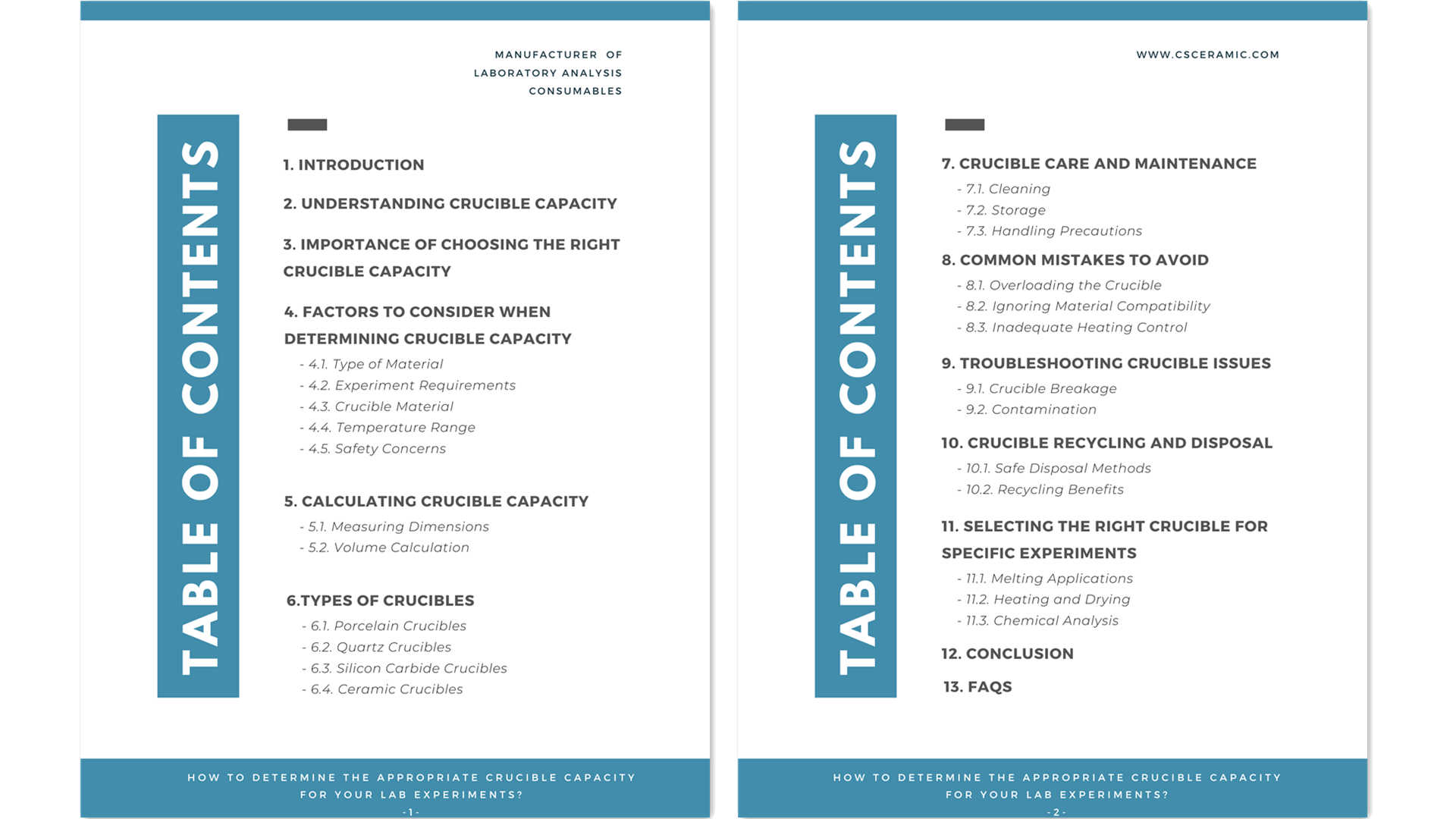

How to Determine the Appropriate Crucible Capacity for Your Lab Experiments?

In laboratory experiments, crucibles play a crucial role in holding and processing materials at high temperatures. Choosing the right crucible capacity is essential to ensure successful experiments and accurate results. This article provides a comprehensive guide on determining the appropriate crucible capacity for your lab experiments, taking into account various factors that influence the selection process.

2 Understanding Crucible Capacity

Crucible capacity refers to the maximum volume a crucible can hold without overflowing or compromising the quality of the experiment. Crucibles come in various sizes, shapes, and materials, each designed to meet specific experimental needs. Determining the ideal crucible capacity is a critical step in ensuring the experiment's success.

3 Importance of Choosing the Right Crucible Capacity

Selecting the correct crucible capacity is vital for several reasons:

Avoiding Material Waste

An oversized crucible can lead to unnecessary material waste, affecting the overall efficiency and cost-effectiveness of the experiment.

Accurate Results

Using an appropriately sized crucible ensures the accurate measurement of reactions and materials, leading to reliable results.

Safety

Overloading a crucible may lead to spillage or accidents, jeopardizing the safety of lab personnel.

4 Factors to Consider When Determining Crucible Capacity

When determining the appropriate crucible capacity for your lab experiments, several crucial factors must be taken into account to ensure the success and accuracy of your results.

Type of Material

The type of material you intend to use in your experiment is a significant factor in selecting the right crucible capacity. Different materials have varying properties, including their density and volume, which will affect the required crucible size. Consider the physical state of the material, such as solid, liquid, or powder, and estimate the volume it will occupy during the experiment.

Experiment Requirements

The specific requirements of your experiment will also influence the crucible capacity. Consider the purpose of the experiment, whether it involves heating, melting, chemical reactions, or other processes. Different experiments may require varying amounts of the material, and this should be factored in when choosing the appropriate crucible size.

Crucible Material

Crucibles come in different materials, each with its own unique properties. For example,porcelain crucibles are suitable for general use and can withstand high temperatures.Quartz crucibles are ideal for experiments involving strong acids and alkalis due to their excellent chemical resistance.Silicon carbide crucibles, on the other hand, are preferred for high-temperature applications and metal alloy experiments. Consider the properties of the material being used and match it with the appropriate crucible material for optimal performance and accurate results.

Temperature Range

The temperature range of your experiment is a critical factor in determining the crucible capacity. Different materials have varying temperature limits, and you must select a crucible that can withstand the highest temperature reached during the experiment without compromising its integrity. Using a crucible with a lower temperature tolerance may lead to breakage or failure, resulting in data loss and potential hazards.

Safety Concerns

Safety should always be a top priority in any laboratory experiment. When selecting the crucible capacity, consider the safety aspects, such as how much material can be safely handled and heated within the crucible without spillage or accidents. Overloading a crucible can be hazardous, leading to mishaps or the material coming into contact with lab personnel. Ensuring the crucible capacity aligns with safe handling practices is essential to avoid any potential risks.

5 Calculating Crucible Capacity

Calculating the crucible capacity involves accurately determining the volume of material it can hold without overflowing. To calculate the crucible capacity, follow these steps:

Measuring Dimensions

Measure the inner dimensions of the crucible, including the height and diameter. Use a ruler or calipers to obtain precise measurements. Note that crucibles may have varying shapes, so be sure to measure accordingly.

Volume Calculation

Once you have the measurements, use the appropriate formula to calculate the crucible's volume. The volume of a cylindrical crucible can be calculated using the formula V =π* r²* h, where V is the volume,π(pi) is a mathematical constant approximately equal to 3.14159, r is the radius of the crucible, and h is the height of the crucible. For crucibles with different shapes, use the corresponding formula to calculate the volume.

By accurately calculating the crucible capacity, you can ensure that the amount of material used in the experiment is appropriate for the crucible size, leading to successful and precise results.

6 Types of Crucibles

Crucibles come in various materials, each offering unique properties suited for specific laboratory applications. Understanding the different types of crucibles will help you make an informed choice based on the requirements of your experiments.

Porcelain Crucibles

Porcelain crucibles are among the most commonly used crucibles in laboratories. They are versatile, affordable, and can withstand high temperatures, making them suitable for a wide range of applications. Porcelain crucibles are ideal for general laboratory work, such as heating and evaporation processes. They are also chemically inert, which ensures minimal interference with reactions and accurate results in various experiments.

Quartz Crucibles

Quartz crucibles are known for their exceptional resistance to high temperatures and chemical reactivity. They are suitable for experiments involving strong acids, alkalis, and other corrosive substances. Quartz crucibles are often used in applications like sample preparation for trace element analysis, where chemical purity is crucial. They are transparent to infrared radiation, making them valuable in certain spectroscopic studies.

Silicon Carbide Crucibles

Silicon carbide crucibles are the preferred choice for high-temperature applications and metallurgical processes. They can withstand extreme heat and are highly resistant to thermal shock, making them ideal for processes like melting metals, alloys, and other materials at high temperatures. Silicon carbide crucibles are commonly used in foundries and metal casting industries, where they provide excellent performance and durability in harsh conditions.

Alumina Crucibles

Alumina crucibles are used in applications that require resistance to rapid temperature changes. They are less prone to thermal shock and can handle significant temperature variations without cracking. Alumina crucibles find application in processes like calcination, ashing, and other heating applications. Their stability and ability to withstand thermal cycling make them suitable for extended use in various laboratory experiments.

7 Crucible Care and Maintenance

Proper care and maintenance of crucibles are crucial to their longevity and performance:

Cleaning

Clean crucibles thoroughly after each use to prevent contamination.

Storage

Store crucibles in a dry and safe environment to avoid damage.

Handling Precautions

Handle crucibles with care to prevent breakage and potential injury.

8 Common Mistakes to Avoid

Avoid these common errors to ensure successful experiments:

Overloading the Crucible

Do not exceed the recommended capacity, as it may lead to spills or uneven heating.

Ignoring Material Compatibility

Consider the crucible material's compatibility with the substances used to avoid reactions or contamination.

Inadequate Heating Control

Improper heating can cause thermal stress and crack the crucible.

9 Troubleshooting Crucible Issues

Address these common crucible issues for a smooth experiment:

Crucible Breakage

Understand the reasons for crucible breakage and implement preventive measures.

Contamination

Take precautions to avoid contamination of materials during the experiment.

10 Crucible Recycling and Disposal

Learn the proper methods for recycling and disposing of crucibles responsibly:

Safe Disposal Methods

Dispose of used crucibles following laboratory waste disposal guidelines.

Recycling Benefits

Explore the benefits of recycling crucibles to reduce environmental impact.

11 Selecting the Right Crucible for Specific Experiments

Choosing the correct crucible for specific experiments is essential to ensure the success and accuracy of the results. Consider the following factors when selecting the right crucible for your experiment:

Melting Applications

If your experiment involves melting metals, alloys, or other materials, consider using a silicon carbide crucible. Silicon carbide's exceptional heat resistance and durability make it ideal for high-temperature melting processes without compromising the crucible's integrity.

Heating and Drying

For general heating and drying applications, a porcelain crucible is a suitable choice. Porcelain crucibles can withstand high temperatures and offer good chemical inertness, making them versatile for a wide range of heating and evaporation processes.

Chemical Analysis

In experiments where chemical purity and resistance to reactivity are critical, quartz crucibles are preferred. Quartz provides excellent chemical resistance, making it ideal for applications involving strong acids and alkalis. It is commonly used in sample preparation for accurate chemical analysis.

General Laboratory Work

For general laboratory work that does not involve extreme heat or corrosive substances, porcelain crucibles offer a cost-effective and versatile option. They are widely used in various laboratory processes and are suitable for routine experiments.

Specialized Applications

In some cases, specialized crucibles made from unique materials may be necessary for specific applications. For instance, certain experiments may require crucibles made from platinum or other rare metals for their exceptional properties and resistance to chemical reactions.

By carefully considering the type of experiment and its specific requirements, you can select the most appropriate crucible, ensuring reliable and successful results in your laboratory work. Always ensure that the chosen crucible material can handle the intended temperature and chemical conditions without compromising the accuracy of your experiment.

12 Conclusion

Choosing the appropriate crucible capacity is a crucial step in ensuring the success of your lab experiments. Consider the type of material, experiment requirements, crucible material, temperature range, and safety concerns when making your selection. Properly calculate the crucible capacity, and take care of its maintenance to ensure longevity and accurate results. By following these guidelines, you can optimize your lab experiments and achieve reliable outcomes.

13 FAQs

Q:How do I determine the appropriate crucible size for my experiment?

A:To determine the right crucible size, measure the volume of the material to be used and ensure the crucible capacity is slightly larger to allow for expansion.

Q:Can I reuse a crucible after one experiment?

A:Yes, you can reuse a crucible, but ensure it's thoroughly cleaned and in good condition before reuse.

Q:What is the best crucible material for high-temperature applications?

A:Silicon carbide crucibles are ideal for high-temperature applications due to their excellent heat resistance.

Q:How do I prevent crucible breakage during heating?

A:Avoid sudden temperature changes and use a crucible appropriate for the heating method to prevent breakage.

Q:Is it necessary to preheat a crucible before use?

A:Preheating can help remove any moisture and contaminants from the crucible, ensuring a successful experiment.

Thank you for reading. We invite you to visit CSCERAMIC for more information if you would like to learn more about industrial ceramic material and the advanced range of ceramic products we offer.

info@csceramic.com

info@csceramic.com

+86 18273288522

+86 18273288522