Ceramic Crucible Leco 528-018. Manufacturer of carbon sulfur crucible & cs crucible for LECO CS230. Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO528-018/002-301/002-302 Elementar 905.200.380.001 AN. Used for Carbon sulfur Analyzer Elemental Analysis.

Read More

Alumina tubes both sides open are commonly used in various industrial and laboratory applications. They are ideal for use in processes such as heating, cooling, and drying, and can offer superior thermal and electrical insulation.

Read More

Achieve unparalleled levels of purity with our Bone Ash Cupels. Engineered to remove impurities and unwanted elements, these cupels enable you to extract the true essence of your precious metals.

Read More

Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications.

Read More

Alumina pipes advantage:high heat resistance,good cold-resistance heat-resistance,resistance to acid and alkali corrosion. Long service life. OEM is accpected.

Read More

Alumina crucible and boat are wildly used in laboratory and industrial analysis as well as metal and nonmetal material sample melting.Available in various sizes and shapes.

Read More

Circle alumina ceramic rods have a higher strength to weight ratio than other ceramics, and can be used to manufacture lighter and stronger parts.Available in a variety of sizes and shapes.

Read More

952018.906 100μl Platinum/Pt Crucibles(Sample Pans) for TA Instruments TA Q500/Q50/TGA 2950/2050. Manufacturer for TA crucibles and DSC sample pans. TA Instruments tga analyser good alternative sample cups.

Read More

ME-00024123 DSC Alumina crucibles sample pans for Mettler TGA/sample robot measurements. Manufacturer for Mettler Toledo crucibles,sample pans and dsc consumables.

Read More

20 ml Large Ceramic Crucible 529-047 / 621-331 for LECO, Alpha AR9047. Manufacturer of TGA ceramic crucible for LECO TGA 500/501/601/701, MAC 400 / 500. TGA alumina crucible/pans for TGA-Thermogravimetric Analyzer analysis TGA measurement.

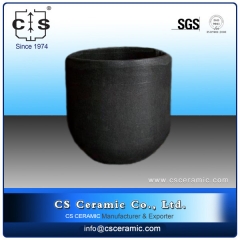

Read More1. Do different size of graphite parts as you need.2. Send us design drawing or specification of graphite Crucibles.Manufacturer of graphite Ceramic .CS CERAMIC CO.,LTD

item no. :

CS-G-05Color :

Black

4. Widely used in such fields as industrial furnaces, mono-crystalline silicon machinery, mono-crystalline silicon machinery, electron, semi-conductor, metallurgy, oil, chemistry, textile, electrical machinery, electrical equipment, electrical furnace, traffic, communication industry, medicine, etc.

If need open new mould, please send us detail specification and design drawing firstly, we'll reply you in 24 hours. Contact email: info@csceramic.com

Small Furnace Graphite Crucible for Melting Gold

Small Furnace Graphite Crucible for Melting Gold

1. Do different size of graphite parts as you need.2. Send us design drawing or specification of graphite Crucibles.Manufacturer of graphite Ceramic .CS CERAMIC CO.,LTD

Small Capacity High Density & Purity Graphite Crucible Metal Graphite

Small Capacity High Density & Purity Graphite Crucible Metal Graphite

1. Do different size of graphite parts as you need.2. Send us design drawing or specification of graphite Crucibles.Manufacturer of graphite Ceramic .CS CERAMIC CO.,LTD

High Purity Graphite Part Do Special OEM Graphite Crucible

High Purity Graphite Part Do Special OEM Graphite Crucible

1. Do different size of graphite parts as you need.2. Send us design drawing or specification of graphite Crucibles.Manufacturer of graphite Ceramic .CS CERAMIC CO.,LTD

OEM Custom Big And Small High Purity Graphite Crucible For Sale China Supplier Factory Price

OEM Custom Big And Small High Purity Graphite Crucible For Sale China Supplier Factory Price

1. Do different size of graphite parts as you need.2. Send us design drawing or specification of graphite Crucibles.Manufacturer of graphite Ceramic .CS CERAMIC CO.,LTD

250μl Ceramic Sample Pans for TA SDT Q600 PN 952018.909

250μl Ceramic Sample Pans for TA SDT Q600 PN 952018.909

250μl Alumina crucibles for TA Instruments TA SDT Q600. Manufacturer for TA crucibles and DSC sample pans. TA Instruments good alternative sample pans.

30μl Disposable high pressure crucible with lid/seal gold plated for Setaram

30μl Disposable high pressure crucible with lid/seal gold plated for Setaram

30μl Setaram disposable high pressure crucible with lid/seal gold plated. Manufacturer of Setaram crucible consumables and instruments.

900μl Alumina crucibles only for Mettler Toledo (Sample pans)

900μl Alumina crucibles only for Mettler Toledo (Sample pans)

Big Alumina crucibles sample pans for Mettler DSC and SDTA measurements. Dsc sample tray and Thermal analysis crucible consumable sample tray for DSC &TGA analysis. Manufacturer for Mettler Toledo crucibles and sample pans.

Hangdown Wire Tare 957082.901 for TA Tga Sample Wire for Q5000IR/Q5000SA/ Discovery TGA; Tare Wire for Q5000SA

Hangdown Wire Tare 957082.901 for TA Tga Sample Wire for Q5000IR/Q5000SA/ Discovery TGA; Tare Wire for Q5000SA

957082.901 Platinum-Hangdown Platinum/Pt Crucibles Platinum/Pt Sample Pans for TA Tga Sample Wire for Q5000IR/Q5000SA/ Discovery TGA; Tare Wire for Q5000SA. Manufacturer for TA crucibles and DSC sample pans. TA Instruments good alternative sample cups.

the professional team to service !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522