Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

Zirconia ceramic are used in shaft, plunger, sealing structure, auto-mobile industry, oil drilling equipment, insulation parts in electrical equipment, ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity. We can supply the products according to customer's drawings, samples and performance requi1

Read More

1. Do different size of Platinum/PT Crucibles as you need.2. Send us design drawing or specification of Platinum/PT Crucibles . Manufacturer of Platinum/PT Crucibles .CS CERMAIC CO.,LTD

Read MoreSiO2 Quartz ceramic crucibles are cost-effective, reusable, easy to clean, and resistant to high temperatures and chemical corrosion, making them suitable for handling various substances. Available in various sizes and shapes.

item no. :

CS-QC-1001Material : SiO₂ Quartz Ceramic

Purity Available : 99.5%

Shape : Conical;Cylindrical;Square

1. High temperature resistance: Quartz ceramic crucibles are made from high-quality quartz material, which offers excellent resistance to extreme temperatures.

2. Low thermal expansion: They have a very low coefficient of thermal expansion, which means they do not expand or contract significantly with temperature changes. This property ensures dimensional stability and prevents cracking or breakage, even when subjected to rapid temperature changes. It allows them to maintain their shape and integrity within a wide range of temperature variations.

3. Chemical inertness: They are highly resistant to chemical corrosion and do not react with most acids, alkalis, or other chemicals.

4. High purity: They have excellent purity levels, as they are typically made from high-grade quartz materials. They have low impurity content, ensuring minimal cross-contamination and maintaining the integrity of the materials being processed.

5. Good thermal conductivity: They have relatively high thermal conductivity, allowing for efficient heat transfer during heating or cooling processes.

6. Easy to clean: They are non-stick and have a smooth, non-porous surface. This makes them easy to clean and eliminates the risk of contaminants adhering to the crucible during use. They can be quickly rinsed or wiped clean, saving time and effort in maintenance.

7. Longevity: Quartz ceramic crucibles have a long operational lifespan due to their excellent thermal and chemical resistance. They can withstand repeated use and exposure to harsh conditions without showing signs of wear or degradation. This results in cost savings and reduces the frequency of crucible replacement.

1. Quartz ceramic crucibles are versatile and highly durable containers made from high-quality fused quartz material.

2. With a smooth and non-contaminating surface, they are chemically inert, making them suitable for handling various substances without causing any unwanted reactions or contamination. Their high purity and low levels of impurities ensure accurate and reliable analysis in scientific experiments.

3. These crucibles are also characterized by their high mechanical strength, ensuring they can withstand regular use without easily succumbing to wear and tear.

4. Quartz ceramic crucibles are lightweight and easy to handle, allowing for easy pouring and transferring of the contents. Their smooth and non-stick surface makes it easy to remove solidified materials without any residue or sticking, facilitating the cleaning process and minimizing waste.

5. Whether used in scientific laboratories, metal casting, or material analysis, quartz ceramic crucibles are a reliable solution for high-temperature applications. Their versatility, durability, and chemical inertness make them an indispensable tool for professionals seeking consistent and accurate results.

Volume(ml)

Cylindrical quartz ceramic crucibles

Item No.

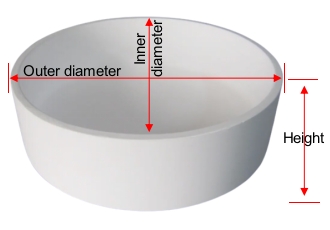

Outer diameter (mm)

Inner diameter (mm)

Height(mm)

Purity

CS-QC-1001

170

60

50

90

99.50%

CS-QC-1002

280

100

80

60

99.50%

CS-QC-1003

469

82

70

130

99.50%

CS-QC-1004

918

120

100

125

99.50%

CS-QC-1005

1379

140

120

130

99.50%

CS-QC-1006

2460

160

140

170

99.50%

CS-QC-1007

3910

200

180

164

99.50%

CS-QC-1008

9890

320

300

150

99.50%

CS-QC-1009

56000

440

420

420

99.50%

Conical quartz ceramic crucibles

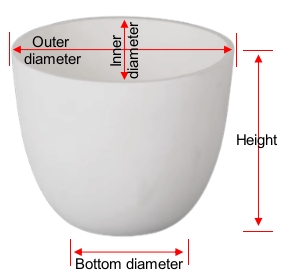

Item No.

Height(mm)

Purity

CS-QC-2001

47

40

30

21

82

99.50%

CS-QC-2002

85

55

45

38

69

99.50%

CS-QC-2003

229

68

58

42

102

99.50%

CS-QC-2004

287

95

75

69

80

99.50%

CS-QC-2005

365

80

70

53

110

99.50%

CS-QC-2006

527

100

80

66

120

99.50%

CS-QC-2007

1103

106

86

77

205

99.50%

CS-QC-2008

1452

120

100

88

200

99.50%

CS-QC-2009

1978

140

120

102

190

99.50%

Square quartz ceramic crucibles

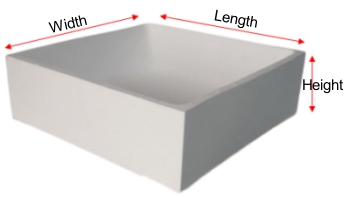

Item No.

Height(mm)

Purity

CS-QC-3001

2900

320

320

48

14

99.50%

CS-QC-3002

3495

320

320

55

14

99.50%

CS-QC-3003

3900

320

320

60

14

99.50%

CS-QC-3004

4761

250

250

100

10

99.50%

CS-QC-3005

5200

320

320

75

14

99.50%

CS-QC-3006

5627

320

320

80

14

99.50%

CS-QC-3007

6050

320

320

85

14

99.50%

CS-QC-3008

7100

300

300

110

14

99.50%

CS-QC-3009

9030

320

320

120

14

99.50%

CS-QC-3010

9890

320

320

130

14

99.50%

CS-QC-3011

10060

300

300

150

14

99.50%

CS-QC-3012

11595

320

320

150

14

99.50%

CS-QC-3013

11911

300

300

175

14

99.50%

CS-QC-3014

14616

300

200

300

10

99.50%

CS-QC-3015

15000

320

320

190

14

99.50%

CS-QC-3016

19600

370

370

185

15

99.50%

CS-QC-3017

20500

420

420

150

15

99.50%

CS-QC-3018

25210

520

520

120

15

99.50%

CS-QC-3019

26250

530

530

120

15

99.50%

CS-QC-3020

30000

530

530

135

15

99.50%

CS-QC-3021

32410

520

520

150

15

99.50%

1. Chemical and Material Analysis: Quartz ceramic crucibles can be used in laboratories for various chemical and material analysis processes. They can be used for melting, calcining, and fusing different substances, allowing researchers to analyze the composition and properties of materials.

2. Metallurgy: They can withstand high temperatures, making them ideal for various metallurgical applications.

3. Glass Manufacturing: They are widely used in the glass manufacturing industry. They can be employed for melting glass batches, refining the molten glass, and shaping it into different forms. The crucibles' high thermal resistance and chemical inertness make them ideal for working with glass.

4. Semiconductor Manufacturing: They find extensive application in the semiconductor industry.

5. Powder Metallurgy: They are utilized in the powder metallurgy process, which involves compacting metal powders and then sintering them at high temperatures to form solid metal components. The crucibles can withstand the high temperatures required for sintering, ensuring efficient and accurate production of powdered metal products.

6. Research and Development: They are widely used in research and development settings for various scientific experiments and investigations. They can be employed in high-temperature reactions, heating or cooling processes, and material synthesis, assisting researchers in exploring new materials and developing innovative technologies.

| Items | Specifications |

| Max Operation Temperature(℃) | 1650 |

| Volume Density(g/cm3) | ≥1.90 |

| Apparent Porosity (%) | ≤15 |

| Room Temperature Compressive Strength(MPa) | ≥50 |

| Room Temperature Flexural Strength (MPa) | ≥20 |

| Thermal Conductivity(W/m·k) (RT~1000℃) | 0.6~1.7 |

| Thermal Expansion Coefficient(℃-1)(RT~1000℃) | ≤0.9×10-6 |

| Crystallinity (vol%) | ≤1 |

Q1. What is a quartz ceramic crucible?

A1: A quartz ceramic crucible is a laboratory tool designed for various high-temperature applications, including melting, heating, and chemical reactions.

Q2. How durable is a quartz ceramic crucible?

A2: Quartz ceramic crucibles are known for their high durability and resistance to thermal shock. They can withstand rapid temperature changes and repeated heating and cooling cycles without cracking or breaking.

Q3. . Are quartz ceramic crucibles reusable?

A3: Yes, quartz ceramic crucibles are generally reusable. After each use, they can be cleaned and prepared for subsequent applications.

Q4. Are there different sizes and shapes available for quartz ceramic crucibles?

A4: Yes, quartz ceramic crucibles are manufactured in various sizes and shapes to suit different laboratory needs. Common shapes include cylindrical, conical, square and dish-shaped crucibles. It is important to select the appropriate crucible size and shape based on the specific application requirements.

Q5. Can quartz ceramic crucibles be customized for specific applications?

A5: Yes, many manufacturers offer custom options for quartz ceramic crucibles to meet specific requirements such as volume capacity, special coatings, or additional features. It is recommended to consult with the manufacturer or supplier for any customization needs.

1. Before you clean the quartz ceramic crucible, it is important to make sure that it has cooled completely.

2. Start by brushing off any excess debris with a dry, soft-bristled brush.

3. If the crucible is still dirty, you can use a few drops of mild soap to help loosen any grime and dirt.

4. Gently scrub the surface of the crucible with a soft-bristled brush, rinse the crucible with clean, warm water.

5. Allow the quartz ceramic crucible to air dry.

1. Visual inspection: Perform a visual inspection of the crucible. Look for any cracks, chips, or other physical damage on the surface. Also, check for any discoloration or unusual marks.

2. Check the dimensions: Measure the outer dimensions of the crucible using a caliper or ruler to ensure it matches the specifications. Check the inner dimensions as well to verify the capacity of the crucible.

3. Tapping test: Gently tap the crucible with a metal object, such as a small hammer or a metal rod. Listen for any unusual sounds, such as a dull thud or a high-pitched tone, which may indicate hidden cracks or defects.

4. Chemical resistance test: If necessary, expose the crucible to chemicals that it will come into contact with during its use. Observe if there are any signs of chemical reactions, discoloration, or deterioration of the crucible's surface.

1. We offer personalized and customized services to meet your individual needs.

2. We are experienced professionals with a proven track record of success.

3. We provide excellent customer service and timely responses to all inquiries.

4. We have competitive rates and work to ensure that you get the best value for your money.

5. We use the latest technology and tools to ensure that your project is completed to the highest standards.

6. We take pride in our work and strive for complete customer satisfaction.

Quartz Ceramic Crucibles Bowls Silica Crucibles for Melting Gold

Quartz Ceramic Crucibles Bowls Silica Crucibles for Melting Gold

Quartz ceramic crucibles bowls silica crucibles are cost-effective, reusable, easy to clean, and resistant to high temperatures and chemical corrosion, making them suitable for handling various substances. Available in various sizes and shapes.

Fused Silica Crucible Quartz Ceramic Crucibles for Melting Gold

Fused Silica Crucible Quartz Ceramic Crucibles for Melting Gold

Fused quartz ceramic crucibles are mainly used for the melting of platinum, gold,and other high-temperature alloys,with high purity,corrosion resistance, and strong thermal shock resistance. Available in various shapes and sizes.

Ceramic Fillinf Valve Alumina Filling Valve Aluminum Oxide Filling Valve

Ceramic Fillinf Valve Alumina Filling Valve Aluminum Oxide Filling Valve

The alumina ceramic filling valve is a precision-engineered component made from high-purity alumina powder through processes such as shaping and sintering. It is specifically designed for use in automatic filling machines, where it regulates and controls flow rates to achieve accurate and automated filling operations.

ALUMINUM DSC AUTOSAMPLER SEAL PANS equivalent to Shimadzu 346-68518-91

ALUMINUM DSC AUTOSAMPLER SEAL PANS equivalent to Shimadzu 346-68518-91

For DSC-60A series, DSC-60A plus series, and DTA-50 instruments. Manufacturer of SHIMADZU OEM consumables.

300ul Linseis STA Special Shape Alumina Pans for Linseis (Sample Pans)

300ul Linseis STA Special Shape Alumina Pans for Linseis (Sample Pans)

300ul Linseis STA special shape alumina pan for Linseis STA DSC and TGA measurements. Manufacturer for Linseis crucibles and sample pans.

Round Zirconia Sintering Dental Saggar with Lid

Round Zirconia Sintering Dental Saggar with Lid

Zirconia sagger is a type of sintering tray widely used in muffle furnaces, tube furnaces, and tunnel furnaces.

0.3ml Ceramic sampel crucible equivalent to NGB810411 for Netzsch DSC 404 F1/F3 Pegasus, STA 449 F1/F3/F5 Jupiter®

0.3ml Ceramic sampel crucible equivalent to NGB810411 for Netzsch DSC 404 F1/F3 Pegasus, STA 449 F1/F3/F5 Jupiter®

NGB810411 Netzsch Alumina crucibles Special shape for Netzsch DSC 404 F1/F3 Pegasus, STA 449 F1/F3/F5 Jupiter® TDA DSC and TGA measurements. Manufacturer for Netzsch crucibles and sample cups. Netzsch Instruments good alternative DSC sample pans.

High-Temp Zirconia Ceramic Foam Filter For Steel Casting

High-Temp Zirconia Ceramic Foam Filter For Steel Casting

Zirconia Ceramic Foam Filter features a unique three-dimensional porous structure, renowned globally for its exceptional heat resistance. Withstanding temperatures up to 1700°C, it stands unmatched in its ability to perform under the harshest conditions.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522